High pressure water jet cutting machine to cut metal

The advantages of water jet cutting and waterjet spare parts are not only obvious to all, but also recognized by more and more enterprises. As a kind of cold cutting process, it has many advantages that other cutting technologies can't do. Because of this, you can do many things with water jet cutting, one of which is metal processing. High pressure water jet cutting machine uses high pressure water jet to cut metal materials at a very high speed.

The quality of the cutting surface after the water jet cutting machine with waterjet spare parts cuts the aluminum alloy plate is good, the surface finish can reach ra25, the positioning accuracy is ± 0.1mm, the repeated positioning accuracy is ± 0.50mm, the dimensional tolerance of the cutting straight line is ± 0.10mm, and the slope of the cut section is less than 0.1mm. The worktable of our water jet cutting machine with waterjet spare parts is 2000 * 4000. The aluminum alloy plate processed by water jet cutting machine can meet the requirements of the above standards. The workpiece cut by water jet cutting machine with waterjet spare parts does not need to carry out subsequent processes such as grinding, trimming and processing, but the cutting speed of aluminum alloy thick plate cut by water jet cutting machine with waterjet spare parts is slow, and the cutting of plates with the same thickness and material is about half of that of laser and plasma cutting.

The cutting accuracy of the laser cutting machine is good. After cutting the aluminum alloy plate, the quality of the cutting surface is good, the surface finish can reach ra25, the positioning accuracy is ± 0.10mm, the repeated positioning accuracy is ± 0.1mm, the dimensional tolerance of the cutting straight line is ± 0.30mm, and the slope of the cut section is less than 0.2mm. Within the range of laser cutting capacity, the laser cutting function can meet the cutting quality standard requirements of aluminum alloy car blanking. And the cutting speed of laser cutting machine is fast. However, a large number of burrs will be produced when the laser cutting machine cuts the aluminum alloy plate with a thickness of more than or equal to 4mm. Subsequent treatment of deburring is required.

The quality of the cutting surface after plasma cutting machine cutting aluminum alloy plate is worse than that of laser and water cutting machine, and the surface finish should preferably reach ra25. Therefore, when cutting aluminum alloy workpiece by plasma cutting machine, 3-5mm machining allowance shall be reserved on one side according to the nominal size of the workpiece, which wastes certain raw materials. If the use function of the workpiece is not affected, the deburring workpiece cut by the plasma cutting machine can also be directly used for assembly welding. So waterjet cutting machine with waterjet spare parts is more effective to cut materials.

