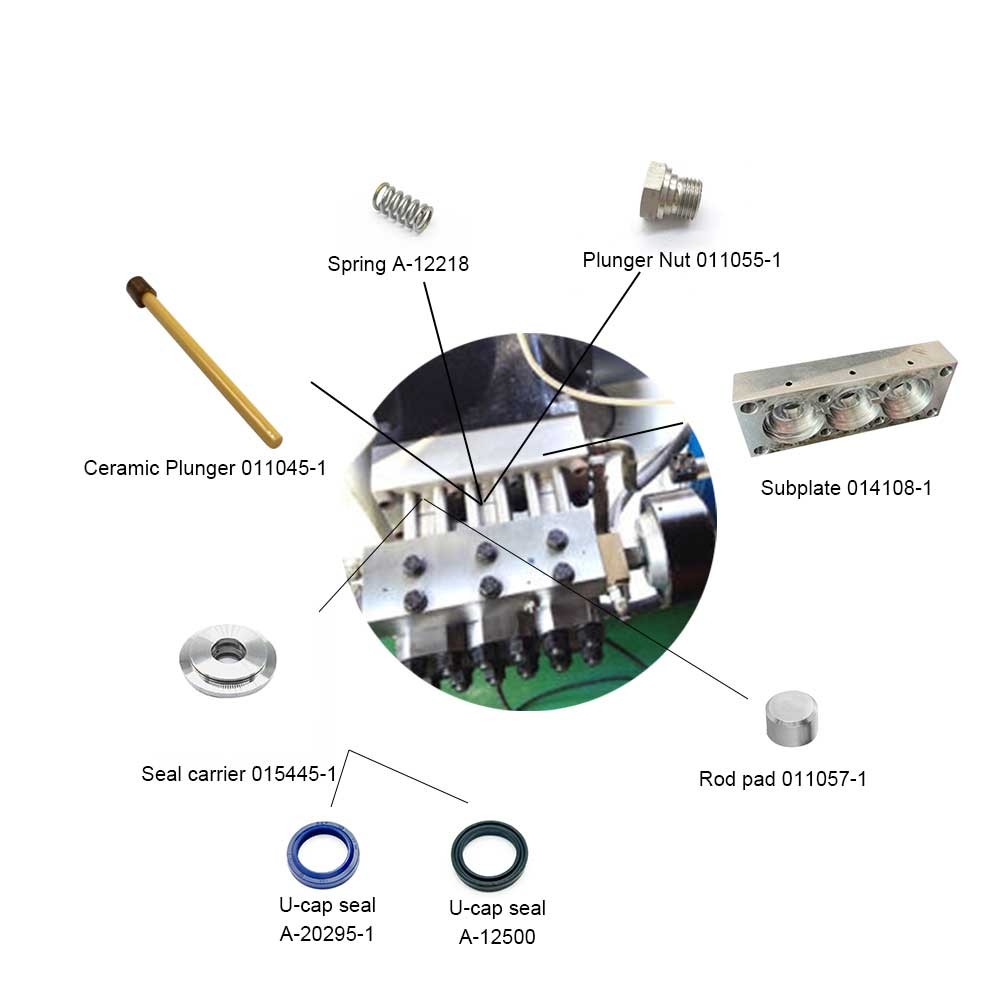

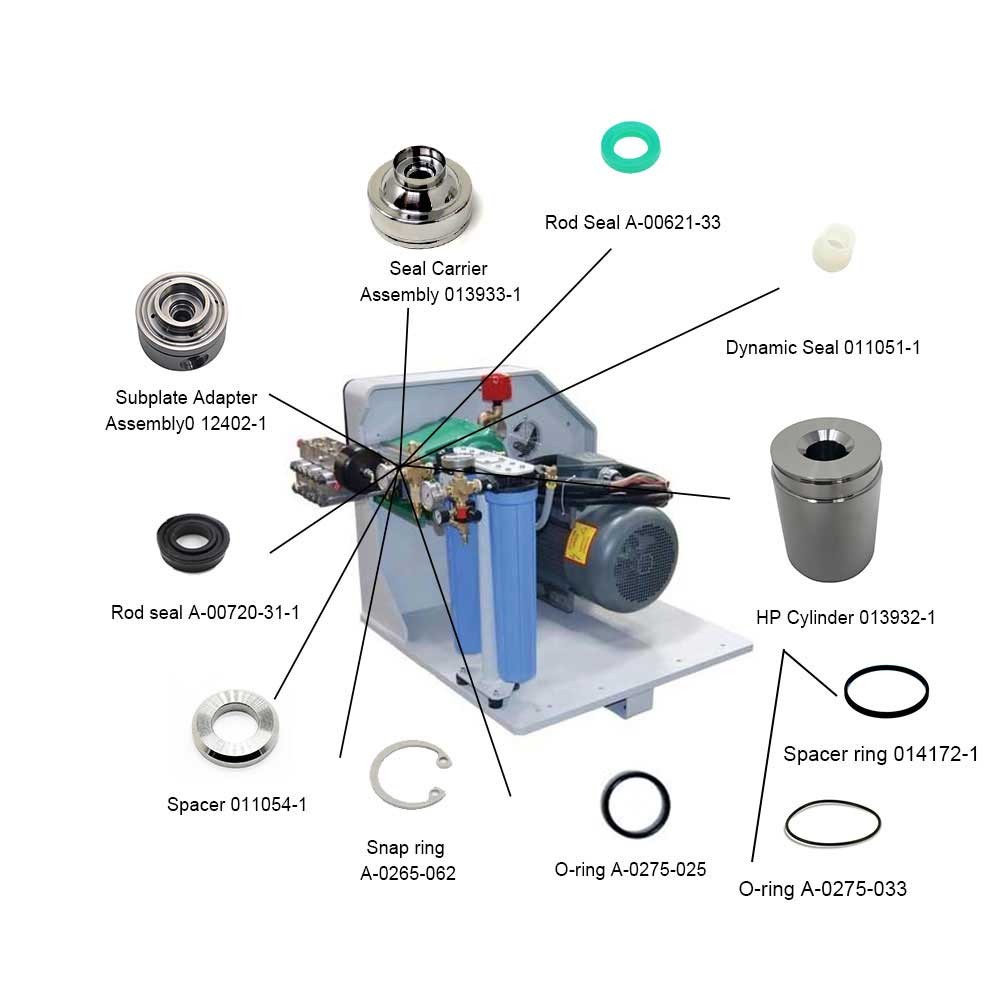

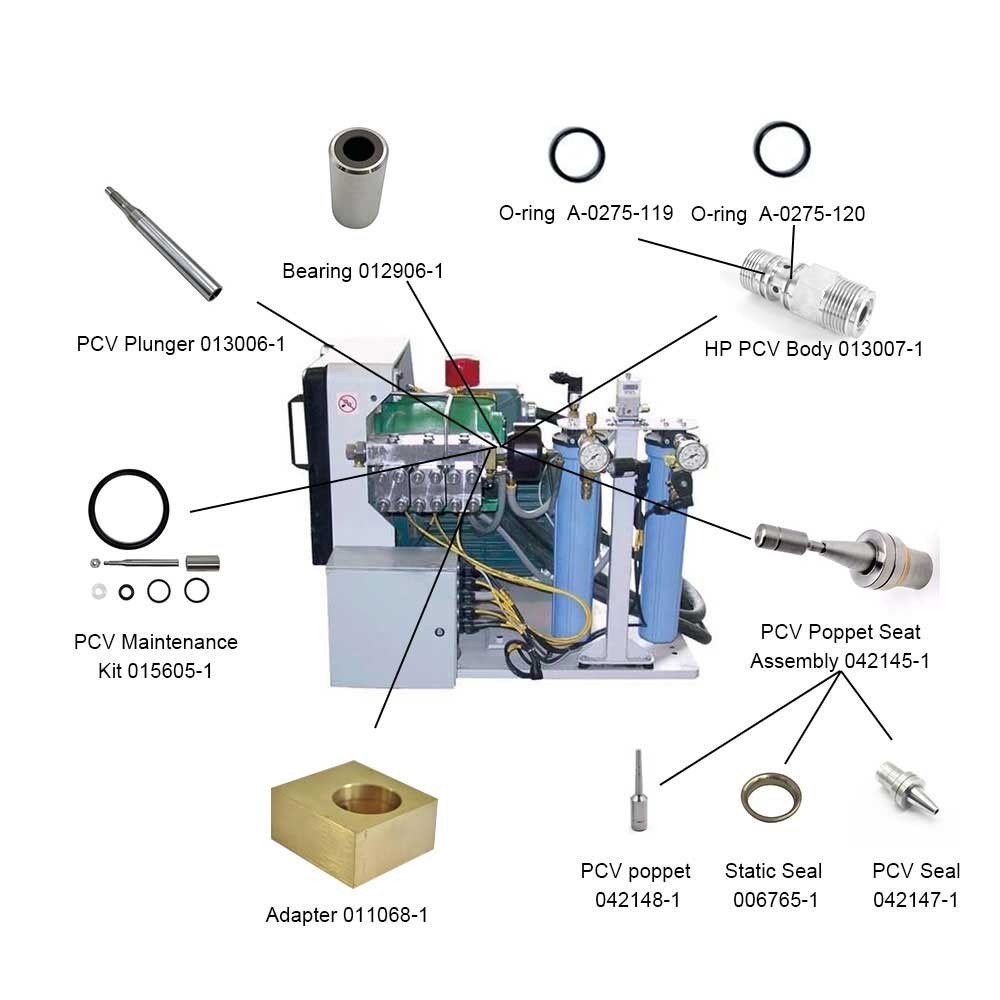

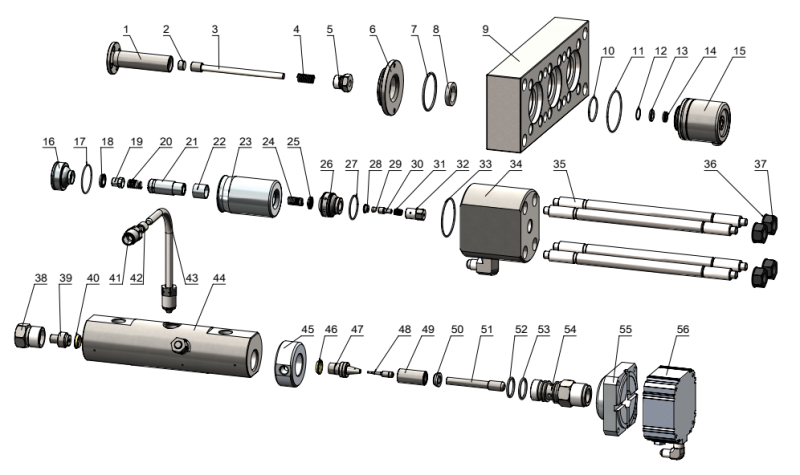

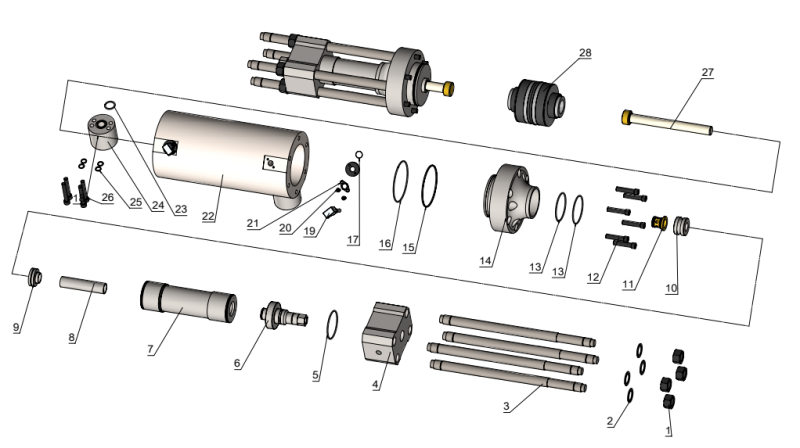

Direct Drive pump HP TUBE TOLLING KIT

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

Direct drive pumps, also known as electric pumps, work by using an electric motor to turn a pump shaft, which in turn rotates an impeller or rotor to create fluid flow and generate pressure. This type of pump is commonly used in applications such as water supply, irrigation, and HVAC systems, where the requirements for pressure and flow are moderate.

One of the main advantages of direct drive pumps is their simplicity. They have fewer components than other types of pumps, which makes them easier to maintain and less prone to failure. They are also more energy-efficient than other types of pumps, as they do not require an intermediary component to convert the motor's energy into hydraulic pressure.

Intensifier pumps, also known as hydraulic pumps, work by using a hydraulic intensifier to increase the pressure of the incoming fluid. They are commonly used in applications such as waterjet cutting, where high pressure and precision are critical.

The hydraulic intensifier in an intensifier pump works by using a small piston to amplify the pressure of the incoming fluid. The amplified pressure is then transmitted to a larger piston, which generates the high-pressure output. This type of pump is capable of generating much higher pressure outputs than direct drive pumps, making them ideal for applications that require high pressure and precision.

One of the main advantages of intensifier pumps is their ability to generate extremely high pressure outputs. They are capable of generating pressures of up to 100,000 psi or more, making them suitable for applications such as waterjet cutting, where high pressure and precision are critical. However, they are more complex than direct drive pumps and require more maintenance.

In summary, the choice between direct drive pumps and intensifier pumps ultimately depends on the specific requirements of the application. Direct drive pumps are a good choice for applications that require moderate pressure and flow rates, while intensifier pumps are better for applications that require high pressure and precision.

wwaterjet

wwaterjet