REPLACEMENT Waterjet parts High pressure Coil Tube

Description

Robotic Piping Kits: FANUC M20 Axis 3 Coil

Item number: 120IB-C-3CT

Details: used on the FANUC M20IA robot arms, axis 3 coil

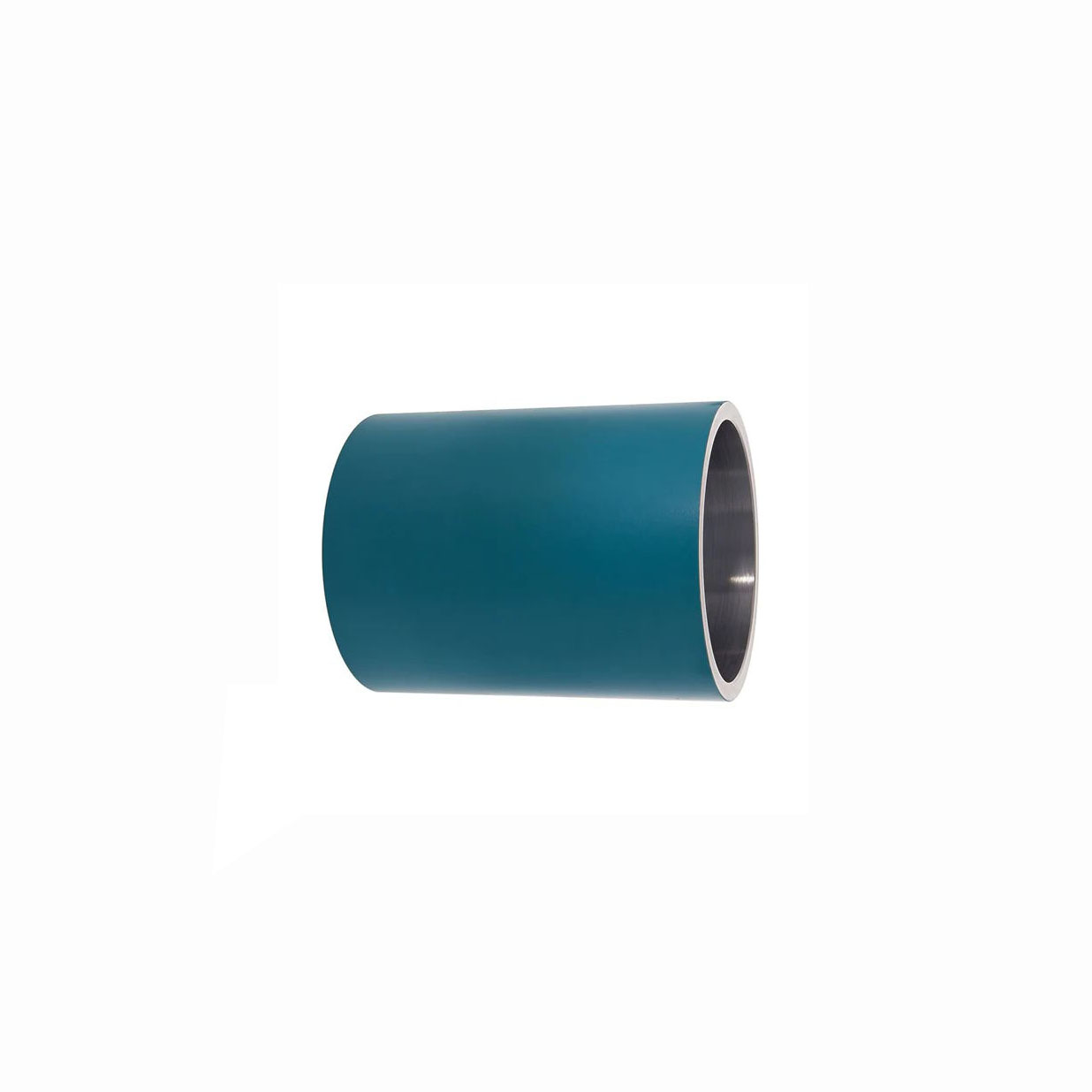

Waterjet coil and cutter head:

The Waterjet parts High pressure Coil Tube and cutter head are robot water cutting parts that often need to be inspected during the use of the robot.

First of all, you need to check the cutting head parts regularly. If the cutting surface is uneven, the cut is not thorough, and the water flow is unstable, you need to stop the machine and replace the parts in time. It is recommended to choose the WINWIN water cutting reverse osmosis water filtration system, which can avoid the short service life of water jet parts due to water impurities.

Secondly, the Waterjet parts High pressure Coil Tube should be checked frequently to see if there are leaks, coil deformation, etc. to ensure that water jet cutting will not be difficult due to coil problems.

The maintenance of robot waterjet cutting system is the top priority to ensure the normal operation of the water cutting system.

Paying attention to the status of each component and solving discovered problems in a timely manner can make the waterjet robot more durable and ensure production efficiency. At the same time, we also need to know that when we encounter a problem that cannot be solved, we should contact WINWIN waterjet in time to solve the problem for you.

What industries is robotic waterjet used in?

Robotic waterjet cutting is used in a variety of industries where precision cutting, material versatility, and automation are important. Some of the key industries that employ robotic waterjet technology include:

Aerospace: Robotic waterjet cutting is used for cutting and shaping components in the aerospace industry, including aircraft parts, engine components, and interior materials. It is valued for its ability to handle materials like titanium, aluminum, and composites with precision.

Automotive: In the automotive industry, robotic waterjet cutting is employed for cutting and shaping metal and non-metal materials, including sheet metal, rubber, and plastics. It's used in the production of vehicle components, interior materials, and specialized parts.

Manufacturing: General manufacturing industries utilize robotic waterjet cutting for a wide range of applications, including cutting machine parts, tools, gaskets, and custom components from various materials.

Marine: Robotic waterjet cutting is used to cut and shape materials used in shipbuilding and marine applications. It's suitable for cutting metals, composites, and other materials for hulls, interiors, and other marine components.

Construction and Architecture: In the construction and architecture sectors, robotic waterjet cutting is used for shaping architectural details, decorative elements, and customized building materials. It's especially valuable for cutting stone, glass, and ceramics.

Renewable Energy: The renewable energy industry employs robotic waterjet cutting for cutting materials used in solar panels, wind turbine components, and hydropower equipment. It's used for precise cutting of various materials, including composites.

Food Processing: In the food industry, waterjet cutting is used for precise cutting and portioning of food products, such as meat, vegetables, and baked goods. It ensures clean and hygienic cutting without crushing or contaminating the products.

Electronics: Robotic waterjet cutting is used to cut and shape electronic components, printed circuit boards (PCBs), and specialty materials used in the electronics manufacturing process.

Medical Devices: The medical device industry employs robotic waterjet cutting for precision cutting of materials used in medical instruments, implants, and equipment.

Art and Design: Robotic waterjet cutting is utilized in the creation of artistic and architectural elements, including sculptures, intricate designs, and decorative pieces. It allows for detailed and precise cutting of various materials.

Defense and Military: The defense industry uses robotic waterjet cutting for producing military equipment, vehicle components, and specialized materials used in defense applications.

Oil and Gas: In the oil and gas sector, waterjet technology is employed for cutting materials used in pipelines, equipment, and components in harsh environments.

These are just a few examples of industries where robotic waterjet cutting technology is applied. Its versatility and precision make it a valuable tool in various sectors where the need for precise, clean, and material-flexible cutting is essential.

If you are looking for robot water cutting system suppliers or robot waterjet parts suppliers, as well as technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

wwaterjet

wwaterjet