Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

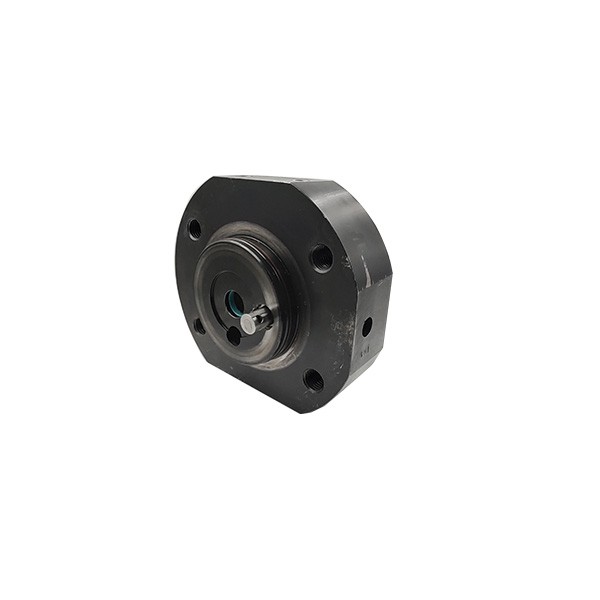

HT022008/172 flange for BFT waterjet

Water quality is a critical factor in the proper operation of a waterjet cutting system. Poor water quality can lead to issues with the system, including damage to the intensifier pump, clogging of the cutting head, and reduced cutting performance. Here are some common signs of water quality issues:

Reduced cutting performance: Poor water quality can result in reduced cutting performance, including slower cutting speeds and reduced accuracy. If you notice a significant decrease in the cutting performance of the system, it may be a sign that the water quality is poor.

Clogging of the cutting head: Poor water quality can result in clogging of the cutting head, which can result in reduced cutting performance or even damage to the system. If you notice that the cutting head is clogged or not performing properly, it may be a sign that the water quality is poor.

Corrosion: Poor water quality can result in corrosion of the components of the waterjet cutting system, including the intensifier pump, hoses, and fittings. If you notice signs of corrosion, such as rust or pitting, it may be a sign that the water quality is poor.

Mineral buildup: Poor water quality can result in the buildup of minerals, such as calcium, in the waterjet cutting system. This can lead to clogging of the system and reduced performance. If you notice mineral buildup in the system, it may be a sign that the water quality is poor.

Unusual odors or colors: Poor water quality can sometimes result in unusual odors or colors in the water. For example, the water may have a strong odor or a brownish color. If you notice any unusual odors or colors in the water, it may be a sign that the water quality is poor.

If you notice any of these signs, it is important to take steps to address the water quality issues as soon as possible. This can include using a water treatment system to remove impurities and contaminants from the water, changing the filters in the waterjet cutting system more frequently, or using a different source of water for the system. Working with an experienced and knowledgeable technician can help identify the cause of the water quality issues and recommend the appropriate course of action to address them. Regular monitoring of the water quality and taking proactive steps to address any issues can help prevent damage to the waterjet cutting system and ensure that it is operating at peak performance.

