05147863 compression ring for 90000psi waterjet pump

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

There are several environmental benefits of using waterjets for cutting and cleaning materials. Here are some of the main benefits:

Reduced waste: Waterjets produce very little waste material compared to other cutting methods. This is because the cutting process is very precise, and there is no thermal distortion or burring around the cut edge. This can result in cost savings and reduce the environmental impact of waste disposal.

No hazardous chemicals: Waterjets use only water and abrasive material (if necessary) for cutting and cleaning, making them an environmentally friendly option compared to other cutting methods that may use chemicals or produce harmful fumes.

Energy efficient: Waterjets are generally considered to be energy-efficient compared to other cutting methods. This is because waterjets use only the energy required to generate the high-pressure water stream, whereas other cutting methods may require additional energy to power cutting tools or produce heat.

Recyclable abrasive material: Some waterjet machines use abrasive material for cutting, which can be recycled and reused multiple times. This reduces the amount of waste generated and can result in cost savings.

Reduced carbon footprint: Using waterjets for cutting and cleaning can help reduce the carbon footprint of manufacturing and industrial processes. By eliminating the use of hazardous chemicals and reducing waste, waterjets can help companies achieve their sustainability goals and reduce their environmental impact.

Overall, the environmental benefits of using waterjets make them an attractive option for businesses looking to reduce their environmental impact and prioritize sustainability. The lack of hazardouschemicals, reduced waste, and energy efficiency of waterjets can result in cost savings and help companies meet their sustainability goals. Additionally, the ability to recycle abrasive material can further reduce the environmental impact of waterjet cutting.

