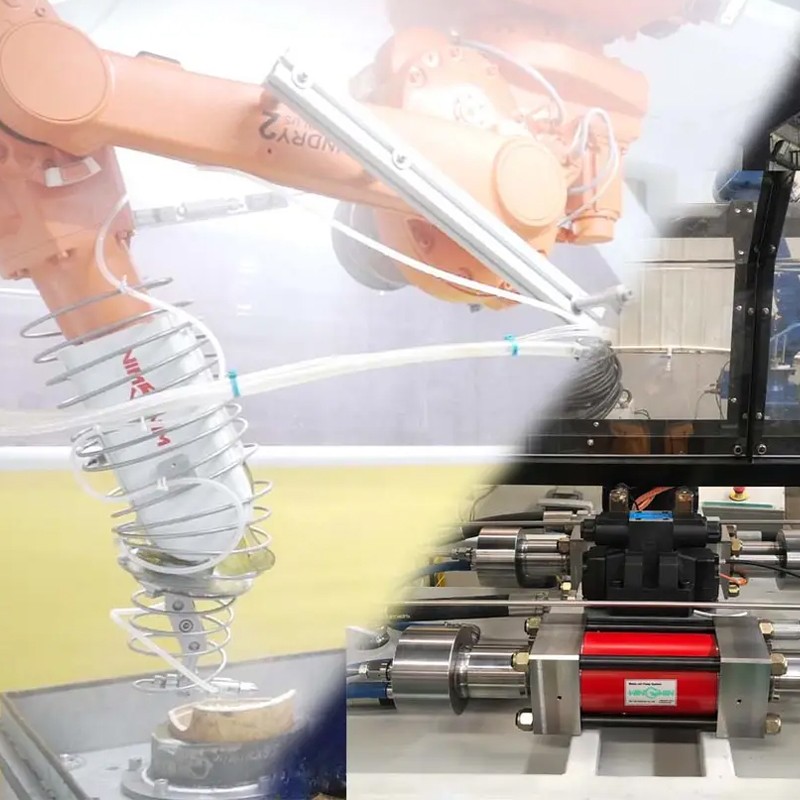

Robot Waterjet Helmet Cutting Machine

Are you looking for Robot Waterjet Helmet Cutting Machine?

WINWIN provide customized solution for you.

There are various types of helmets that Robot Waterjet Helmet Cutting Machine can cut, including:

Safety Helmets:

Used in construction, mining, manufacturing, and other industrial settings to protect workers from falling objects, impact, and other hazards.

Examples include hard hats, bump caps, and specialized helmets for specific applications.

Motorcycle Helmets:

Worn by motorcycle, scooter, and moped riders to protect the head in the event of a crash or impact.

Types include full-face, open-face, and modular helmets.

Bicycle Helmets:

Designed to protect the head of cyclists, both recreational and competitive.

Typically lightweight and ventilated to provide comfort and safety during cycling activities.

Sports Helmets:

Used in various sports, such as American football, ice hockey, baseball, lacrosse, and climbing, to protect athletes from head injuries.

These helmets are often designed with specific features and materials to suit the demands of the sport.

Military and Tactical Helmets:

Used by military, law enforcement, and special operations personnel to protect against ballistic threats, shrapnel, and other combat-related hazards.

Examples include combat helmets, tactical helmets, and ballistic helmets.

Equestrian Helmets:

Worn by horse riders to protect the head from falls and impacts during equestrian activities, such as riding, jumping, and polo.

Welding Helmets:

Used by welders to protect their eyes and face from the intense light and sparks generated during welding operations.

These helmets are used in a wide range of industries, including:

Construction

Manufacturing

Transportation (automotive, aviation, maritime)

Sports and recreation

Military and law enforcement

Mining and extraction

Healthcare and emergency services

Welding and metalworking

Using Robot Waterjet Helmet Cutting Machine offers several benefits:

Precision Cutting:

Robotic waterjet cutting systems provide highly precise and accurate cuts, which is crucial for producing high-quality helmet components.

The computerized control of the waterjet cutting process ensures consistent and repeatable cuts, reducing waste and improving the fit and finish of the helmet.

Versatility:

Waterjet cutting is a versatile technique that can handle a wide range of materials used in helmet manufacturing, such as plastics, composites, and specialty alloys.

Robotic systems can be programmed to cut complex helmet designs and shapes, allowing for greater design flexibility and customization.

Increased Productivity:

Robotic waterjet cutting equipment can operate continuously with minimal downtime, improving overall production efficiency.

The automated cutting process reduces the need for manual labor, freeing up workers to focus on other tasks.

Improved Safety:

The waterjet cutting process is inherently safer than traditional mechanical cutting methods, as it does not generate heat or produce harmful debris.

The robotic system's precise control and enclosed cutting area further enhance safety by minimizing the risk of operator injuries.

Reduced Material Waste:

Robotic waterjet cutting systems can optimize the material usage by nesting multiple helmet components within a single workpiece, minimizing material waste.

The precise cutting reduces the need for extensive post-processing, such as trimming or grinding, further reducing waste.

Consistent Quality:

The automated and controlled nature of robotic waterjet cutting helps to ensure consistent quality in the helmet components, reducing the risk of defects or variations.

This can lead to improved product reliability and customer satisfaction.

Scalability:

Robotic waterjet cutting systems can be easily scaled to accommodate increased production demands, making them well-suited for high-volume helmet manufacturing.

By using Robot Waterjet Helmet Cutting Machine, helmet manufacturers can improve their production efficiency, reduce costs, enhance product quality, and meet the growing demand for innovative and high-performance helmet designs.

Contact us to customize the suitable solution for you.

wwaterjet

wwaterjet