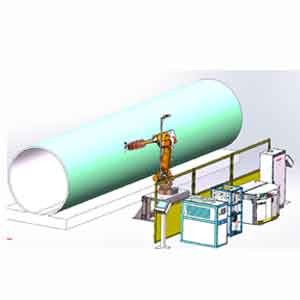

Waterjet robot water pipe cutting

The key advantages of using a robotic waterjet cutting system over traditional cutting methods are:

Increased Flexibility and Versatility:

Waterjet cutting can handle a wide range of materials, including metals, composites, plastics, and even delicate materials like glass and ceramics.

The robotic arm provides a high degree of flexibility, allowing for complex, intricate, and customized cuts that would be difficult or impossible with other cutting methods.

Improved Precision and Accuracy:

Waterjet cutting can achieve very tight tolerances, often within ±0.1 mm, due to the focused and stable nature of the water jet.

The robotic control system enables precise and repeatable cuts, even on complex geometries, resulting in higher-quality parts.

Reduced Heat-Affected Zone:

Waterjet cutting is a cold cutting process, meaning it does not generate significant heat during the cutting operation.

This eliminates heat-related issues such as warping, discoloration, and metallurgical changes, especially important for heat-sensitive materials.

Enhanced Safety and Environmental Benefits:

The submerged cutting process in the water tank helps contain the water, abrasives, and debris, improving workplace safety and reducing the environmental impact.

Waterjet cutting does not produce harmful fumes or particulates, making it a more environmentally friendly cutting solution compared to thermal processes like plasma or laser cutting.

Increased Productivity and Efficiency:

The robotic automation and high-pressure water jet can significantly increase cutting speeds and material removal rates.

The versatility of the system allows for streamlined production, as a single robotic waterjet can handle a wide range of materials and parts, reducing the need for multiple specialized machines.

Reduced Material Waste:

Waterjet cutting produces a narrow kerf width, typically less than 1 mm, resulting in minimal material waste compared to other cutting methods.

The precision of the robotic system further reduces material waste by optimizing part nesting and cutting patterns.

These key advantages make the robotic waterjet cutting system a highly attractive solution for various industries, including metal fabrication, aerospace, automotive, construction, and more, where the need for flexibility, precision, and efficiency is paramount.

Configuration of waterjet robot water pipe cutting

Pressure: 360MPa-420MPa

1: Structure Design

2: ABB 1600 robot arm

3: Equipped with SL-VI 50 HP intensifier pump

4: Industrial chiller

5: Vacuum adsorption system

6: Water purification system

7: Safety protection system

8: General control system

Advantages of Waterjet Pump

| Brand | WINWIN | Model | SL-VI 50HP |

| Name | Water jet servo motor pump | Temperature | 5-40°C |

| Working pressure | 420Mpa | Driving mode | Servo motor |

| Material | Material | Application | Water jet cutting system |

| Voltage | 380V | Rated power | 50HP |

| Attenuator capacity | 1L | Continuous working pressure | 320Mpa-380Mpa |

| Maximum water flow | 3.8L/min | Number of orifices | 3(0.17mm) |

| Tank volume | 150L | Size (L * w * h) | 2.2m*1.4m*1.6m |

| Weight | 1.5T |

If you are interested in Waterjet robot water pipe cutting,contact us now.

wwaterjet

wwaterjet