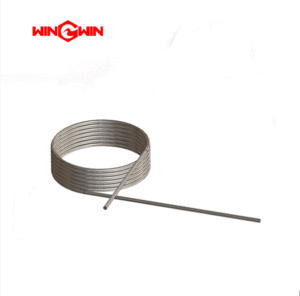

REPLACEMENT Robotic Waterjet parts Coil 304297

Robotic Waterjet parts Coil 304297 Description

Industries where ultra-high pressure waterjet is applied

Ultra-high pressure waterjet technology is applied in a wide range of industries due to its versatility, precision, and effectiveness in cutting, cleaning, and surface preparation. Some of the key industries where ultra-high pressure waterjet is commonly used include:

1.Manufacturing and Metalworking:

Cutting and shaping metal components, including aerospace parts, automotive frames, and precision engineering.

Removing excess material, deburring, and cleaning metal surfaces.

2.Aerospace:

Precision cutting of composite materials for aircraft structures.

Surface preparation and cleaning for aerospace components.

3.Automotive:

Cutting and shaping various automotive components.

Removing coatings, paint, and rust from car bodies and parts.

4.Construction and Architecture:

Cutting concrete and stone for construction projects.

Artistic and architectural detailing in stone and glass.

Surface cleaning and restoration of historical buildings.

5.Manufacturing and Fabrication:

Cutting and shaping materials used in machinery and equipment manufacturing.

Weld seam removal and preparation of materials for welding.

6.Marine and Shipbuilding:

Cutting and shaping ship components and structures.

Cleaning ship hulls and removing marine growth.

7.Oil and Gas:

Maintenance of oil rigs and platforms.

Cutting and decommissioning of pipelines and structures.

Cleaning and surface preparation for offshore equipment.

8.Renewable Energy:

Cutting components for wind turbines and solar panels.

Maintenance of hydropower turbines.

9.Food Industry:

Cutting, slicing, and portioning of food products.

Cleaning and sterilization of food processing equipment.

10.Mining and Quarrying:

Cutting and shaping of stone and minerals.

Controlled rock splitting in mining operations.

11.Environmental Services:

Cleaning and maintaining wastewater treatment plants.

Removing graffiti from surfaces in urban areas.

12.Nuclear Industry:

Precision cutting and dismantling of nuclear components.

Decontamination and surface preparation in nuclear facilities.

13.Defense and Military:

Cutting and shaping components for defense equipment.

Maintenance of military vehicles and aircraft.

14.Electronics and Semiconductor Manufacturing:

Precision cutting and profiling of electronic components.

Cleaning and etching of semiconductor materials.

15.Paper and Pulp Industry:

Cutting and shaping paper products.

Cleaning and maintenance of equipment in paper mills.

16.Medical and Healthcare:

Precision cutting of medical instruments and devices.

Cleaning and sterilization of medical equipment.

17.Textile Industry:

Cutting textiles and fabrics with precision.

Edge sealing of synthetic textiles.

18.Art and Sculpture:

Creating intricate sculptures and art pieces from various materials.

Surface detailing and texturing for artistic work.

Ultra-high pressure waterjet technology is continually evolving and finding new applications across various industries. Its ability to cut a wide range of materials cleanly and accurately, without the generation of heat or hazardous byproducts, makes it an attractive choice for many manufacturing and maintenance processes.

If you are looking for robot waterjet cutting system suppliers or Robotic Water jet Coils suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

wwaterjet

wwaterjet