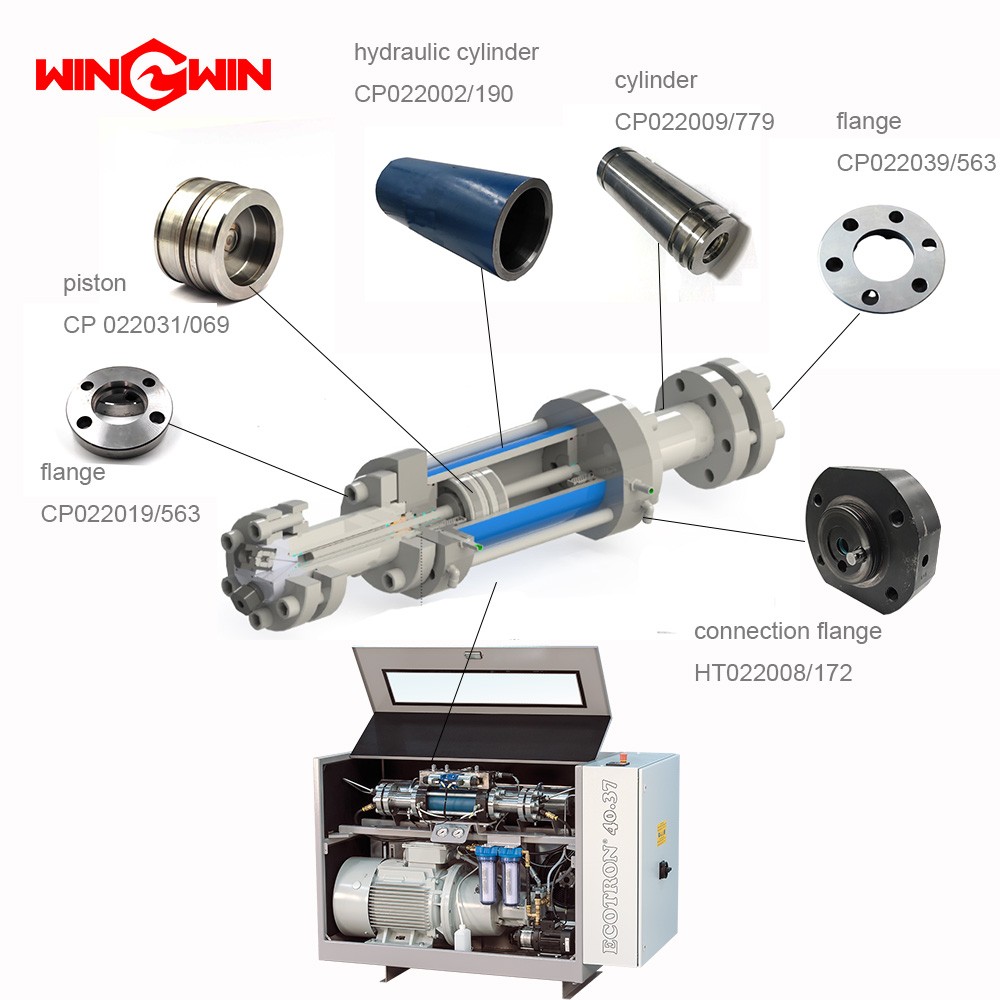

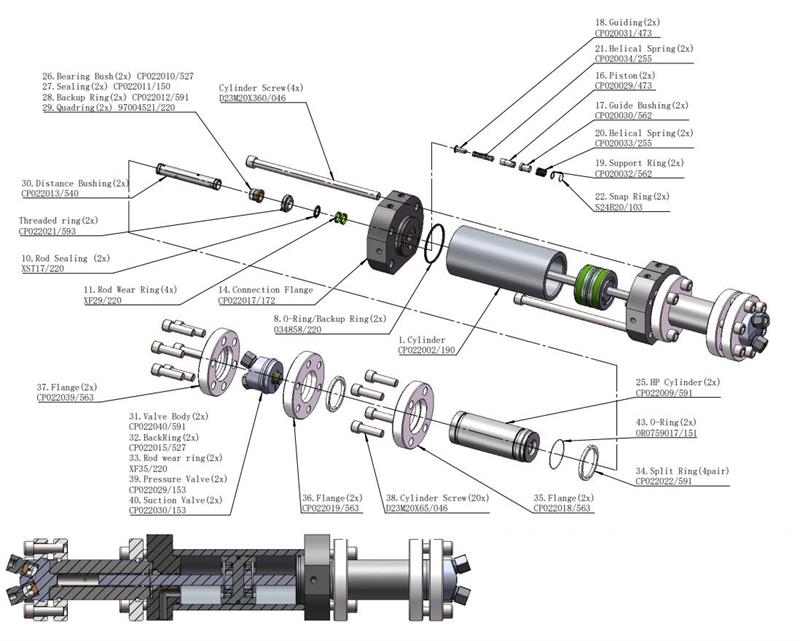

| CP022002/190 | Cylinder |

| 1200402 | piston complete |

| XK121/220 | Piston sealing |

| XF56/220 | Wear ring |

| CP022066/220 | Plunger complete |

| CP022057/075 | Clamp ring |

| HT022044/103 | Retaining ring |

| 034858/220 | O-ring backring 97 |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XF29/220 | Rod wear ring 22x27x5,6 mm |

