CNC Waterjet cutting machine are widely used in industrial and medical fields. Let’s introduce the uses of water jets. Let’s talk about them from two fields.

The first is industrial waterjet cutting, which can cut a variety of materials, such as:

Waterjet Cutting Stone

Stone is the most commonly used in home decoration.

Granite, marble, or other stone (usually a combination of quartz and epoxy) used in kitchens and bathrooms. The initial pattern for stone countertops is usually cut using a abrasive waterjet cuttingt. Stone, cut into various shapes, can be put together into ornate patterns to beautify the floors of buildings, walls, borders around rooms, tabletops or works of art designed as graphic works in the house. waterjet cutting construction materials are heavily used in these applications. Whenever you see ornate geometric shapes such as stars, plants, abstract or graceful geometric shapes in a stone setting, it is almost always cut with a abrasive waterjet cutting. The characteristics of the abrasive waterjet are simple and easy to use, creating conditions for the majority of architects to give full play to their level and ability. Visualize the designer's ideas.

Waterjet in Compound Cutting

Composite materials are high-tech products with a wide range of uses, such as carbon fiber materials for automobiles, which have high requirements on the shape of materials, and the ratio of weight and strength is very different. Not metal, lighter than metal, but stronger. Due to this characteristic, general cutting methods are not suitable for composite materials, such as lasers, chainsaws, etc. Composite materials such as glass fiber and carbon fiber reinforced plastics have high requirements on the cutting process. If heat is generated during cutting, the material will be burned and deformed, and at the same time, harmful gases will be generated, which will be harmful to the body and the environment. make an impact. However, waterjet cutting can completely avoid these problems. The cutting process has no heat, no smoke and dust, which belongs to cold cutting

Dissimilar Metal Cutting

In the field of metal materials, many mild steels (carbon steels), titanium metals, and aluminum need to be cut into parts. As a result, abrasive waterjet cutting many mild steels and aluminum. However, with the development of science and technology, the requirements for cutting are very high. For example, one-piece molding, no secondary processing, no welding, no deformation, high precision and other requirements.

Advanced technology is due to the use of scenarios often have higher requirements such as aerospace, subway, aircraft, ships and other industries.

The processing of special metals is very difficult and complicated, both precision and efficiency must be considered. For example, win win waterjet cutting 90000psi cuts 300mm thick metal, and uses ultra-high pressure water flow to cut metal

Waterjet Cutting Insulation

Insulation and heat insulation materials in buildings are also difficult to cut

The insulating materials used in HVAC, automobiles or walls of buildings and houses are very easy to be crushed due to their special properties, and general cutting methods cannot meet the requirements. Pure water's water jets can cut fiberglass very quickly, even thick fiberglass insulation that you might have in the attic of your home. Cut patterns in the HVAC and automotive industries and use pure water jets for simple cuts of thick, fluffy insulation cuts.

Water jet cutting cement board

Cement boards are commonly used as building products. Usually between 2 and 5 cm thick, it provides strength, moisture resistance, and can be made into various shapes. It is commonly used in building siding, as a substrate for wall tiles or as a lining for floors. Cement board can be cut with a saw, which is the obvious cutting tool of choice on the job site. However, in a factory, it is often desirable to cut cement board while it is in its uncured state (sometimes called the green state). This is where pure waterjet cutting shines. Just like slitting paper, pure waterjets can be easily integrated into production lines to slit cement boards prior to final curing. And similar to stone, after the cement board has cured (hardened), it can be cut into complex shapes using a water jet grinder.

