Overview of water jet cutting platform

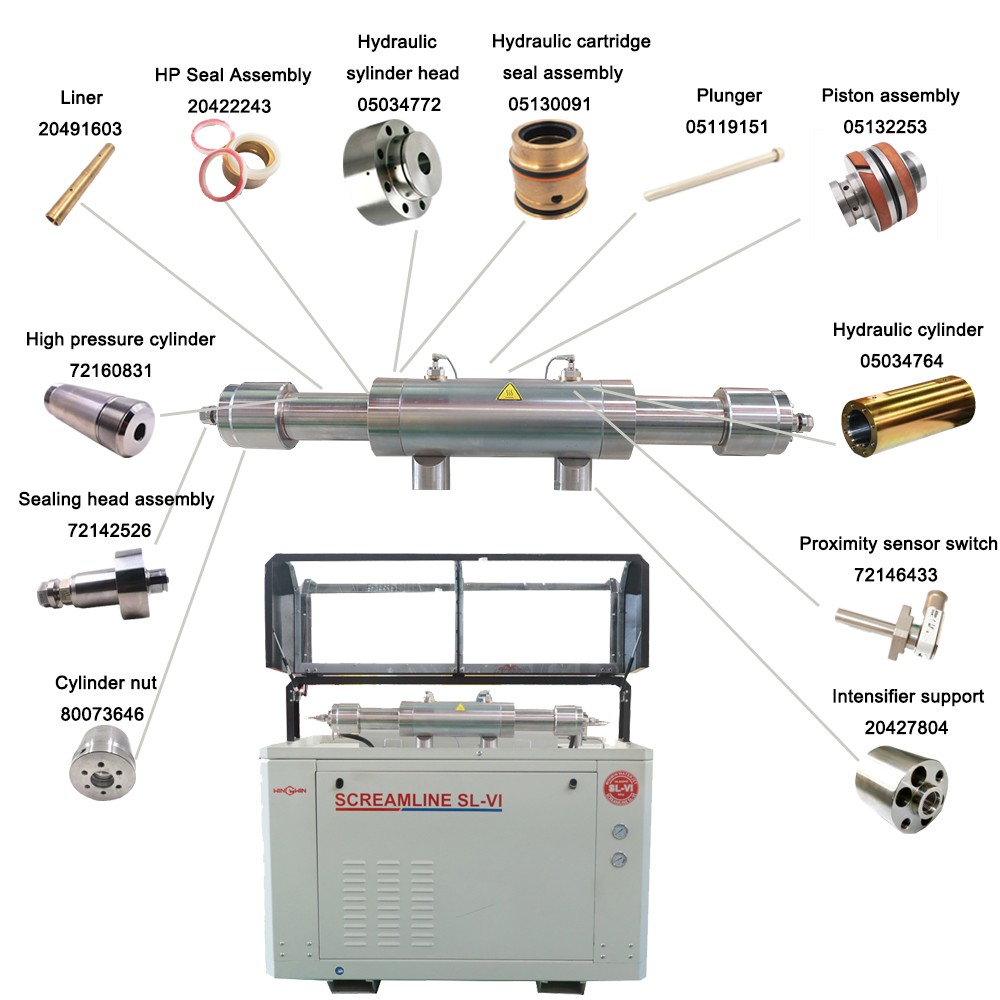

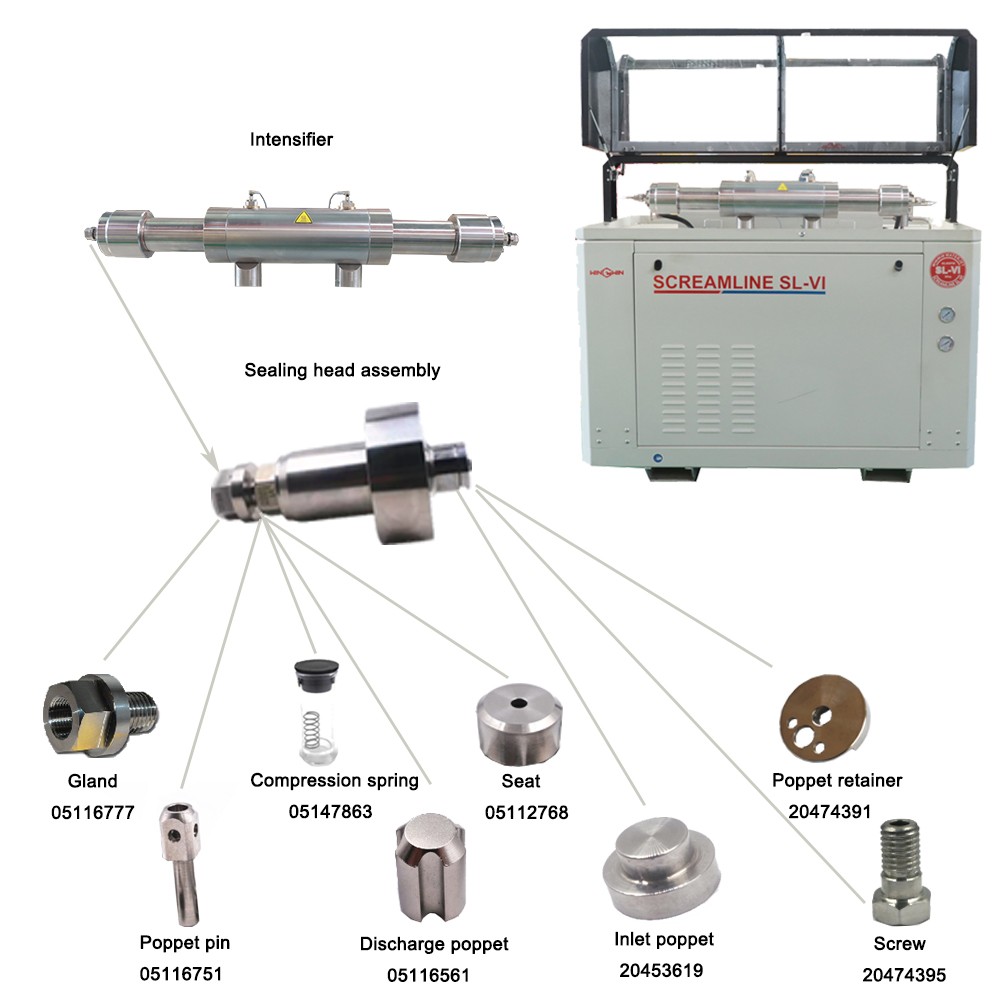

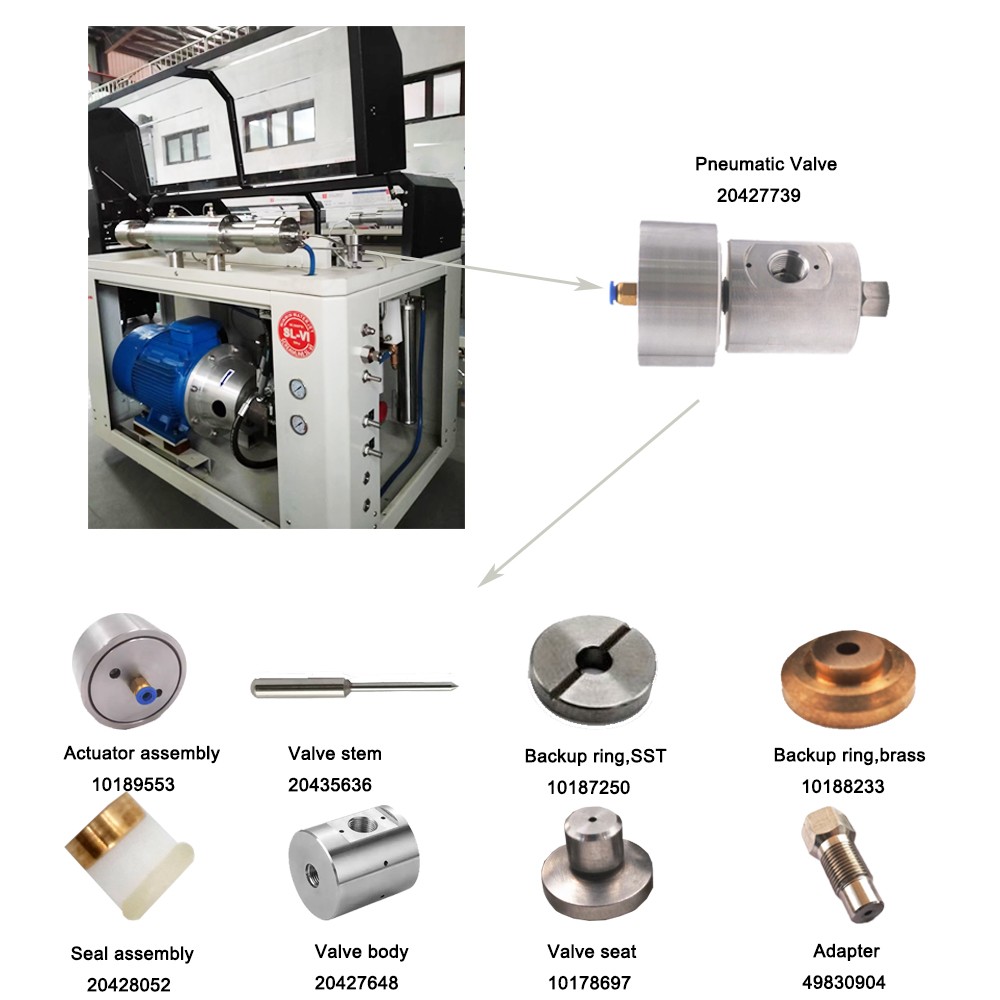

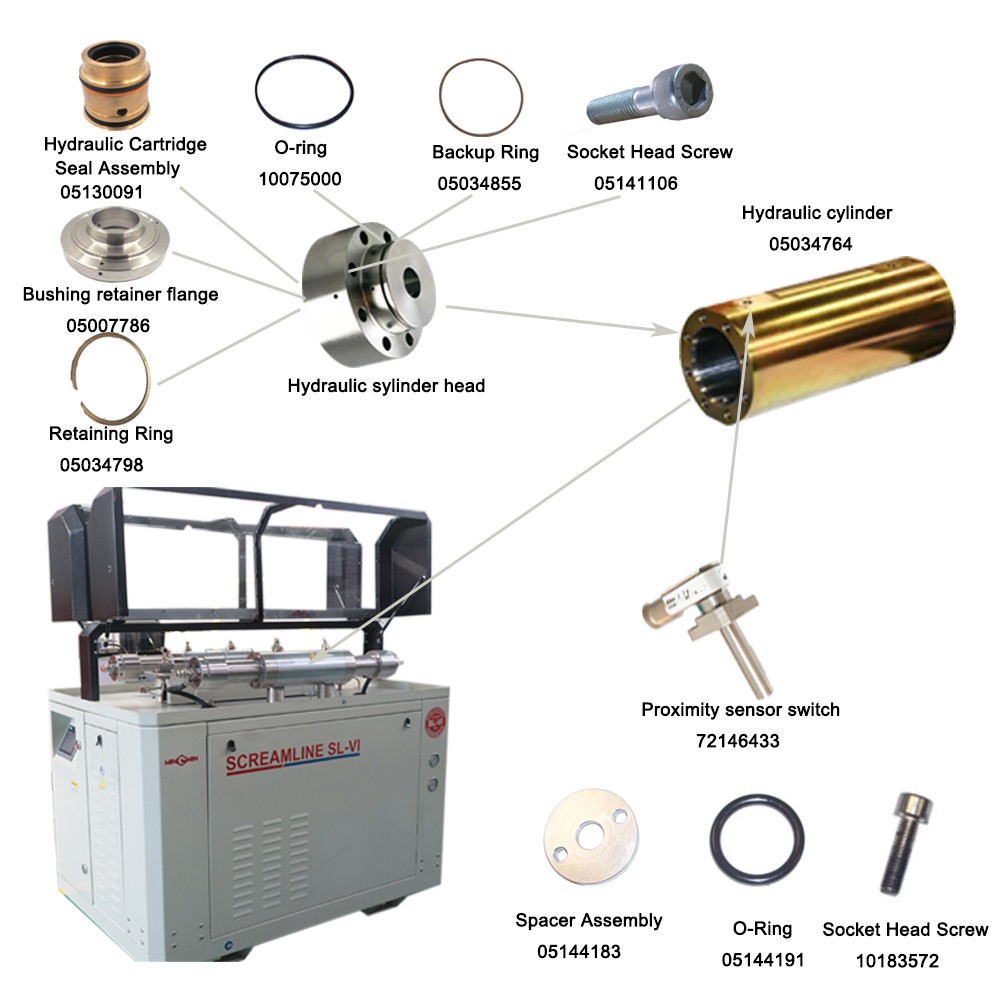

Water jet NC cutting platform is an extremely important part of water jet cutting machine. The transmission parts of x-axis, Y-axis and z-axis are mainly composed of guide rail platform, water jet spare part linear guide rail, bearing seat, ball screw, support nut and slider. The water tank part is composed of platform frame, water tank, grid strip and grid angle steel