| D23M20360/046 | Cylinder head screw |

| CP022017/172 | connection flange |

| CP022016/172 | connection flange |

| CP022021/593 | Thread ring |

| HT022004/473 | Piston |

| CP020030/562 | Bushing |

| CP020031/473 | Guiding |

| CP020032/562 | Supporting ring |

| CP020033/255 | helical spring |

| CP020034/255 | helical spring |

| CP020034/255 | Helical spring |

| S24B20/103 | Snap ring |

| xn5/220 | initiator |

| XST9/220 | PLUG |

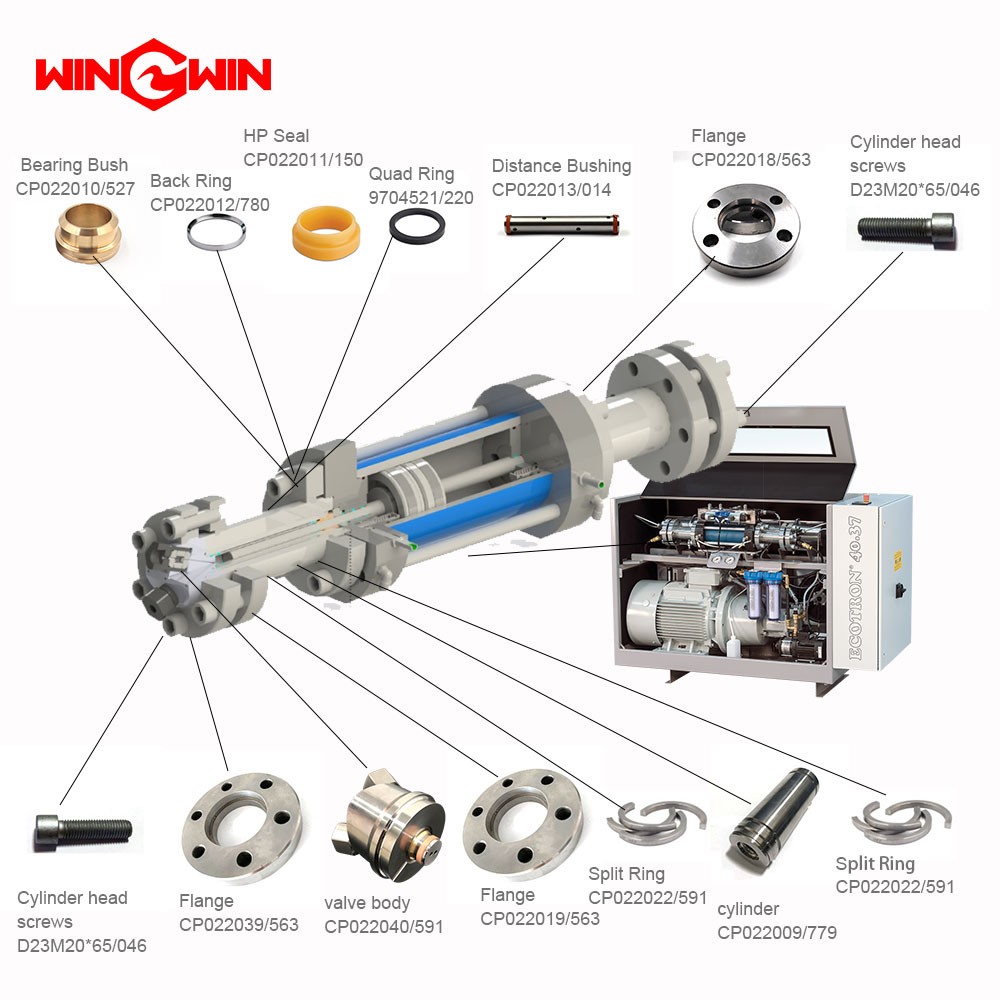

| CP022009/779 | High pressure cylinder |

| CP022010/527 | Bearing bush |

