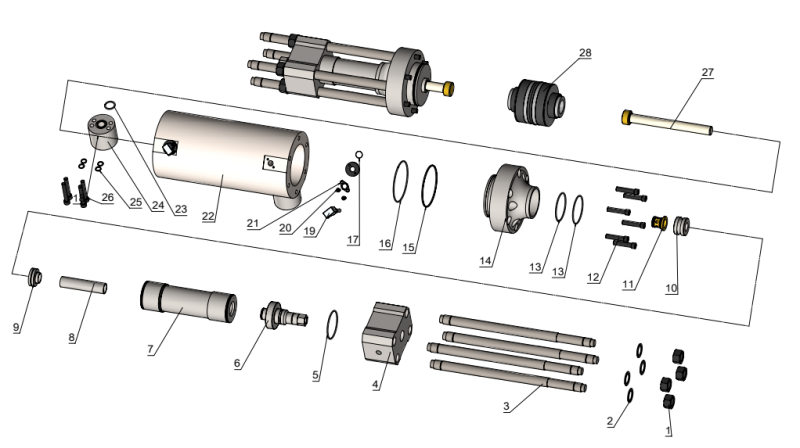

Direct Drive pump Blue Goop A-2185

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

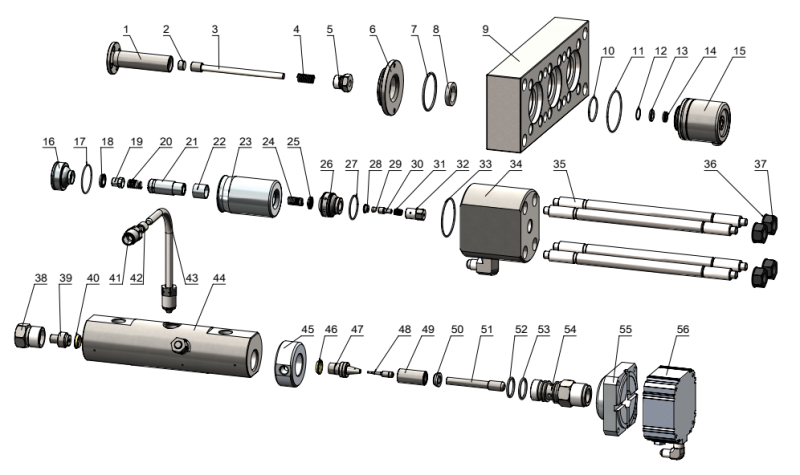

Both direct drive pumps and intensifier pumps have their own advantages and disadvantages, and the choice between the two ultimately depends on the specific application and requirements.

Direct drive pumps are typically more cost-effective, energy-efficient, and easier to maintain than intensifier pumps. They work by directly converting the motor's rotational energy into hydraulic pressure, eliminating the need for a separate intensifier component. This results in a simpler system with fewer parts that are less prone to failure.