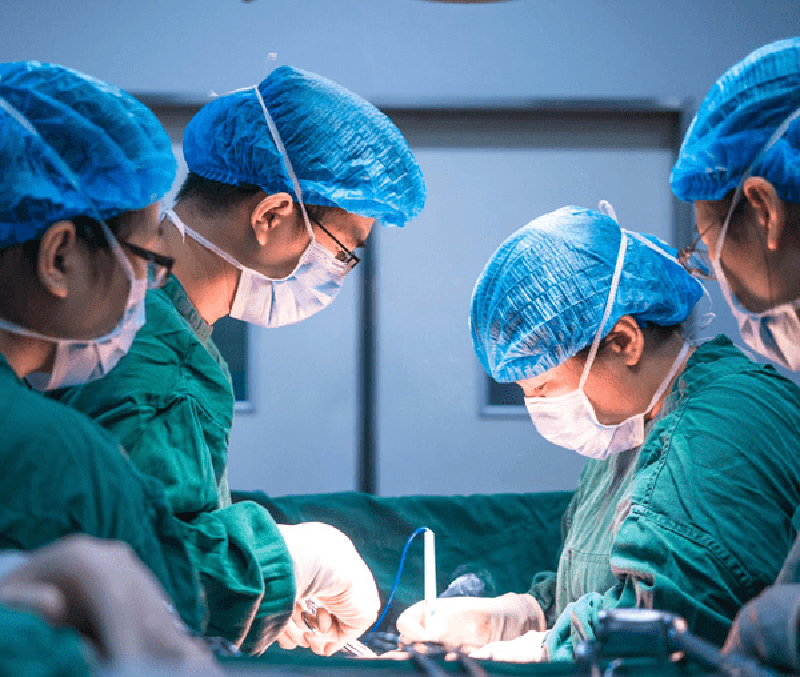

Applications in the medical field:

Water jet, the full name of spiral water jet, is to accurately control the water pressure through its unique pressure generation system, so that the water flows through the high-pressure conduit to the nozzle, forming a spiral fine high-pressure water jet. Various operations, including partial nephrectomy, total mesorectal resection, parathyroid gland and bone tumor surgery, etc., have also made great progress in the field of hepatobiliary surgery in recent years.

Features of traditional surgical debridement: 1. Resection is fast and time-saving, but necrotic tissue cannot be removed in a precise and controllable manner. In the case of necrotic and active tissue wounds, it is impossible to distinguish, and only one size fits all, and multiple resection arrangements cannot be avoided. 2. Special parts are limited (such as eyelids, ears, finger webs, face, limbs, etc.), and the wound needs to be expanded if necessary; 3. Excessive excision tissue will cause a lot of bleeding; 4. It is not suitable for trauma debridement of ischemic ulcers.

High-pressure pulse flushing and debridement: 1. High-pressure pulse force tends to leave the removed tissues and fragments on the wound; 2. It cannot provide a clear surgical field of view; 3. It is easy to cause pollution to the surgical environment; 4. It will form tiny fragile tissues (such as 5. It is easy to embed bacteria into the soft tissues of the wound, making local tissues susceptible to infection and affecting later healing.

Ultrasonic debridement features: 1. The ultrasonic knife head only has the function of incision, and the suction function is achieved by the negative pressure suction tube; 2. It requires a variety of high-cost and inconvenient debridement processes; 3. It can only remove loose tissue Necrotic tissue (such as carrion) 4. Cannot effectively debride the wound, affecting the healing preparation of the wound bed.

Waterjet debridement technology introduction: The hydrodynamic debridement system uses tissue separation technology to allow doctors to accurately select, cut and resorb inactivated tissues, bacteria, pollutants and biofilms on the wound surface. Use high-speed high-pressure saline water flow to achieve the best surgical debridement, move the handle on the wound surface to make tangential motions, and the blade is the same as thin saline mist to remove inactivated tissues, bacteria and debris-separate surrounding active tissues, in a fast Preparing for a cleaner, more consistent wound bed removes multiple barriers that prevent wound healing. The fine high-pressure water beam can be highly coagulated without generating water mist, and the operation is relatively simple; it does not directly contact with the tissues, maximizing the protection of blood vessels, bile ducts, lymphatic vessels and nerves, etc.; the field of vision is clear, shortening the operation time and reducing the amount of bleeding.

The new technology of medicalwaterjet cutting uses high-pressure water flow to cut tissue, which has the advantages of less trauma, less bleeding, and high selectivity. In partial nephrectomy, the use of waterjet cutting technology can avoid the process of blocking the renal pedicle in conventional laparoscopic partial nephrectomy, avoiding renal function damage caused by warm ischemia, and truly realizing "zero ischemia" resection Kidney tumors. In bladder tumor resection, water is injected at the base of the tumor to separate the tumor from normal tissues, and then the tumor is completely removed with a water jet, which has the advantages of complete, complete, and clean resection of the tumor.

wwaterjet

wwaterjet