| CP022011/150 | Sealing |

| CP022012/780 | Back ring |

| 9704521/220 | Quadring |

| CP022013/014 | Distance bushing |

| CP022040/591 | Valve body |

| CP022015/527 | Back ring |

| XF35/220 | Rod wear ring |

| CP022022/591 | SPLIT RING |

| CP022018/563 | Flange |

| CP022019/563 | Flange |

| CP022039/563 | Flange |

| D23M20*65/046 | Cylinder head screw |

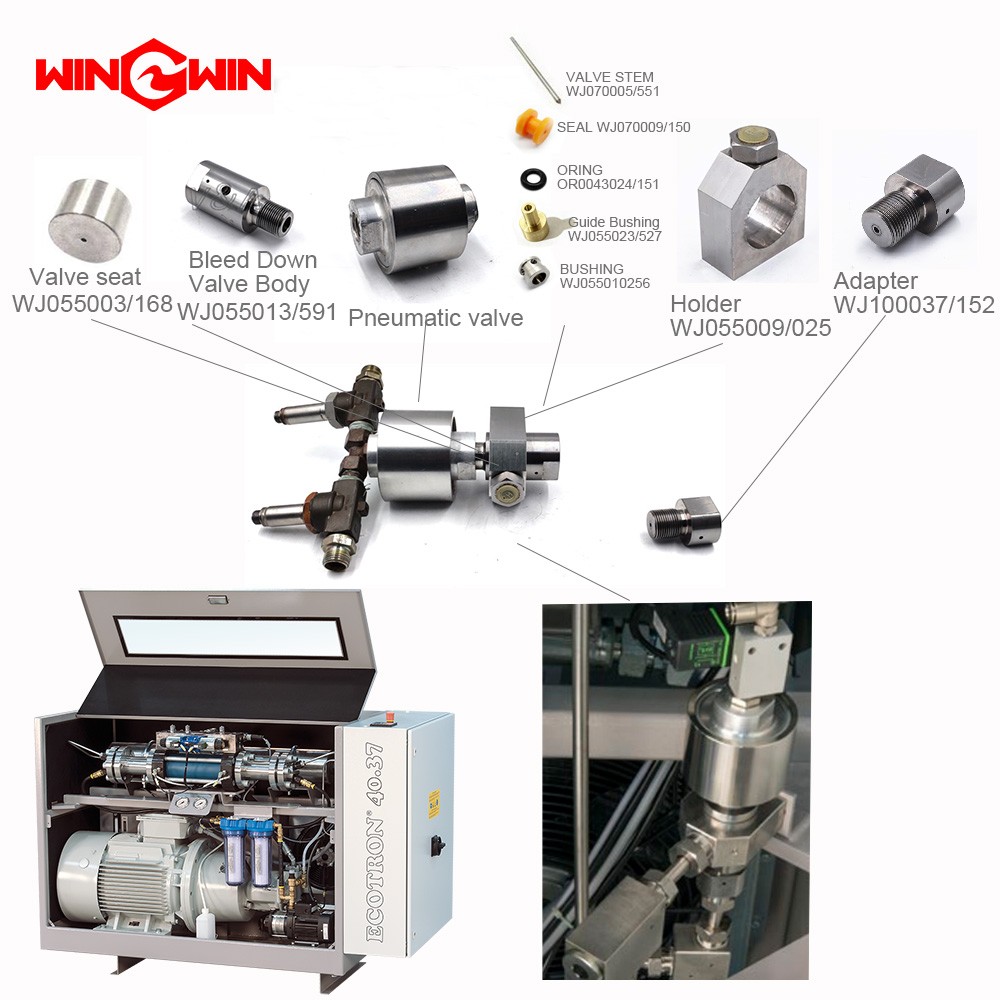

| CP022047/844 | Pressure valve |

| CP022019/844 | suction valve |

| MA160818/220 | swivel male elbow |

| OR0759017/151 | o-ring75.92*1.78 |

wwaterjet

wwaterjet