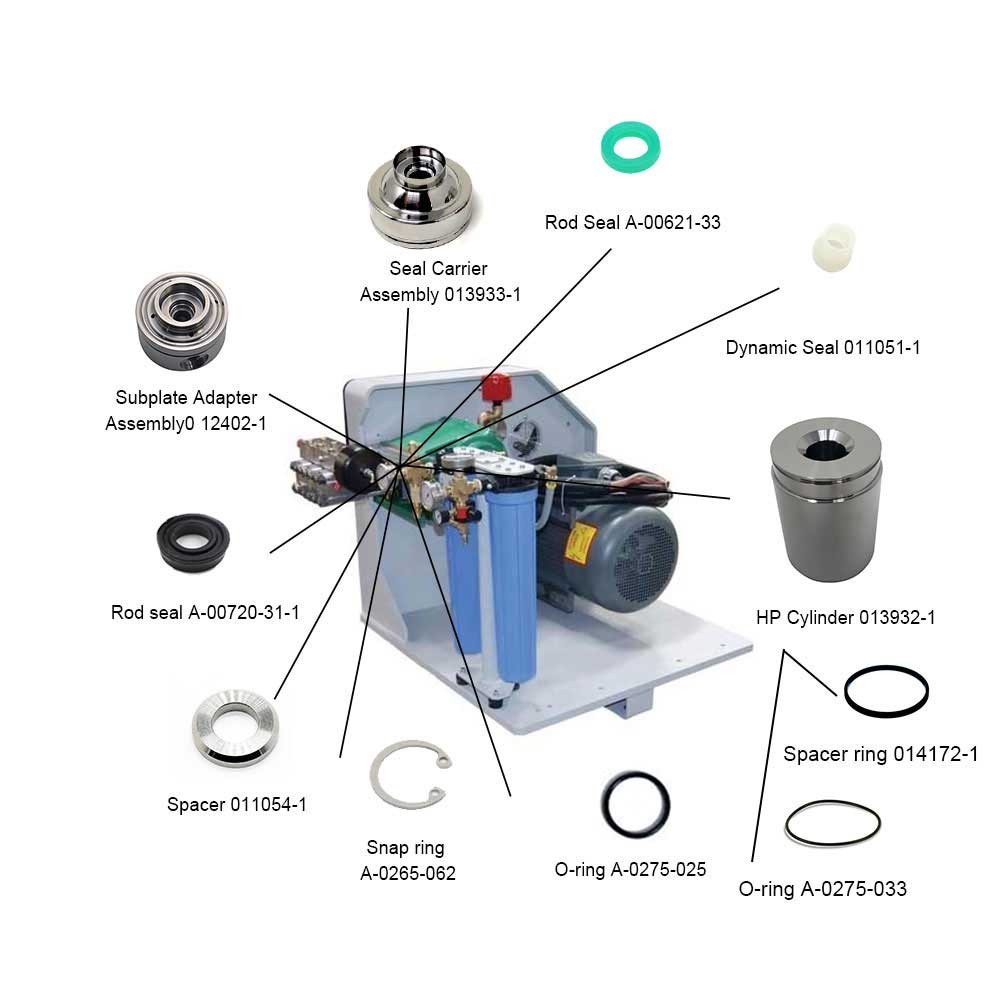

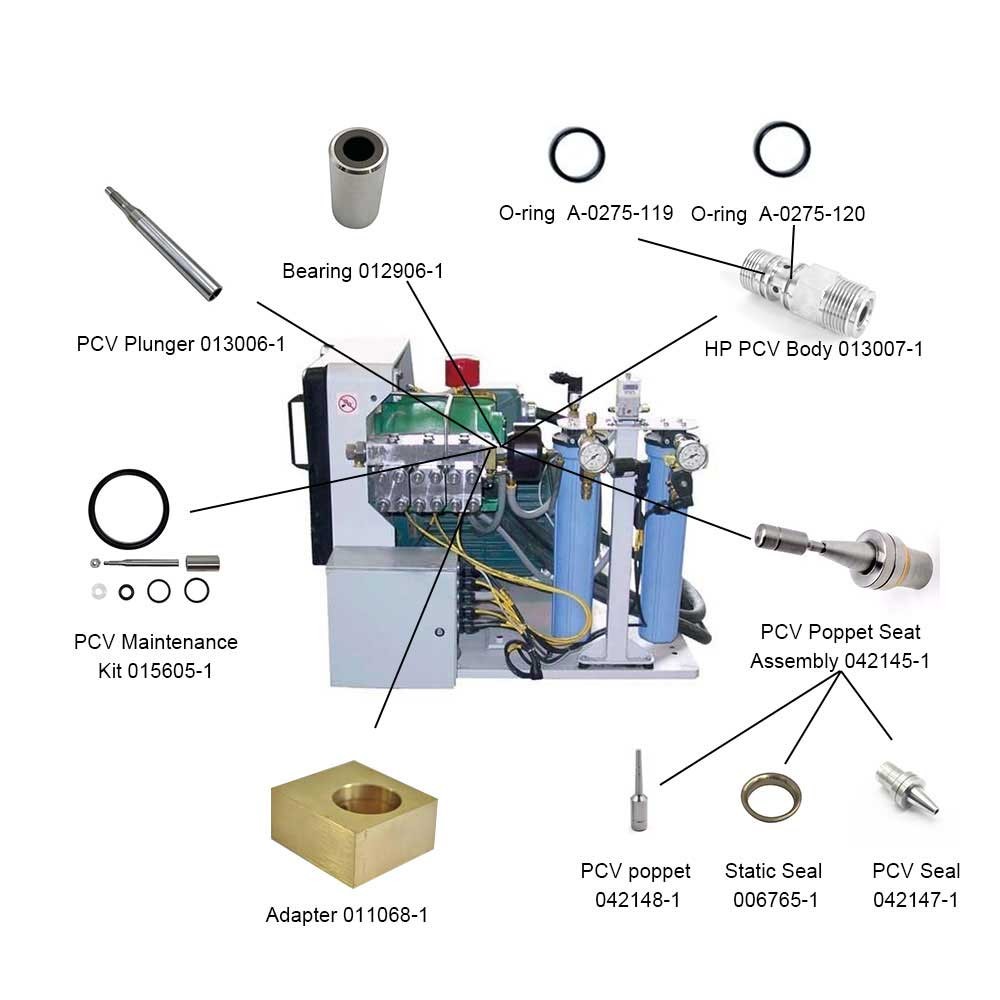

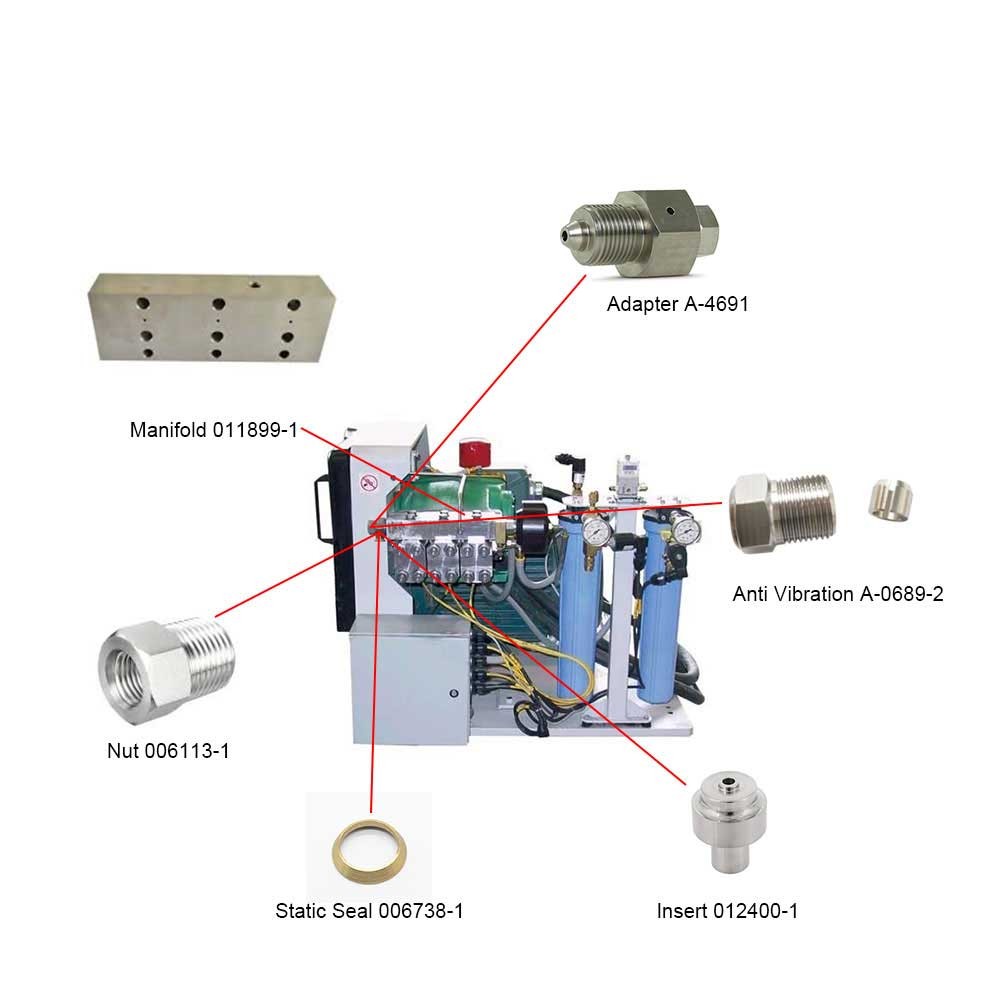

Intensifier pumps, on the other hand, are better suited for applications that require high pressure and precision. They work by using a hydraulic intensifier to multiply the pressure of the incoming fluid, allowing them to achieve much higher pressure outputs than direct drive pumps. This makes them ideal for applications such as waterjet cutting, where high pressure and precision are critical.

In summary, direct drive pumps are a good choice for applications that require moderate pressure and flow rates, while intensifier pumps are better for applications that require high pressure and precision. Ultimately, the choice between the two depends on the specific requirements of the application.

wwaterjet

wwaterjet