Robotic waterjet cutting is a cold cutting process, making it ideal for automotive, medical and aerospace applications where the material cannot be affected by heat. Nearly every type of cut is possible, from using waterjet tables for rapid hole drilling to detailed cuts for automotive applications. Waterjet robot cutters use an abrasive additive to create a clean, burr-free cut that does not require secondary finishing – saving both time and money.

Waterjet Cutting Cell | Technology by Shape Process Automation

Robotic waterjet cutting has become an almost unavoidable step in the manufacturing process of a large percentage of automotive components. From 2-dimensional flat stock to 3-dimensional molded components, metals to fabric and plastic composites, waterjet has proven to be an effective, efficient machine tool.

| 1 | Brand of robot arm: | YASKAWA | |

| 2 | Model: | GP20HL | |

| 3 | Style: | Pedastal | |

| 4 | Quantity of robot arm: | Single | |

| 5 | Application: | Automotive interior cutting | |

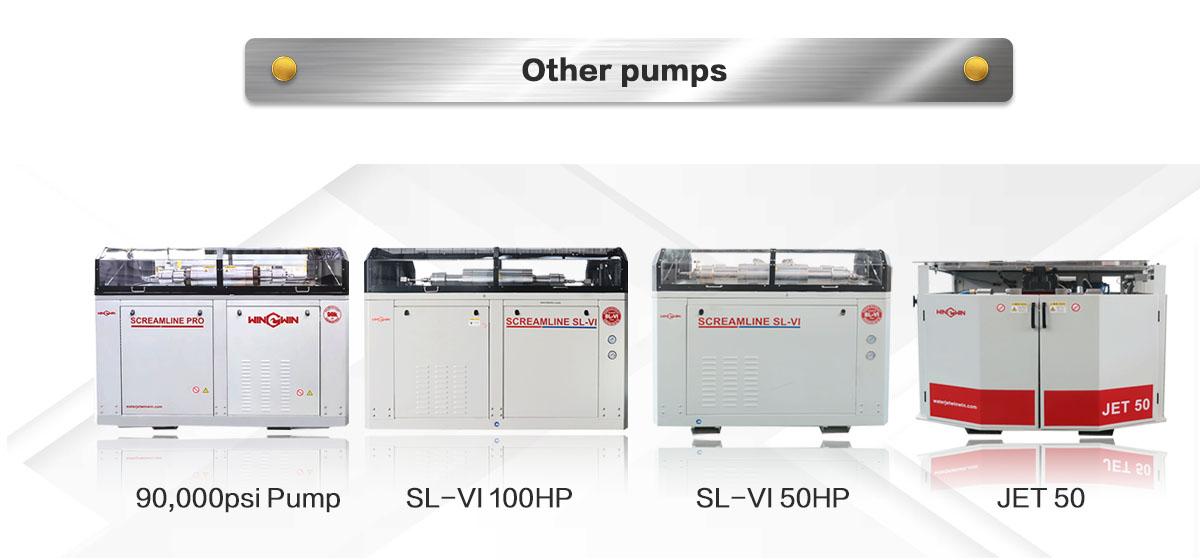

| 6 | Pump type: | STREAMLINE SL-VI 100 HP Large Flow Intensifier Pump | |

| 7 | Oprator required: | 2 sets | |

| 8 | Customize avialable: | Yes | |

| 9 | Including devices: | Robot arm, cutting table, high-pressure pump, chiller, control system, etc.. | |

This robotic waterjet cutting system is an economical design.

First of all, under the condition of limited funds, the robotic waterjet cutting workstation equipped with a single robot arm can cut the test parts of the automotive interior, or process the new car interior in small batches. Generally speaking, new cars are produced or new cars are developed. A small number of trial pieces are required at all times.

Single arm robot waterjet cutting system has high flexibility and is suitable for customers who need to frequently change cutting models. It is easy to operate and has fast programming. Equipped with a 100HP large-flow intensifier pump, it is very cost-saving.

