Poduct Description

High performance waterjet diamand orifice waterjet spare parts

Good diamond is the key,

Synthetic orifices have a good price,but service life is shot,about from 10 to 90 hours,and easy broken,so high quality waterjet orifice Is fundamental to reducing failures.

More waterjet orifice infaormation please contact WIN-WIN company,we will have professional technicians explain to you.

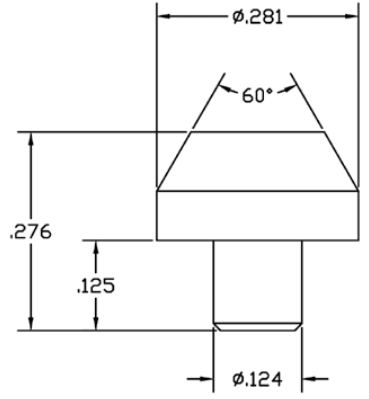

Item number: 49888902

Specification: .008″ or 0.20mm inner diameter

This hold with a sharp top corner that creates the coherent jet necessary for cutting.

Related Orifices for Pure Water Cutting 4,100 bar Diamond Orifice

| 0.003" / 0.07 mm 49888852 0.004" / 0.10 mm 49888860 0.005" / 0.12 mm 49888878 0.006" / 0.15 mm 49888886 0.007" / 0.17 mm 49888894 0.008" / 0.20 mm 49888902 0.009" / 0.23 mm 49888910 0.010" / 0.25 mm 49888928 0.012" / 0.30 mm 49888936 0.013" / 0.33 mm 49836786* 0.014" / 0.35 mm 49888944 0.015" / 0.38 mm 49888951 0.016" / 0.40 mm 49888969 0.018" / 0.46 mm 49888977 0.019" / 0.48 mm 20436198* 0.020" / 0.51 mm 49888985 0.022" / 0.56 mm 49888993 |

A diamond orifice is a specialized component used in waterjet cutting systems to create a focused jet of water for cutting materials. It is called a "diamond" orifice because it is typically made from a synthetic diamond material.

Diamond orifices are preferred in waterjet cutting applications that require high precision and durability. Compared to traditional orifices made from materials like ruby or sapphire, diamond orifices offer several advantages:

Hardness: Diamonds are one of the hardest materials known, which means they have excellent wear resistance. Diamond orifices can withstand the erosive forces of the high-pressure water jet for a longer time, resulting in extended operational life.

Precision: Diamond orifices can be manufactured with very tight tolerances, ensuring consistent and precise jet formation. This is crucial for achieving accurate cuts, especially in applications that demand high levels of precision.

Chemical Inertness: Diamonds are chemically inert, meaning they are resistant to corrosion and chemical reactions. This property makes diamond orifices suitable for cutting materials that may contain corrosive elements or chemicals.

Heat Dissipation: Diamond has excellent thermal conductivity, which helps dissipate heat generated during the cutting process. This feature is particularly beneficial when cutting materials that are prone to heat-related damage, as it helps minimize the heat-affected zone (HAZ) and reduces the risk of thermal distortion.

Diamond orifices are commonly used in waterjet cutting systems for various industrial applications, including aerospace, automotive, electronics, and precision machining. They are especially useful when cutting hard and abrasive materials like metals, ceramics, and composites, where the durability and precision of the orifice are crucial for maintaining cutting performance over extended periods.

Contact WINWIN waterjet,we have all the orifices you need in stock,we can ship to you within one day delivery time.

If you have want to know more details of WINWIN waterjet orifices.please feel free to send us the inquiry,we will get back to you within 24 hours.

wwaterjet

wwaterjet