The cutting part is composed of water jet spare part HP tube, water switch, water jet spare part cutter head and sand storage container. The lubrication part is composed of piston pump, oil filter and throttling distributor. The NC driving part is composed of x-axis Y-axis servo motor Z-axis stepping motor, synchronous wheel, synchronous belt, etc.

The water jet spare part cutting head is cut along the x-axis direction through the connection of the connecting frame, the water jet spare part cutting head is adjusted up and down along the z-axis direction through the connection of the connecting frame, and the x-axis beam drives the water cutter head to cut along the y-axis direction through the connection of the side supports at both ends (gantry type).

If the core of the high-pressure intensifier with high quality of water jet spare part is to produce high pressure water, the core of the NC cutting platform is to use ultra-high pressure water to cut various complex and changeable shapes and graphics under the control of the computer. Due to the use of mechanical structures such as linear guide rail, ball screw and servo motor, the accuracy of cutting various complex graphics is ensured through the control of industrial computer. The CNC cutting platform produced by our company, after understanding the safety warning of the water jet platform and having a good practice in its operation, the operator can not only realize the XY axis plane processing, but also realize automatic or manual adjustment in the Z axis direction, so as to meet the process requirements of cutting various materials to the greatest extent.

Types of water jet cutting machine

CNC cutting platform has two mechanical structures: cantilever type and gantry type. Cantilever structure, small volume, simple structure and short stroke of x-axis and y-axis. It is most suitable for processing all kinds of complex small parts. Compared with the cantilever structure, the gantry structure has large volume and relatively complex structure. The CNC cutting platform produced by waterjet with good water jet spare parts has various specifications and models, which has become a system. In order to meet the needs of the market, large, super large and vertical CNC cutting platforms have been produced, or customized according to the needs of customers.

Compared with other cutting tools, water jet cutting machine with good water jet spare parts has the advantages that can not be replaced by other cutting tools. Common cases include: large-scale ceramic murals, hall floor mosaic, ceramic screen, special-shaped countertop of cabinet and bathroom, stone furniture, etc. It is very suitable for decoration material processing industry. Taking the ground mosaic as an example, the use of NC water jet machining can not only save time and labor cost, but also reduce the occupied space of equipment; Moreover, it can save 40% of the material cost, reuse a large number of corner waste and turn waste into treasure by using water jet spare parts.

Abrasive waterjet cutting machine can cut any ceramic without changing tools. Its own starting hole can drill the material. It can make holes in most materials without special treatment. For specific brittle materials. Sanding water knife cutting machine will not cause thermal energy or surface deformation. Therefore, the material can maintain its original appearance and strength. In the ceramic processing industry, the traditional cutting method is usually saw blade cutting, which can only cut straight lines.

When it is necessary to cut curves, the template meeting the size requirements shall be made first, which shall be realized by manual grinding after preliminary cutting.Waterjet cutting has low flexibility, high noise, much dust and low efficiency. The advantages of water jet cutting ceramics are obvious: firstly, the incision is flat, the cutting quality is high, and the phenomenon of "edge explosion" will not be formed on the upper edge of the incision after cutting; Secondly, the cutting precision is high, the cutting precision reaches 0.1mm, and the seam is uniform. At the same time, the cutting efficiency is fast, the product consistency and interchangeability are good, the automatic nesting function can be realized, the working environment can be improved, and the impact of dust and noise on operators can be reduced.

As the main processing machine in ceramic and stone industry, water jet with good water jet spare parts is widely used. Common cases include: large-scale ceramic murals, hall floor mosaic, ceramic screen, special-shaped countertop of cabinet and bathroom, stone furniture, etc.

Win Win Waterjet

Win Win Waterjet