WIN-WIN waterjet cutting machine cantilever waterjet working platform is integrally processed by a large 5-axis CNC machining center. Both X-axis and Y-axis girder adopt the double-layer dustproof and waterproof structure and are driven by high-quality ball screw guide rails and bus CNC system.

What is waterjet cutting?

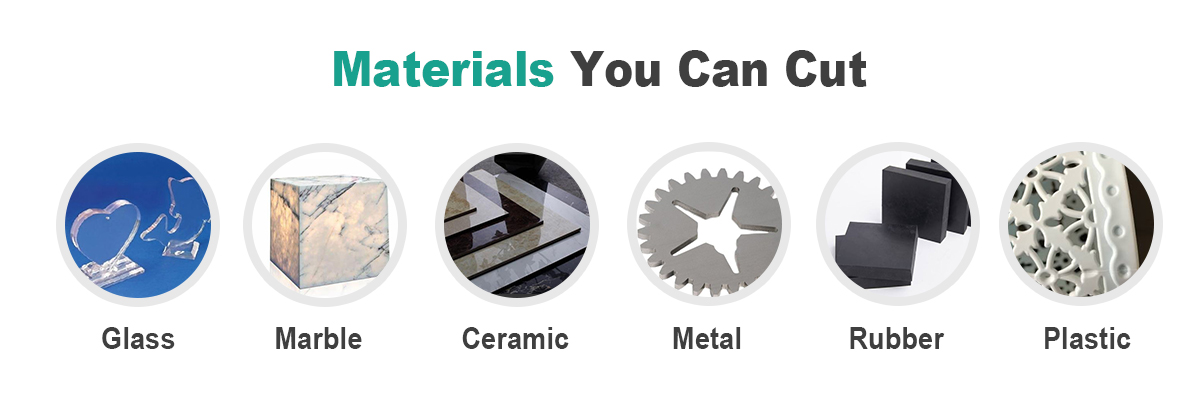

Water cutting is a processing method that uses high-speed water flow to cut mechanical materials. Water cutting uses high-pressure water flow to increase the water flow speed to supersonic speed to form a jet, which relies on the high-speed impact and grinding effect of the water flow to cut the material. Water cutting has the advantages of no pollution, high efficiency, and high precision, and is widely used in cutting and processing of stone, metal, ceramics, plastics, rubber and other materials.

Material range for waterjet cutting

Waterjet cutting technology is an efficient and precise cutting method, suitable for a variety of materials, and has a wide range of applications, including but not limited to the following aspects:

Metallic material

Steel: Waterjet cutting is suitable for all types of steel, including ordinary carbon steel, stainless steel, alloy steel, etc. Waterjet cutting does not produce thermal deformation and is suitable for fine cutting of metal.

Aluminum Alloys: Waterjet cutting also excels with aluminum and its alloys. Since waterjet cutting does not cause heat-affected zones, it is suitable for high-precision cutting requirements for aluminum.

Stone

Marble and granite: Waterjet cutting can be used to cut stones such as marble and granite to keep the cutting edges flat and reduce cracks and damage.

Ceramics: Since waterjet cutting does not cause thermal stress, it is suitable for high-precision cutting of brittle materials such as ceramics.

Rubber and plastic

Rubber products: For the cutting of rubber, waterjet cutting is an ideal choice because it does not cause heat and vibration and can maintain the quality of the rubber cut edge.

Plastic materials: Suitable for all types of plastic materials, such as polyethylene, polypropylene, etc. Waterjet cutting avoids stress and allows for precise cuts in plastics.

composite materials

Carbon fiber composite materials: Waterjet cutting is very effective for cutting composite materials such as carbon fiber, maintaining the quality of the cutting edge and avoiding fiber damage.

Fiberglass: Waterjet cutting is suitable for high-precision cutting of fiberglass and can maintain the strength and integrity of the material.

food materials

Cake, bread and other foods: Waterjet cutting can be used in the food industry to perform fine, non-destructive cutting of cakes, bread and other foods.

In general, waterjet cutting technology is widely used in various materials such as metal, stone, rubber, plastics, composite materials and food. Its advantages are high precision, low thermal impact, less vibration, etc., so it is important in different fields. application value.

Does waterjet cutting use pure water?

What is used in the water cutting process is not pure water, but pre-treated water. Water cutting machines are usually equipped with equipment such as particle filters and water softeners to treat water to ensure water quality. The pretreated water is pressurized by a high-pressure pump and then sprayed out to cut and process materials.

What impact does water purity have on waterjet cutting quality?

Although water cutting does not use pure water, the purity of the water has a great impact on the cutting quality. Impurities and minerals in the water are easily deposited during the cutting process, affecting the smoothness of the nozzle and the life of the machine. At the same time, the hardness of the water will also have an impact on the cutting quality. Calcium and magnesium ions in hard water easily precipitate on the surface of the material, forming white water marks, which affects the appearance and quality of the material. Therefore, the correct use and maintenance of water cutting pretreatment equipment is very important.

In short, water cutting is an efficient and environmentally friendly processing method that uses high-pressure water flow to cut materials without generating heat or chemical reactions. Although water cutting does not use pure water, the purity of the water has a great impact on the cutting quality, so the correct use and maintenance of the pretreatment equipment is very important.

Advantages & Features of this waterjet cutting machine

Ground loading platform

The cutting table adapts latest loading design, the max load-bearing is 1000 kg, Equipped with a floor-standing turning platform point, which can automatically load and unload materials from three directions.

Floor-type loading system for large piece of material cutting of 4 meters * 2 meters

Hydraulic lifting and some other designs can meet the requirement of metal cutting

Cantilever structure

Cantilever structure, cutting platform and operating platform are designed to be separated to avoid the overall deformation of the waterjet cutting machine due to the influence of the water tank load. The water tank WINWIN is made of 6mm thick steel plate. The equipped grid width is 80cm. It adopts an adjustable structure to make it more convenient for customers to use.

Good stability and guaranteed lifespan

The entire machine adopts a fully protective structure made of stainless steel, so it can work stably in any complex environment. The X-axis material of the water cutting machine platform is an aluminum alloy profile, which has high strength, is light in weight, and will not be permanently deformed. The Y-axis of the cutting machine platform uses a linear guide structure, which can ensure the stability of operation. The linear guide rail of large platforms is more stable than the screw structure.

| Series | 5A-4020 Water Jet | Type | Cantilever Type |

| Cutting Precision | ±0.1mm | Control Accurcy | ±0.01mm |

| RE-Positioning Accuracy | ±0.05mm/m | Travel Of Z Axis | 200mm |

| Cutting Speed | 11000mm/min | Motor | 30kw / 40HP |

| Table Size | 4000mmx2000mmx200mm | Certificate | CE ISO |

If you are interested in abrasive waterjet cutting machine,please feel free to contact us!

wwaterjet

wwaterjet