Techni Waterjet 500-19-0053 Oil filter moisture absorption 24 Micron

The TECHNI Waterjet 500-19-0053 Oil Filter Moisture Absorption 24 Micron is a specialized filter designed for use in TECHNI waterjet cutting systems. This filter serves the dual purpose of filtering out particulates as small as 24 microns and absorbing moisture from the oil, which is crucial for maintaining the efficiency and longevity of the hydraulic system in the waterjet cutting machine.

Key Aspects of the TECHNI Waterjet 500-19-0053 Oil Filter Moisture Absorption 24 Micron

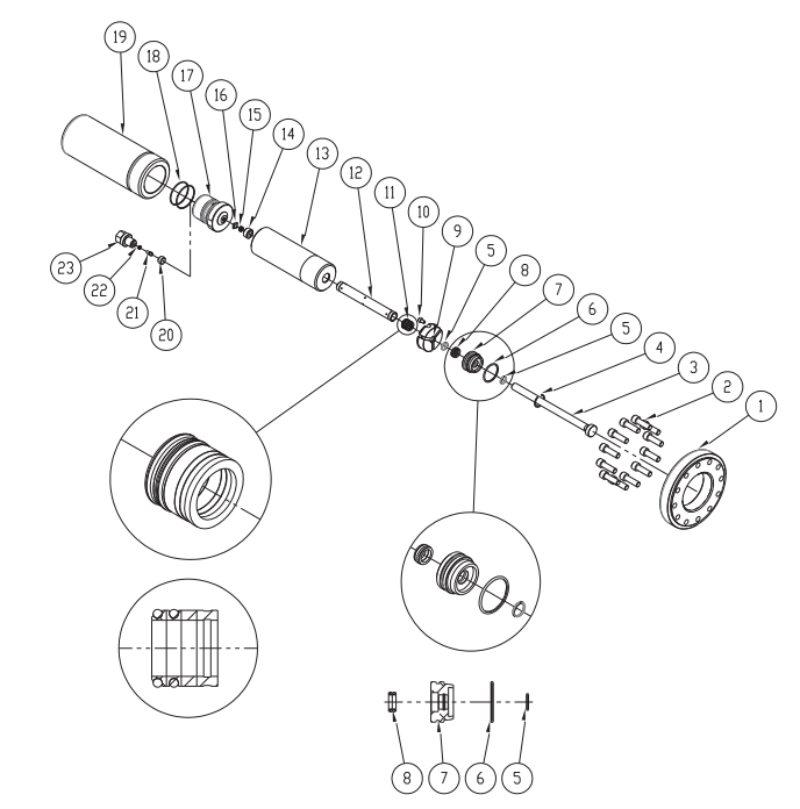

Material:

High-Quality Filtration Media: The filter media is engineered to capture fine particles and absorb moisture effectively, ensuring that the hydraulic oil remains clean and dry.

Durable Construction: Built to withstand the demands of high-pressure hydraulic systems, providing long-lasting performance.

Design:

Micron Rating: The 24-micron rating indicates the filter’s ability to capture particles as small as 24 microns, ensuring that contaminants are effectively removed from the oil.

Moisture Absorption: Specially designed to absorb moisture from the oil, preventing water contamination which can lead to corrosion, reduced lubrication, and system inefficiencies.

Function:

Contaminant and Moisture Removal: Ensures that the hydraulic oil remains free from particulates and moisture, which is essential for the reliable operation of the hydraulic components in the waterjet system.

System Protection: Protects the hydraulic pump, valves, and other components from damage due to contaminants and moisture, thereby extending their lifespan and reducing maintenance costs.

Maintenance Tips for Oil Filter Moisture Absorption

Regular Inspection:

Periodically inspect the filter for signs of clogging, saturation, or damage. Regular inspections help identify when the filter needs replacement to maintain optimal system performance.

Replacement:

Replace the filter at recommended intervals or when it shows signs of significant contamination or moisture absorption. Using a worn or saturated filter can compromise the hydraulic system’s performance.

Proper Installation:

Ensure the filter is correctly installed according to the manufacturer’s guidelines. Incorrect installation can lead to inadequate filtration and potential system damage.

Troubleshooting Common Issues

Clogging:

If the filter becomes clogged, it can restrict oil flow and reduce system efficiency. Inspect and replace the filter as needed to maintain proper flow.

Moisture Contamination:

If there is evidence of moisture in the hydraulic oil, the filter may be saturated and in need of replacement. Regular monitoring of oil quality can help prevent this issue.

Leaks or Damage:

Inspect the filter housing and connections for leaks or damage. Ensure that the filter is properly seated and the housing is securely closed.

If you are interesting in TECHNI Waterjet,Contact us any time.

wwaterjet

wwaterjet