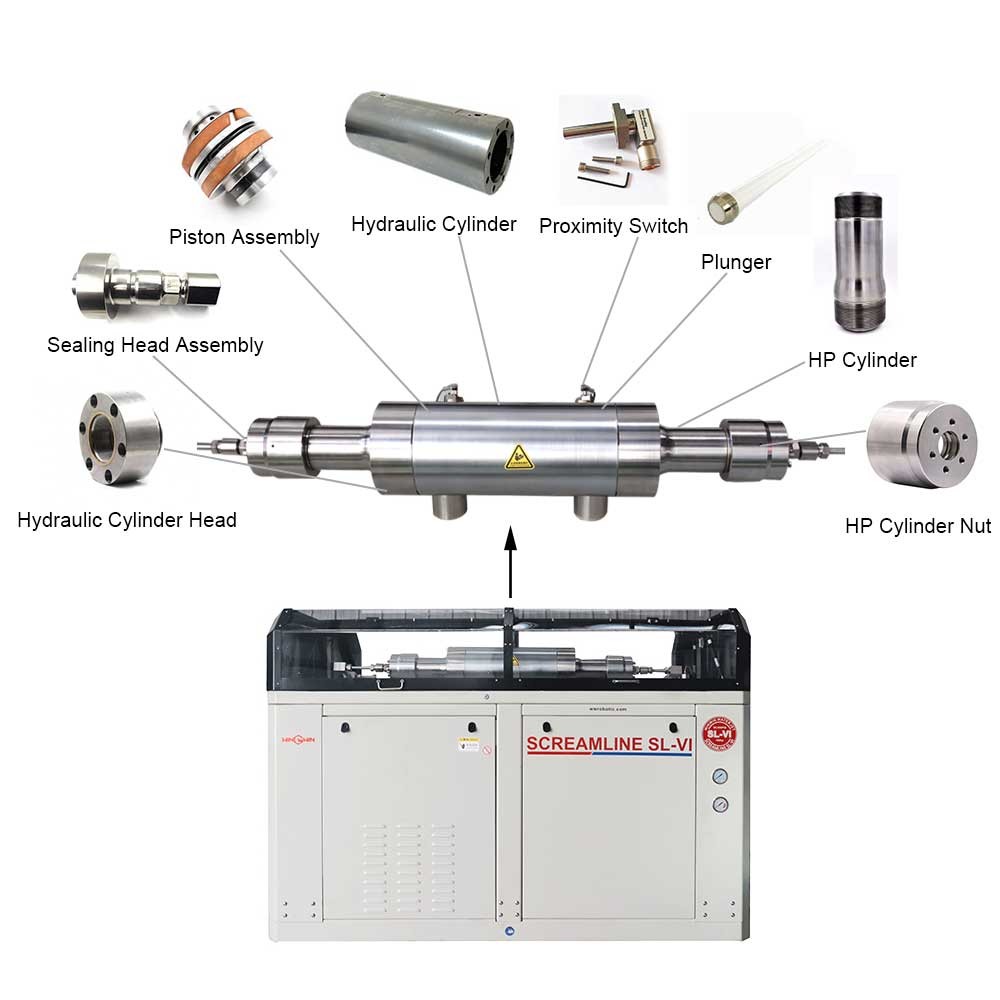

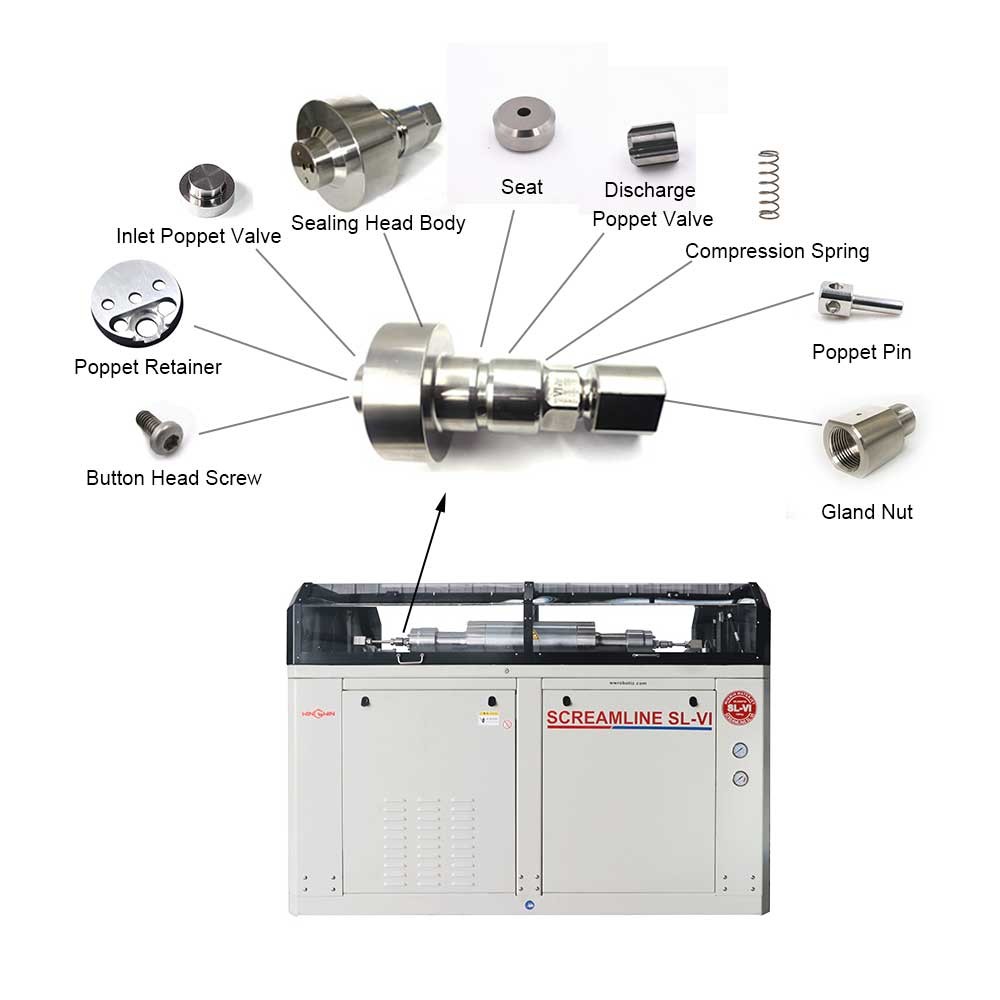

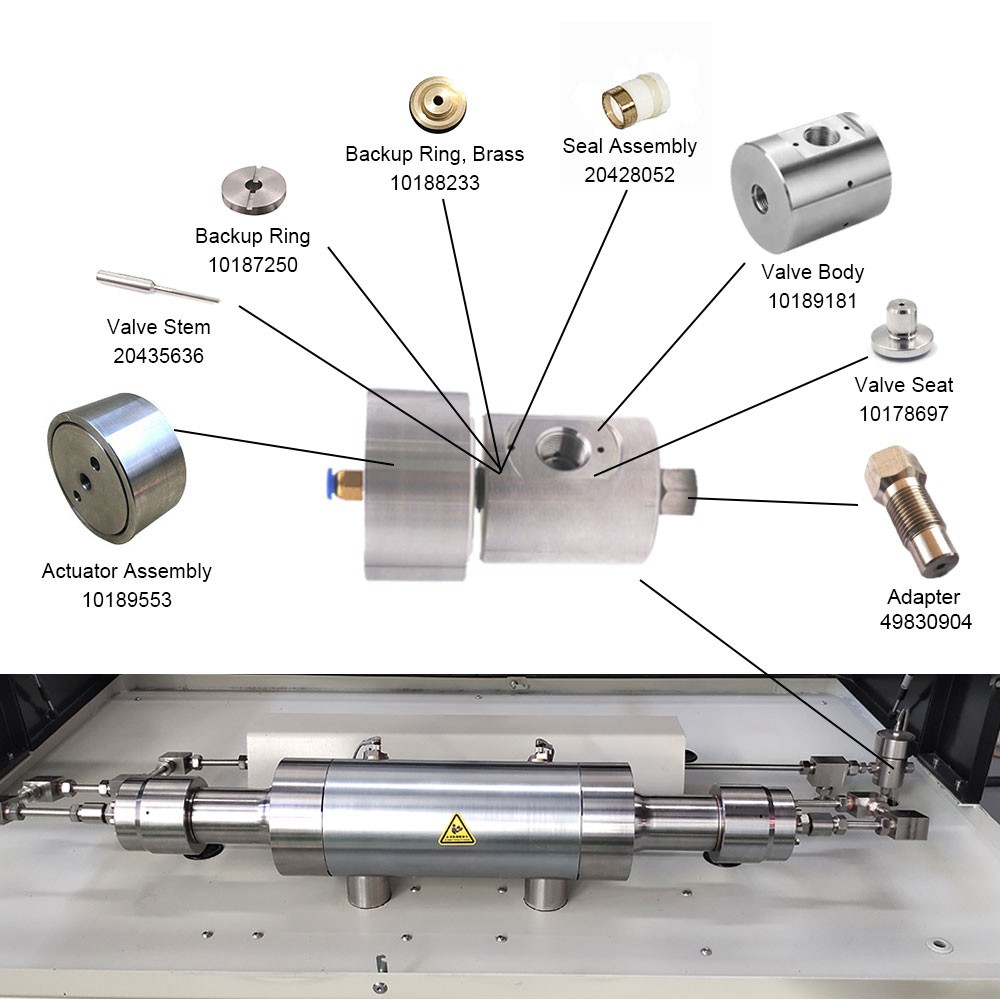

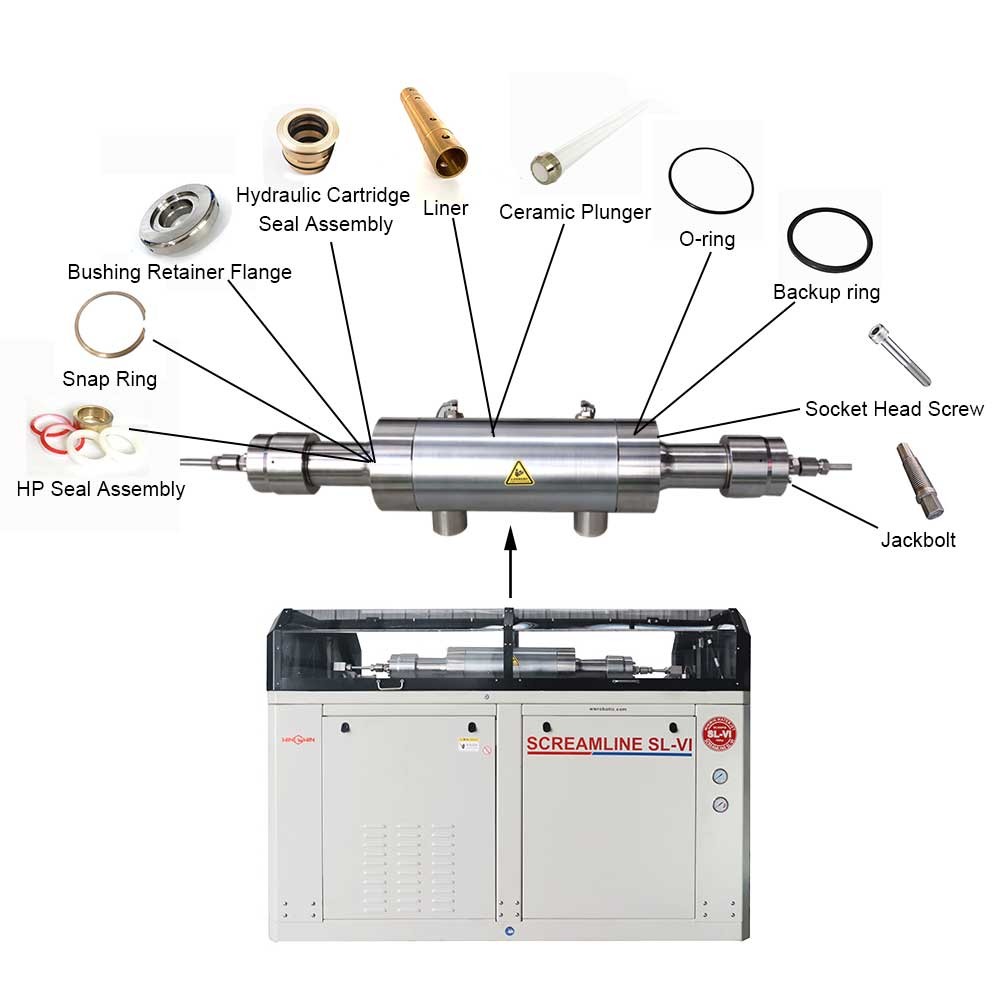

Waterjet spare parts are an important component of water jet cutting, as the intensifier pump is the core system of water jet cutting. The damage to waterjet spare parts can cause the water jetcutting system to shut down. Therefore, it is important to regularly replace waterjet spare parts.

How to maintain water je cutting machine

The water jet is used to cut and break the object. In the cutting function of the water jet, when the water jet contacts the object, its speed will change, but I don't know in what way. And for the water jet, how to maintain it?

When the pressure in the water jet reaches a certain height, the water will flow out of the nozzle of the water jet and shoot on the object at an ultra-high running speed, resulting in impact on it. However, when the impact occurs, it will also cause the sudden change of jet velocity, which will lead to the sudden change of internal pressure in the state of water droplets and the internal stress field of the material at the contact point, and destroy the object.