How waterjet cutting works

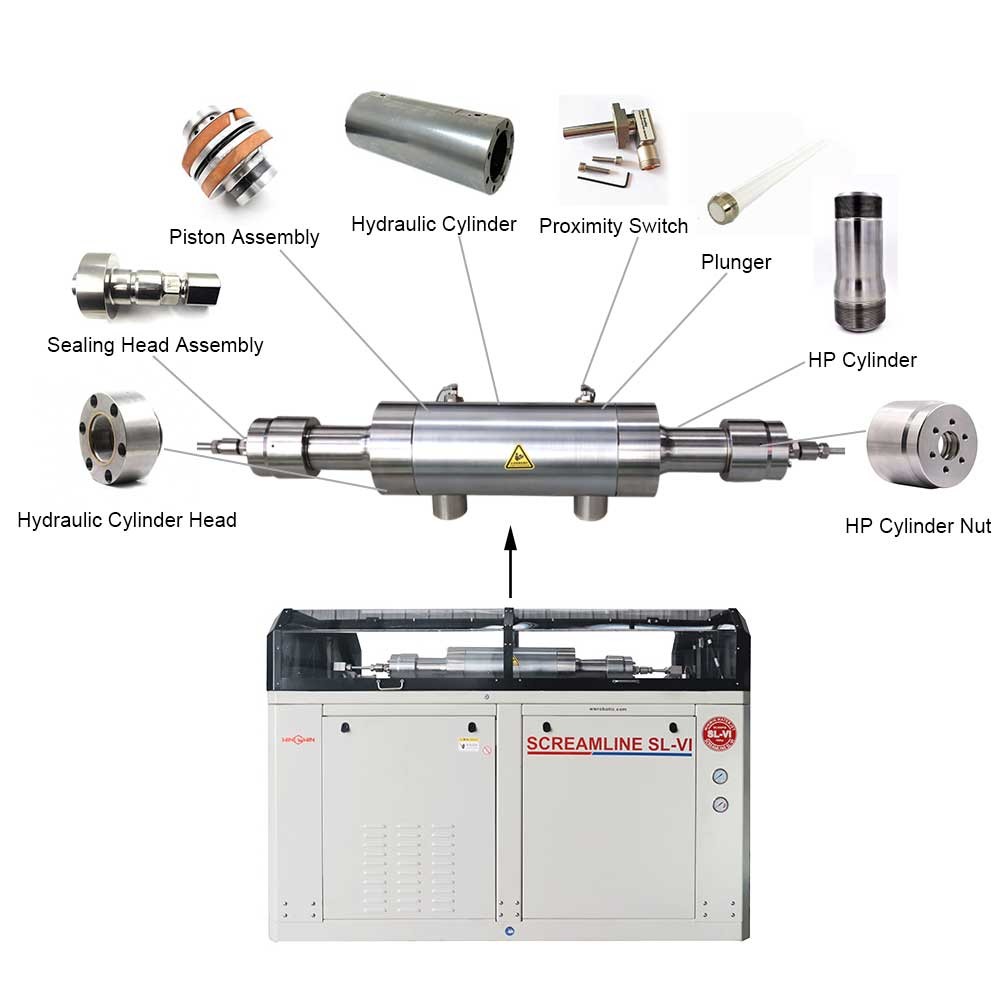

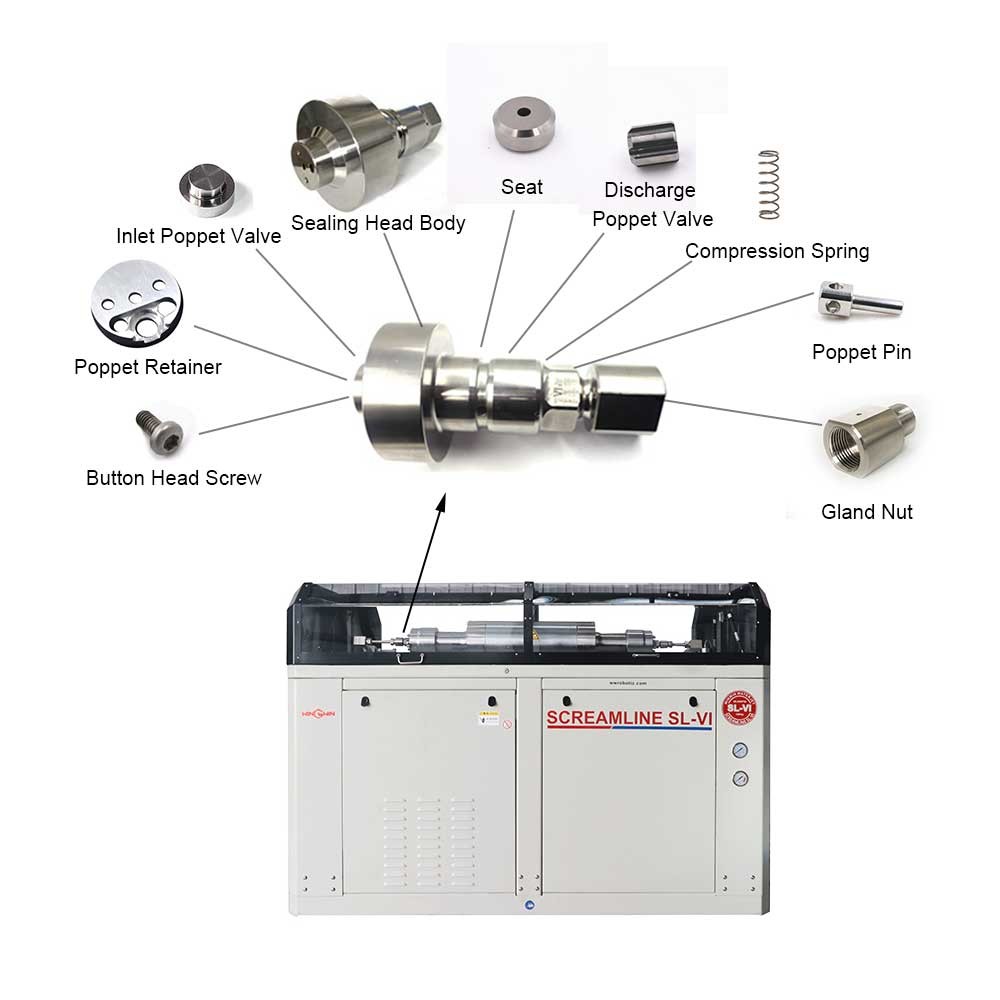

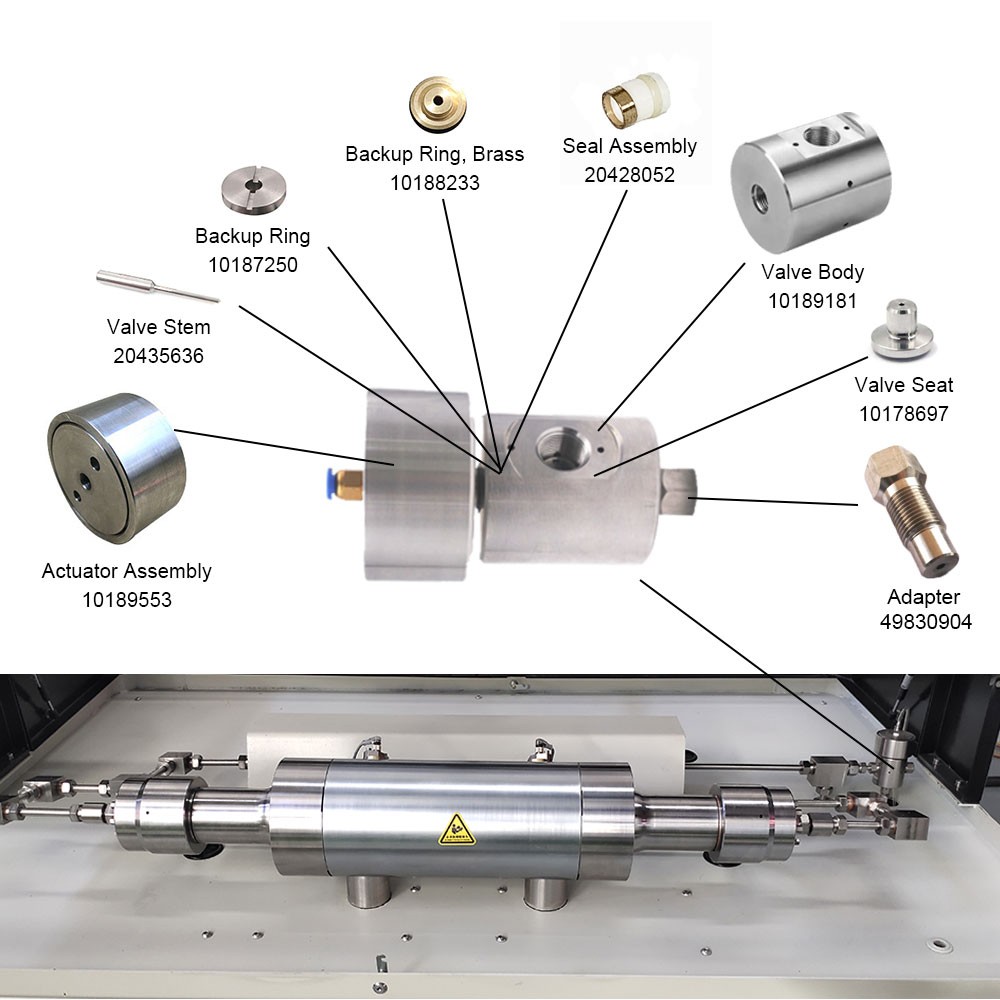

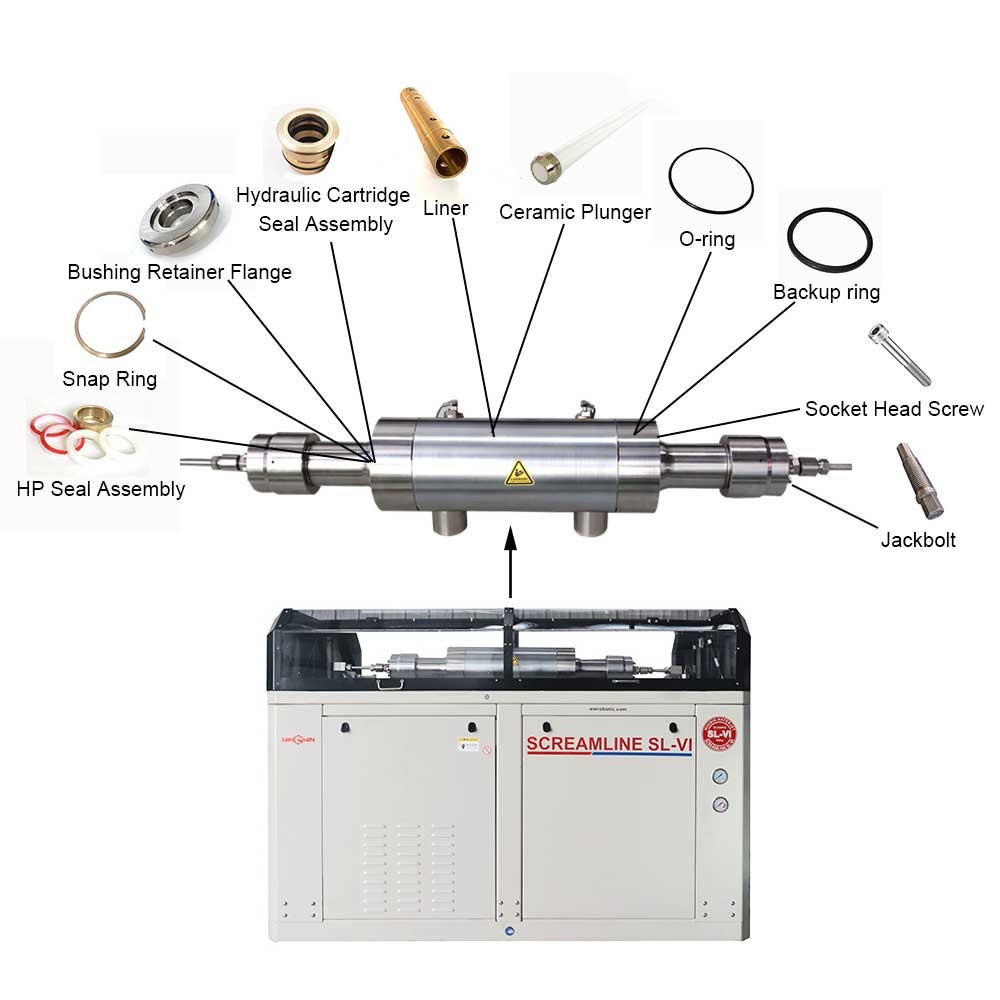

After the tap water is filtered by the filter, it is pressurized by the oil pressure system and enters the high-pressure cylinder at both ends of the intensifier. When the oil pressure system moves back and forth, the waterjet spare part high-pressure cylinder at one end enters the water through the waterjet spare part inlet check valve, and the water of the high-pressure cylinder at the other end is pushed out and enters the high-pressure pipeline through the water outlet check valve. This is repeated alternately in the high-pressure cylinders at both ends to form a continuous stream of high-pressure water jet. Due to the commutation cycle of intensifier, the pressure of output water flow fluctuates periodically. Therefore, the high-pressure water flow needs to be stabilized by the waterjet spare part high-pressure accumulator and transmitted to the nozzle through thewaterjet spare part high-pressure tube. The pressure drop occurs at the moment of reversing the plunger of the intensifier. The plunger suddenly reverses during the pressurization process, and the high-pressure water loses momentum, and the pressurization chamber becomes pressureless.

At this time, the energy released by the accumulator closes the one-way valve. Because the nozzle aperture is very small, the energy of the jet is completely supplied by the accumulator. When the reversing of the waterjet spare part plunger of the intensifier is completed, the pressure generated by the intensifier offsets the release pressure of the accumulator, and the waterjet spare part one-way valve on the other side of the intensifier opens, At this time, the pressure continues to rise, and the accumulator is in the pressurized energy storage state. When the pressure generated by the intensifier and the pressure of the accumulator remain at the same level, the system pressure maintains balance, the pressure does not fluctuate, and continues to provide the high-pressure water required by the system. In order to save the operation cost, do not set the pressure in the high-pressure section all the time in the production process.

wwaterjet

wwaterjet