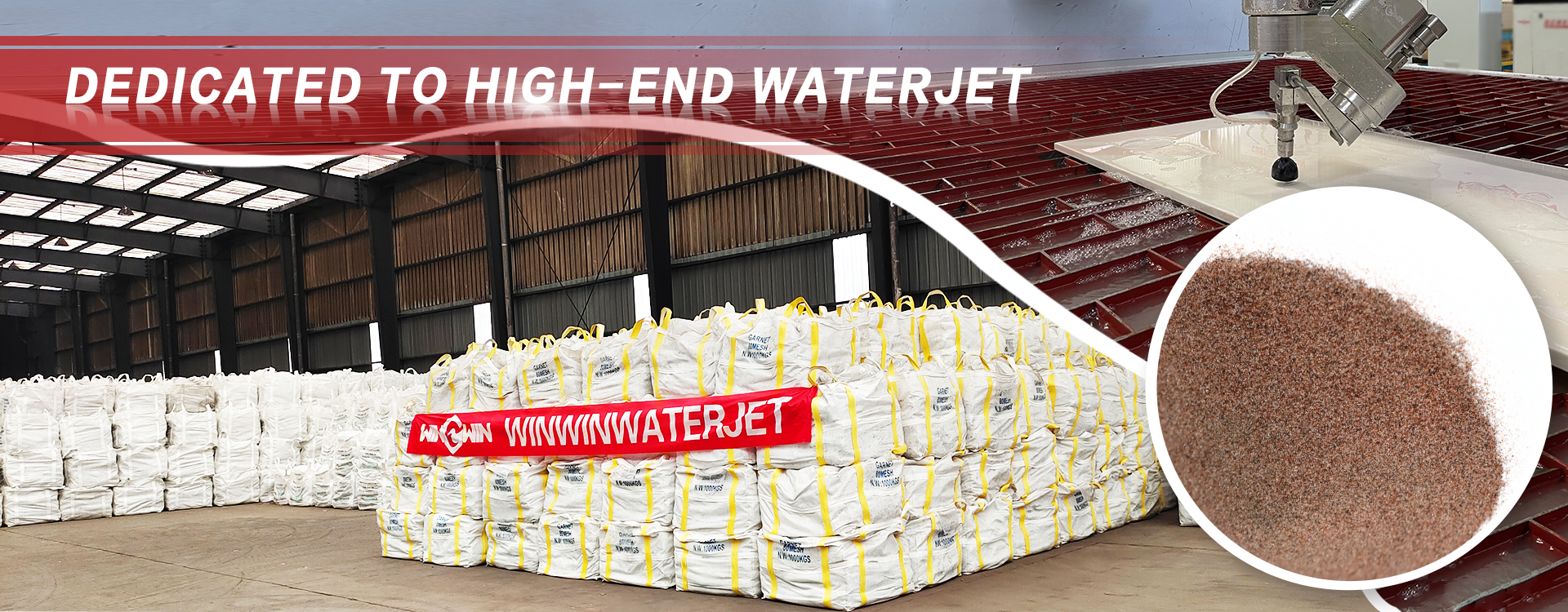

The video is about abrasive is shipped from WINWIN factory, and the customer purchases 10 containers at one time.

The customer has multiple water cutting equipment, equipped with ultra-high-pressure machines for cutting steel. They need abrasive that can work under 90,000 high pressure for a long time. They have high requirements for the quality of the abrasive. Under such high standards, the customer started using it for the first time. WINWIN has been purchasing abrasive here for a long time. Let’s learn about the classification of abrasive and how to choose water cutting abrasive.

Classification of abrasive:

·Size of Water Jet Abrasive

o1. 80 mesh (200 microns)

o2. 120 mesh (125 microns)

o3. 220 mesh (63 microns)

o4. 320 mesh (45 microns)

What abrasive is used in water jet cutting?

Popular abrasive particle options in waterjet cutting are silicon carbide, aluminum oxide, abrasive, and garnet. Garnet abrasive is the most common abrasive particle used due to its physical properties.

With the rapid development of economy, water cutting is widely used in stone, metal, glass, ceramic cutting and other fields. In this process, garnet waterjet abrasive plays an important role. Pomegranate abrasive is a kind of abrasive made from natural pomegranate seed ore after crushing and screening. Its main component is garnet (alumina garnet), and it also contains a certain amount of elements such as silica, titanium dioxide and iron. Garnet abrasive has uniform particle shape, high hardness and wear resistance, and is suitable for use as water jet cutting abrasive. Garnet abrasive cutting has low cost, high cutting accuracy, and wide cutting range. Its excellent characteristics are favored in water jet cutting. The majority of customers' unanimous praise.

