Characteristics of water jet cutting equipment

Now is the era of high technology. In the past, the production of products required manual operation, but with the discovery of the times, many intelligent products have gradually replaced manual operation, saved a lot of employment costs, and improved work efficiency. Therefore, the use of mechanical equipment is becoming more and more widely. The following mainly introduces the processing characteristics of water jet cutting equipment and waterjet spare parts.

Machining characteristics of robot water jet cutting equipment:

1. Various complex water jet cutting patterns are adopted; It can make corresponding cutting, including various shapes, angles or slopes, and can cut any modeling pattern;

2. It belongs to cold cutting and does not produce thermal deformation or thermal effect; Higher cutting accuracy;

3. It is a means of processing some composite materials, fragile porcelain materials and complex materials;

4. After water jet cutting, the incision is smooth without slag, and there is no need for secondary processing such as edge grinding; The processing time is shortened, which improves the production efficiency and reduces the cost;

5. It can complete drilling, cutting and other processing procedures at one time;

6. Fast cost recovery;

7. High degree of automation;

8. Can work continuously for 24 hours;

9. Water jet cutting does not produce cracks. It can cut materials with narrow gaps. The larger the diameter of the inner hole of the sand nozzle, the larger the notch;

10. The water column of water jet cutting is small, so there is no need to worry that the cutting water will wet the product with high quality waterjet spare parts.

Using water jet cutting equipment is a good choice.Of course, if you use the wrong method, it will not work. If you want to know the correct method of use, you can log in to the official website to check, because there are many models of water jet cutting equipment, so you should consider what model to choose when buying, Only suitable models can be suitable for themselves. And how you can maintain your waterjet spare parts

The advantages of water jet cutting are not only obvious to all, but also recognized by more and more enterprises. As a kind of cold cutting process, it has many advantages that other cutting technologies can't do. Because of this, you can do many things with water jet cutting an high quality waterjet spare parts, one of which is metal processing.

Since water jet cutting has no restriction on the cutting direction, it can complete various cutting shapes, and can be flexibly adjusted according to the material and processing requirements of the work piece, so as to improve the production efficiency by using high quality waterjet spare parts. In addition, when water jet cutting processing metal, it does not need cumbersome process, and the work piece can be completed at one time without secondary processing, which can provide great convenience for users. Water jet cutting is best choice to cut hard metal.

High pressure tube of water jet

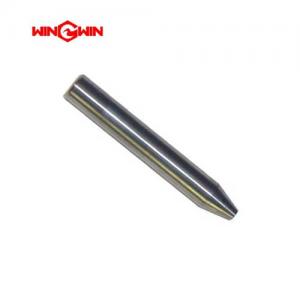

The intensifier pump of water jet plays a vital role in cutting quality, which determines whether the water is strong or not and stable. After the intensifier pump generates water pressure, the waterjet spare part HP tube transmits the water to the cutting head body. In addition to transmitting high-pressure water, waterjet spare part HP tube also helps the cutting head move freely. It is worth noting that the most common form of high-pressure tube is special stainless steel pipe. Pipes have different specifications and are used for different purposes.

1 / 4-inch waterjet spare part HP tube - because this specification of steel pipe has windability, this kind of pipe is often used as the pipe of sports equipment. It is not used for long-distance transmission of high-pressure water (such as from the pump to the base of sports equipment). It bends very easily. In fact, this kind of pipe can also be coiled (in case of long-distance transportation, the coil can provide greater windability and be used for robot arm movement).

3 / 8-inch waterjet spare part HP tube - It can be bent. In fact, in general, it is not used as a pipe for sports equipment.

9 / 16 waterjet spare part HP tube - commonly used for long-distance transportation of high-pressure water. Its large inner diameter can reduce pressure loss. This kind of pipe is very useful when theintensifier pump needs to use a large pump (the more high-pressure water needs to be transmitted, the greater the potential pressure loss). This tube cannot be bent. Joints (tees, elbows, etc.) are required at corners.

In fact, high-pressure seal failure will generate heat due to squeezing out water flow through small holes (friction), while low-pressure leakage will not produce obvious heat.

wwaterjet

wwaterjet