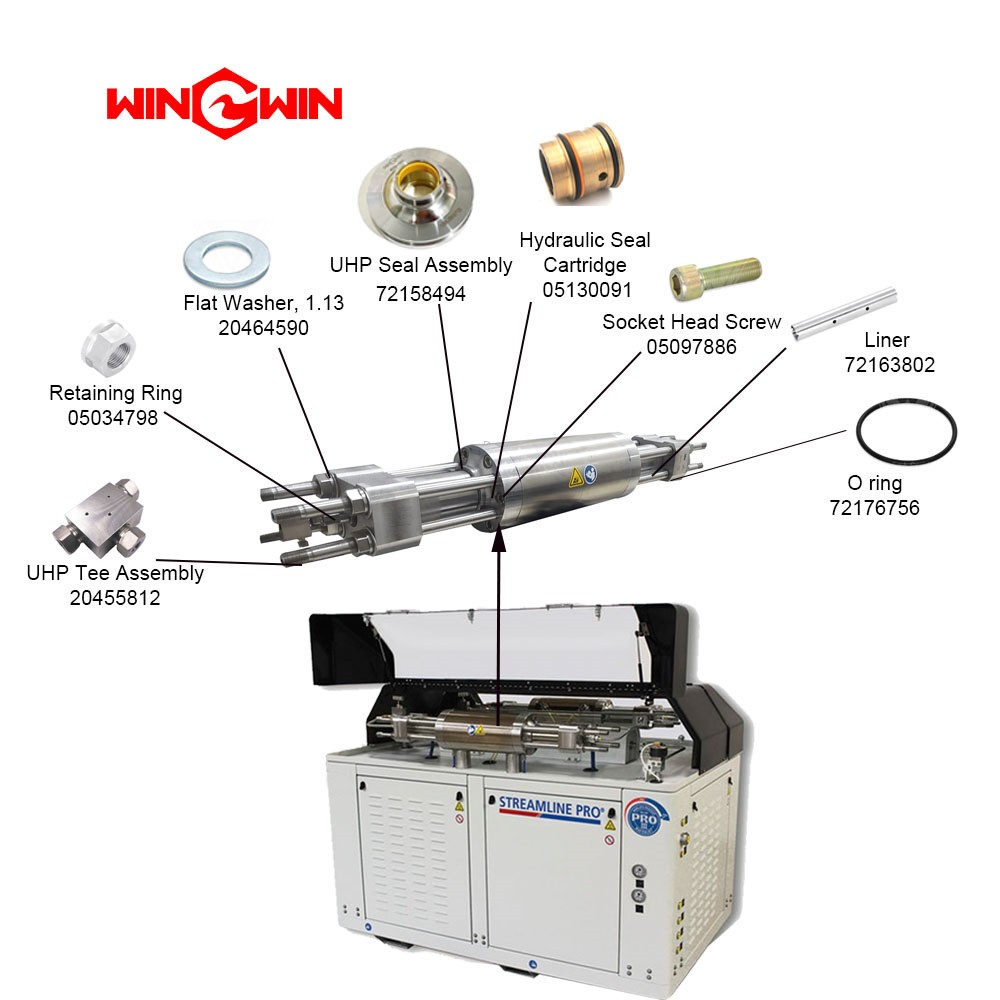

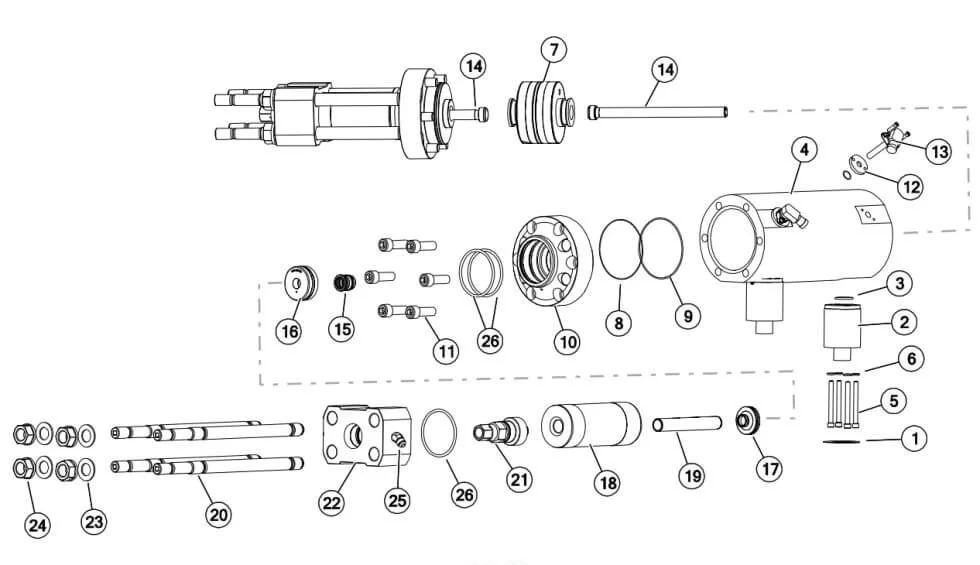

| Item | Part Number | Description | Item | Part Number | Description |

| 1 | 5146592 | Gasket, Topworks Support | 14 | 72162253 | Plunger |

| 2 | 20476377 | Support, Topworks | 15 | 5130091 | Hydraulic Seal Cartridge |

| 3 | 10118206 | O-Ring, 1.31×1.56× .13 | 16 | 72175989 | Bushing Retainer Flange |

| 4 | 5144514 | Hydraulic Cylinder | 17 | 72158494 | UHP Seal Assembly |

| 5 | 5098991 | Socket Head Screw, 3/8-16×3-3/4 | 18 | 72166738 | UHP Cylinder |

| 6 | 95688743 | Lock Washer, .38 | 19 | 72163802 | Liner |

| 7 | 72101190 | Piston Assembly | 20 | 20474325 | Stud, 1-1/8-12×18.31 |

| 8 | 10074771 | O-Ring, 5.25×5.50× .13 | 21 | 72170157 | Sealing Head Assembly |

| 9 | 5120092 | Backup Ring, 5.25×5.50× .13 | 22 | 72178493 | Flange Assembly |

| 10 | 72175997 | Hydraulic Cylinder Head | 23 | 20464590 | Flat Washer, 1.13 |

| 11 | 5097886 | Socket Head Screw, 3/4-16×2-1/4 | 24 | 20461761 | Hex Nut, 1-1/8-12 |

| 12 | 5144183 | Spacer Assembly, Proximity Switch | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 |

| 5144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | |

| 13 | 72141569 | Kit, Proximity Switch | 95119012 | Socket Head Screw, 1/4-20×1 | |

| 72134224 | Proximity Switch |

wwaterjet

wwaterjet