In other words, the water jet droplets of the water jet of the water knife interact with the object. When the droplets act on the surface of the object, the jet can remain flat only in the first stage, and free radial movement will occur once they contact with solid materials. Therefore, the speed of the water jet changes in an instant.

Since the water jet is a tool with very strong cutting ability, it can be used in the cutting of various materials. In addition to the important waterjet spare parts such as orifice and nozzle, the high-pressure intensifier is also an indispensable part of the water jet. In order to ensure the safety of water jet cutting process, the normal operation of intensifier is one of the conditions, and one of the measures to prevent problems is to pay attention to maintain waterjet spare parts.

The specific work to be done includes frequently checking whether the cooling device of the water knife high-pressure generator starts automatically to keep the cooling water temperature within the specified range; At the same time, the liquid condition should be observed frequently and the hydraulic oil should be supplemented in time according to the actual situation of the hoop bending machine. If the high-voltage generator is disturbed by dust, it will also be damaged.

Therefore, dust-proof devices must be set at all parts to keep it in good working condition. In addition, it is often necessary to check the oil filter signal light generated by water knife high pressure, so that its corresponding role can be played smoothly. In short, if there is no problem with the high-voltage generator, the failure probability of the water jet will be obviously controlled.

The waterjet technology was born in the United States in the early 1970s. It is proud that the founder of this technology is Chinese. However, before the 1990s, its applied technical knowledge was mastered by a few developed countries in Europe and America, and China could only spend a lot of money to introduce it from abroad. The vast majority of enterprises and researchers in research institutes can not experience the shock brought by this cold cutting process, and even don't know what water jet is.The nozzle of abrasive water jet cutting machine is one of the important waterjet spare parts in the cutting system. Its structure, working performance and service life directly affect the cutting quality and production cost of the workpiece.

Only by increasing the working pressure of water jet can it be widely used in large industrial sectors, which has become a consensus.After the advent of the water cutting machine of the American company, ultra-high pressure water jet cutting has always been a hot spot in the research and tracking of the water jet industry. While the water jet technology is developing towards high pressure, a noticeable new trend appeared in the international water jet field in the late 1970s. The direction was found from the medium of the water knife, that is, from the point of view of increasing the water jet pressure alone, it began to study how to improve and give full play to the potential of the water jet. There are pulse jet (water gun), high temperature jet, abrasive jet and oscillating jet. Compared with the ordinary continuous jet under the same pressure, this jet obviously greatly improves the operation efficiency.

WIN-WIN is a waterjet leader which has been researching in waterjet cutting industry for 20 years. We can provide you with the right waterjet cutting solutions and waterjet spare parts. We have many waterjet spare parts brands that you can choose for your waterjet intensifier pumps. And we can customize water jet cutting mahcines for you.

wwaterjet

wwaterjet