This workstation is equipped with two front and rear workbenches, which can cut two different car interior parts at one time. If the customer is just starting out or needs to cut a large number of parts and a small quantity, choose this structure. Robotic waterjet cutting is a smart choice.

WINWIN has shipped such robotic waterjet cutting structures to customers in many countries, and the customers are satisfied with their use.Now they have purchased high-efficiency robotic waterjet cutting structures from us again, we use this simple and economical robotic waterjet cutting to help customer go through the transition period of production.

When the customer's business and required productivity are getting bigger and bigger, we will upgrade the equipment or reinstall a set of high-efficiency robot waterjet cutting system for the customer. This is also the preference of many customers to choose.

Advantages of Waterjet Cutting

No heat or chemicals are used. Only pure water

No Material Deformation caused by heat

No Hazardous Fumes or Vapors

No need to clean or sharpen the cutting tool

No Reworking, or minimal reworking

No Compression cutting

Configuration of Robotic waterjet cutting

1: Pedestal Working Station

2: Yaskawa GP20HL robot arms of Robot Waterjet Cutting System

3: Equipped with WIN-WIN STREAMLINE SL-VI 100 HP Large Flow Intensifier Pump

4: High-performance industrial chiller

5: The powerful vacuum adsorption system

6: Water purification system, which can prolong the service life of orifice

7: Safety protection system to detect personnel in the work area and protect personnel safety

8: General control system

Robotic waterjet cutting intensifier pump with servo motor

1.Supply multiple cutting heads

2.Low noise

3.Pressure stability

4.Prolong the life of high pressure parts

5.Energy saving 20%

6.large-capacity accumulator

7.The automatic protection system

| Brand | WIN-WIN | Name | Waterjet servo motor intensifier pump |

| Model | SL-VI (100HP) | Working ambience | 5-40°C |

| Driving mode | Servo motor | Application | Robot waterjet cutting system |

| Power | 220V/380V | Rated power | 100HP |

| Capacity of attenuator | 2L | Max work pressure | 420Mpa |

| Maximum water flow rate | 7.6L/min | Number of orifices | 6 |

| Oil tank volume | 220L | Dimension(L*W*H) | 2.2m*1.4m*1.6m |

| Weight | 1.5t |

Why choose WINWIN Robotic Waterjet Cutting?

Robotic waterjet cutting technology is very mature, but if you want to use high-end robot waterjet cutting system, please choose WINWIN waterjet cutting cell, WINWIN waterjet cutting technology is more professional.

WINWIN waterjet has won the trust of many customers and established long-term cooperative relations. The reasons are as follows.

The first is the robot waterjet cutting technology of WINWIN waterjet. The development of WINWIN company comes from technology. Because of its cutting-edge research and development technology, it has been developing so far.

The second reason is that WINWIN has a huge scale. WINWIN has been engaged in the robot waterjet cutting industry for many years, and now it has developed into a systematic company. Each production process is very mature and have our own production plants and offices. The department is equipped with sufficient personnel, and we will operate robot waterjet cutting system for a long time.WINWIN company promises that we will continue to carry on in the robot waterjet cutting industry. Solve problems for customers.

The third reason is that the price of WINWIN's robot waterjet cutting equipment is very favorable. Under the condition of ensuring product quality, WINWIN will give customers more discounts. Robotic waterjet cutting has high cutting precision and various types of cutting, which can fully meet the needs of customers.

If you also want to use the robot waterjet cutting system to cut your material, please click to consult us.

1.Used for the waterjet robot 3D waterjet cutting intensifier pump servo motor can save 30% cost

2.60,000psi ultra-high pressure,guaranteed cutting speed

3.3.6L/min large flow intensifier pump design,can drive1-5 waterjet robots at the same time

4.Adopt the latest technology,reduce the faliure rate and reduce the maintenance cost

5.Water jet robots Intensifier pump parts are universal in the world

wwaterjet

wwaterjet