3020 AC 5axis with Lifting function Water Cutting Machine

Abrasive waterjet cutting machines are highly versatile and powerful tools used in various industries to cut a wide range of materials, including metals, composites, glass, ceramics, and stone. These machines utilize a high-pressure jet of water mixed with abrasive particles to cut through hard materials with precision and minimal thermal impact.

Abrasive waterjet cutting machines are powerful and versatile tools that offer precision and efficiency for cutting a wide range of materials. Proper maintenance and regular inspections are essential to ensure optimal performance and longevity of the machine. By following best practices and addressing issues promptly, operators can maximize the benefits of their abrasive waterjet cutting system.

Features

A. Type of gantry

The overall structure of the gantry, both ends of the cutting arm are supported, and it is not easy to tilt even if it is used for.

For a long time, it is not easy to cause cutting errors, and the cutting is more stable. The folding dust-proof cloth is canceled, and a new all-stainless steel integrated protection structure is adopted, which has good dustproof and waterproof effect and does not need to be replaced.

B. High quality cutting head

Waterjet cutting head made of aluminum, light weight but high hardness, lightened gantry operating load, relatively fast running speed, higher cutting efficiency.

C. Linear guide fully immersed in oil

WW3020A adopts thick linear guides and large screw balls. X, Y axis adopts oil-immersed screw guide rail lubrication method, which is better than traditional synchronization lubrication effect, better dustproof effect and longer service life.

D. Absolute encoder system

High-end bearing motor configuration, no need for additional stopper, perfect combination with CNC system to realize precise positioning of cutting head.

E. Manual abrasive dosing controller

Unique sand control valve design, simple structure, manual control of abrasive feeding speed, no wearing parts, maintenance-free and anti-reflux (water return) function.

F. Built-in stainless steel bathtub

The table is made of all stainless steel, rust-proof, corrosion-resistant, shiny as new for 10 years

Rated Powe | 30KW/40HP | Max. operating pressure | Max. operating pressure |

Continuous working pressur | 320MPa-380MPa | Max. discharging rate | 3.8L/min |

Orifice diamete | 0.33mm or others | Nozzle diameter | 1.02mm or other |

Tank volume | 150L | Size | 1800mm*1100mm*1300mm |

Weight | 800kg |

JET50 Waterjet pump ————— Features

A. Beautiful appearance and reasonable design

The appearance is more exquisite and beautiful, small and exquisite, the main parts of the intensifier and accumulator are grouped together and installed above the center of the pump, with a transparent acrylic cover, which is convenient to observe the working status at any time.

B. High performance and standard design

Universal structure design, international standard spare parts. High versatility of accessories, customers can purchase the corresponding parts in any waterjet machine market.

C. Newly designed accumulator

Accumulator of new design, integrally forged, without rubber seals, maintenance-free.

D. Double oil filtration system

Double filtration devices are placed at the oil inlet and oil return port to ensure that the oil path is clean, smooth and not blocked, and extend the service life of the waterjet pump.

| WEIHONG WATERJET CNC CONTROL SYSTEM | |

| Brand | WEIHONG® (ENGLISH) |

| Display | Industrial grade display |

| Language | English/Chinese//Others |

| System version | Win10 |

| Format | CAD/G/DXF/ENG/PLT, etc. |

| System Function | AC-5Axis/AB-3Axis |

CNC Control System————— Features

A.Industrial grade screen, special waterjet software, easy to operate.

B.Absolute encoder system, memory function after power failure.

C.Simulation operation, pause and start at any time, continue cutting from any position and point.

D. A more user-friendly and intelligent function has been added, namely the setting and recall function.

Specification for Abrasive Tank | |

| Wall Thickness | 4.5mm (Explosion proof) |

| Air Pressure | 0.2MPa-1MPa |

| Volume | 200kg |

Abrasive Feed Tank ————— Features

A. The automatic abrasive dispensing system continuously supplies abrasive to the abrasive regulator tank on the cutting head next to the large abrasive tank.

B. Without any electrical components, it is maintenance-free, zero defect.

C. Reasonable design enables this large capacity abrasive tank to cut 8-10 hours without interruption.

D. Large diameter flange at the bottom, easy to remove debris.

Specification for cooling:

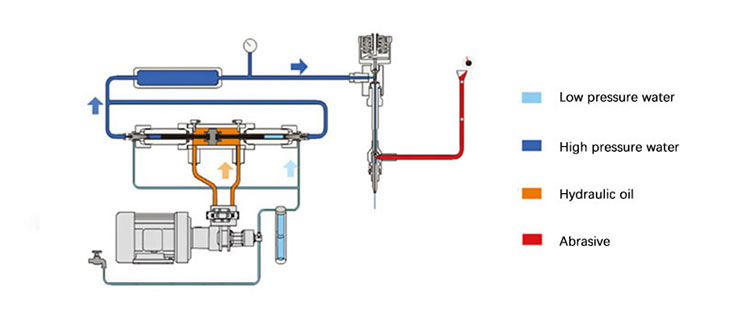

As you know, the pump is driven by hydraulic oil for intensifier work.

Excessive temperature of hydraulic oil will seriously affect the service life of metal parts and sealing parts of the hydraulic part of the intensifier pump.

Refrigerator cooling with super cooling effect, closed internal circulation system, more environmental health, beautiful appearance, reliable performance.

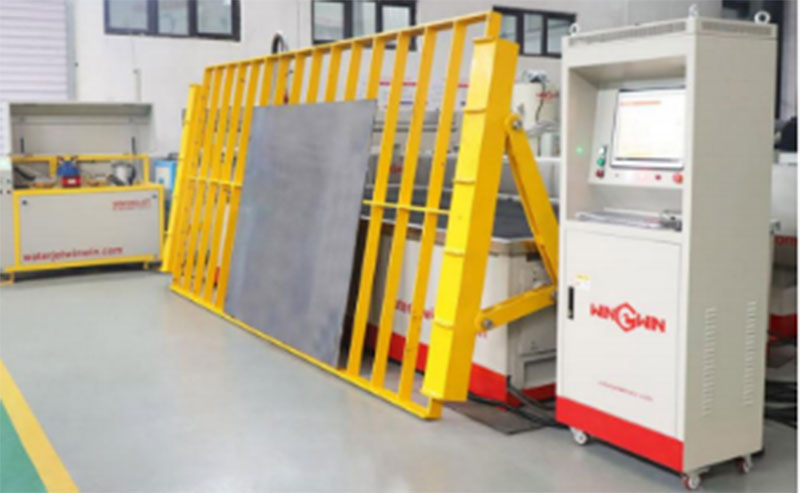

Loading and unloading device:

The functions of the waterjet cutting table loading and unloading tilting device include loading and unloading, which is very necessary for users who cut large and heavy materials.

This function can realize automated loading and unloading, reducing the operator's labor and time,and is very safe, improving cutting efficiency and accuracy

wwaterjet

wwaterjet