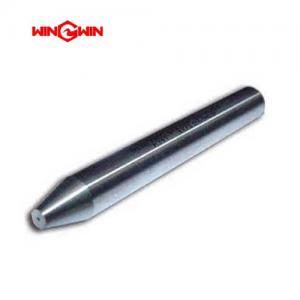

REPLACEMENT Robotic Waterjet parts Coil 301039

Robotic Waterjet parts Coil 301039 Description

Item number: 301039

Details: Robotic Waterjet parts Coil 301039 used on IRB2400 Axis 5 and 6 robot waterjet cutting system

The robot arm is the main part of the robot project. WINWIN rationally designed the robot arm and customized the high-pressure coil. The water jet was placed at the end of the sixth axis of the robot for fixation. According to the spatial curve changes of the workpiece and the direction of the fluid surface, the robot It can respond in real time, adjust the cutting route in a timely manner, accurately cut complex parts, and meet the complex and changeable production requirements of various workpieces. This structural design is designed to maximize the production process requirements and improve production efficiency. In this workstation, the setting of dual-station dual manipulators can meet the positioning of efficient production.

Robotic Cutting

In most robotic waterjet cutting systems, the cutting head is attached to a robot arm. For three dimensional waterjet cutting, industrial robots and motion control technology are used, thus providing unrivalled flexibility, which is crucial considering the constant changes made to production processes.

It is, for example, very easy to modify the cutting program so that several tasks are carried out simultaneously. There is no need for a system reset or similar operation. Robotic waterjet cutting is very safe, cost-effective, productive and protect the environment because they provide a viable alternative to conventional machining methods such as sawing, thermal cutting (plasma/laser), punching, milling and other mechanical processes (deburring of cast and forged parts or composites).

https://www.youtube.com/watch?v=5ovf15q081A&list=PLIRM1tPqc2GDBjoX-a4OTrMj9uNRCMTgY&index=1

Overall introduction to waterjet products

Three dimensional systems are designed for demanding applications. By using a cutting head with five axes, cones can be cut from flat sheets, holes can be drilled into tubes and ribbed/beveled edges can be produced. While such flexible systems come at a price, they can be used in the most advanced cutting applications and normally pay for themselves as they are extremely versatile:

The waterjet cutting machine can cut marble, ceramic tiles, metal, rubber, aerospace materials, automotive interiors, ship interiors, chemical pipelines, oil pipelines, etc.

Water cutting uses a booster pump to pressurize 0.2Mpa water to 350Mpa or higher, and spray it through a small water pipe hole on the cutting head. Mix sand and use high-speed sand particles for cutting.

You can also cut without adding sand (pure water cutting)

Water is pumped through the reciprocating motion of the piston, and is sent to the accumulator to be pressurized and then ejected from the cutting head for cutting.

There are two principles of water cutting, one is a direct drive pump and the other is a hydraulic pump.

Robot water cutting equipment: about 800,000-1.2 millionRMB. A set of annual consumables is about 100,000 RMB

Customer groups of this type of equipment: large customers, group customers, facing procurement, engineering departments, operators, superiors, bosses, etc.

The equipment cycle is generally 3-8 months.

The cost of water cutting in Gaza is about 200,000-400,000RMB, and a set of annual consumables is about 40,000-50,000RMB.

The cycle is 2-5 months, and each device consumes 30000-50000 RMB per year.

The customer groups of this type of equipment are: small workshops, medium-sized enterprises, large companies, group companies, there are many customer groups.

Portable water cutting: about 150,000-200,000 RMB, a set of annual consumables is about 20,000 RMB

Customer groups for this type of equipment: small customers with simple needs who need customization.

Robotic water cutting can be roughly divided into three categories:

Upside-down type: upside-down 2/3/4 hand workstation, upside-down 2/3/4 hand rotating workbench workbench

Seated type: Seated one-hand dual-station robot workstation, Seated two-hand dual-station robot workstation

Side-mounted: side-mounted two-hand workstation

| Basic Layout Design of Three types of Waterjet Machine (Examples) | ||

| Robotic seated rotating dual-station workstation | Abrasive waterjet Machine | Portable waterjet Machine |

| Stationary Cutting Table - 2 Workpieces | Cutting Table | |

| ABB IRB 4600 ROBOT - 2 Arms | Control system | Magnetic Car |

| Intensifier Pump | Intensifier Pump | Intensifier Pump |

| Cooling System | Water Cooling system | Cooling chiler |

| Water Filtration System | Water Filtration System(Not necessary) | Thermoplastic hose |

| Vacuum Adsorption System | Abrasive Feeder Tank | Abrasive Tank(can use 8-10H) |

| General Control System | Abrasive valve | |

| Security Barrier | ||

| Manual operation box | ||

Waterjet machine parts: KMT, BFT (BHDT) FLOW, JET EDGE, WSI, ACC, OMAX,

China: Dadi, APW, etc.

If you are looking for robot waterjet cutting system suppliers or Robotic Water jet Coils suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

wwaterjet

wwaterjet