Do all water jets use abrasive?

For lighter materials, pure waterjet cutting—that is, without abrasives—is often preferred, but, for harder materials like steel, very fine abrasive materials are often added to the water to speed cutting.

Many people do not have a complete concept of pure waterjet cutting and abrasive waterjet cutting. In fact, the difference between the two is whether there is a abrasive tube. The pressure of pure waterjet gas cutting is relatively small, and the loss during cutting is relatively low, which can save production costs. The waterjet cutting speed is very fast, which can improve the cutting efficiency.

Garnet abrasive water jet cutting mainly sprays garnet abrasive at high speed to achieve the purpose of cutting. The cutting force of garnet abrasive is thouabrasives of times that of pure water jet. Garnet abrasive waterjet cutting has a wider cutting range and can cut metal, ceramics, composite materials, stone and other hard objects with very good cutting effects.

What kind of abrasive is used in water jets?

Most water jets rely on an abrasive medium (think abrasive) mixed with water to cut through raw material. The most common type of abrasive is garnet, which comes in a variety of strains, and ranges from a very fine consistency to coarser options.

Water jet cutting abrasive uses garnet abrasive with uniform particles, high hardness, and no impurities. Garnet abrasive has high cutting efficiency, does not block the abrasive pipe, and the cutting is stable and very smooth. The commonly used models of garnet abrasive for water jet cutting are: : 60#, 80#, 100#, 120#.

The most commonly used 80 mesh, 80 mesh garnet abrasive is often used to cut special-shaped processing of various metal materials such as ceramic tiles, marble, rock slabs, stainless steel, aluminum, carbon steel plates, copper, titanium alloys, ceramic tiles, stone, rubber, Glass, wood, etc., achieving a high-quality balance in cutting speed and cutting surface accuracy, it is a commonly used water cutting abrasive.

What are the advantages of garnet abrasive for waterjet cutting?

.High hardness: The hardness of garnet abrasive is high, which can effectively provide cutting force during the cutting process and maintain the stability of the cutting board. High-hardness garnet abrasive can also meet the cutting needs of materials of various hardnesses, including metal, stone, ceramics, etc.

.Strong wear resistance: During the waterjet cutting process, the garnet abrasive particles will continue to wear, but due to its strong wear resistance, the stability and durability of the cutting effect can be maintained. This allows garnet abrasive to maintain high cutting efficiency during long-term cutting operations.

. Uniform particle size: Pomegranate abrasive particles have a relatively uniform particle size distribution, which is beneficial to the suspension and transportation of abrasive in the water flow during the cutting process. Uniform abrasive particle size can ensure the consistency and stability of cutting quality.

.Fast cutting speed: Due to the hardness and wear resistance of garnet abrasive, the water flow generates high pressure when interacting with the abrasive material, and forms a strong cutting force. This enables the garnet used in waterjet cutting to quickly cut various materials and improve work efficiency.

.Reliable supply: As one of the common water jet cutting abrasive materials, garnet abrasive has a relatively stable market supply. Users can choose regular garnet abrasive suppliers based on actual needs to ensure the quality of the abrasive and the reliability of supply.

To sum up, garnet abrasive used for water jet cutting has the characteristics of high hardness, wear resistance and uniform particle size. It can provide stable cutting force and fast cutting speed, and is suitable for cutting needs of a variety of materials.

How to choose the right water jet abrasive?

1. Select the appropriate waterjet abrasive: According to the hardness and thickness of the material to be cut, select the appropriate particle size and type of waterjet abrasive to avoid unnecessary damage to the material by using the wrong abrasive.

2. Keep the abrasive clean: During use, clean the abrasive at any time to prevent impurities and other contaminants from entering the material or entering the waterjet system, affecting the cutting effect.

3. Control water pressure and water volume: Waterjet abrasive cutting requires the use of a large amount of high-pressure water flow. On the premise of ensuring the cutting effect, the water pressure and water volume must be reasonably adjusted to avoid the problem of too strong or too weak water flow.

4. Maintain the waterjet system: Keeping the waterjet system clean and operating normally, regularly replacing abrasives and cleaning the system can extend the life of the equipment and improve cutting accuracy and efficiency.

5. Safe operation: Waterjet abrasive cutting is a high-risk operation and must be carried out in strict accordance with operating procedures and safety standards. Safety operation guidelines must be followed to ensure the safety of personnel and equipment.

wwaterjet

wwaterjet