Principle of waterjet cutting servo driving system

Water jet cutting machine - servo drive system :The driving system is the power source of the water jet cutting machine with good waterjet spare parts, which will be directly related to the cutting capacity of the equipment. At present, most water jet cutting machines with good waterjet spare parts use the driving system based on the servo driving system. Of course, some equipment will use the stepping driving system. What kind of driving system is good for water cutting machine? We have to study it in depth. For water cutting machine, there is an obvious difference between servo drive system and stepping drive system.

This difference will first be reflected in the control accuracy. Because the stepping motor is an executive element in the digital control system, it can transform the pulse electrical signal into the corresponding angular displacement, and the amount of angular displacement is directly proportional to the number of pulses, and the speed is directly proportional to the pulse frequency, so that it can adjust the speed by changing the pulse frequency in a wide range. The servo motor is an executive file that quickly converts the control electrical signal into the rotation of the rotating shaft. If the control electrical signal is added to the motor, the servo motor will immediately drive the load to rotate at a certain speed. The AC servo motor does not have such a problem, which can ensure the stability of the water jet cutting machine with good waterjet spare parts.

The ultra-high pressure water jet cutter adopts servo motor as the driving element, which can not only execute the motion command well, but also will not lose step because it belongs to closed-loop control. While ensuring the synchronization of the input pulses of the servo motor, the required rotation angle, speed and rotation direction can be obtained only by controlling the number, frequency and direction of the input pulses.

Composition of robot waterjet cutting

Waterjet cutting is suitable for cutting various materials (such as glass, marble, leather, plastic, steel plate, automobile interior parts, etc.). It can accurately cut complex workpieces with free-form surfaces. It is used in automobile internal and external accessories, aircraft manufacturing, building materials and clothing industries. It can greatly improve the cutting quality and production efficiency of workpieces, and is suitable for the processing of various products. Compared with impact forming, it can greatly save the cost of die development. It can also reduce labor intensity and make workers get rid of heavy labor.

The whole robot waterjet cutting system consists of :

Robot arm system

We provide different robot brands such as:ABB,YASKAWA,FANU. Different robot arm model can fit pedestal type structure or ceilling type structure.

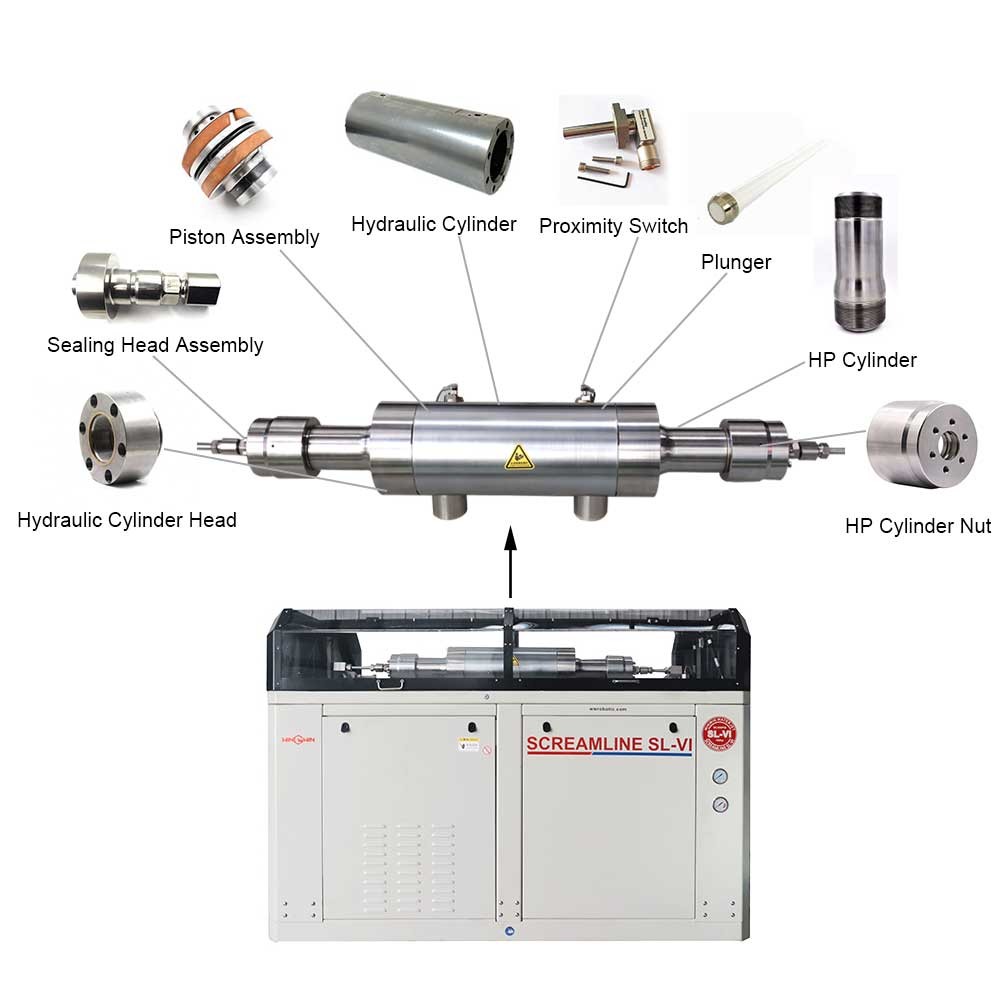

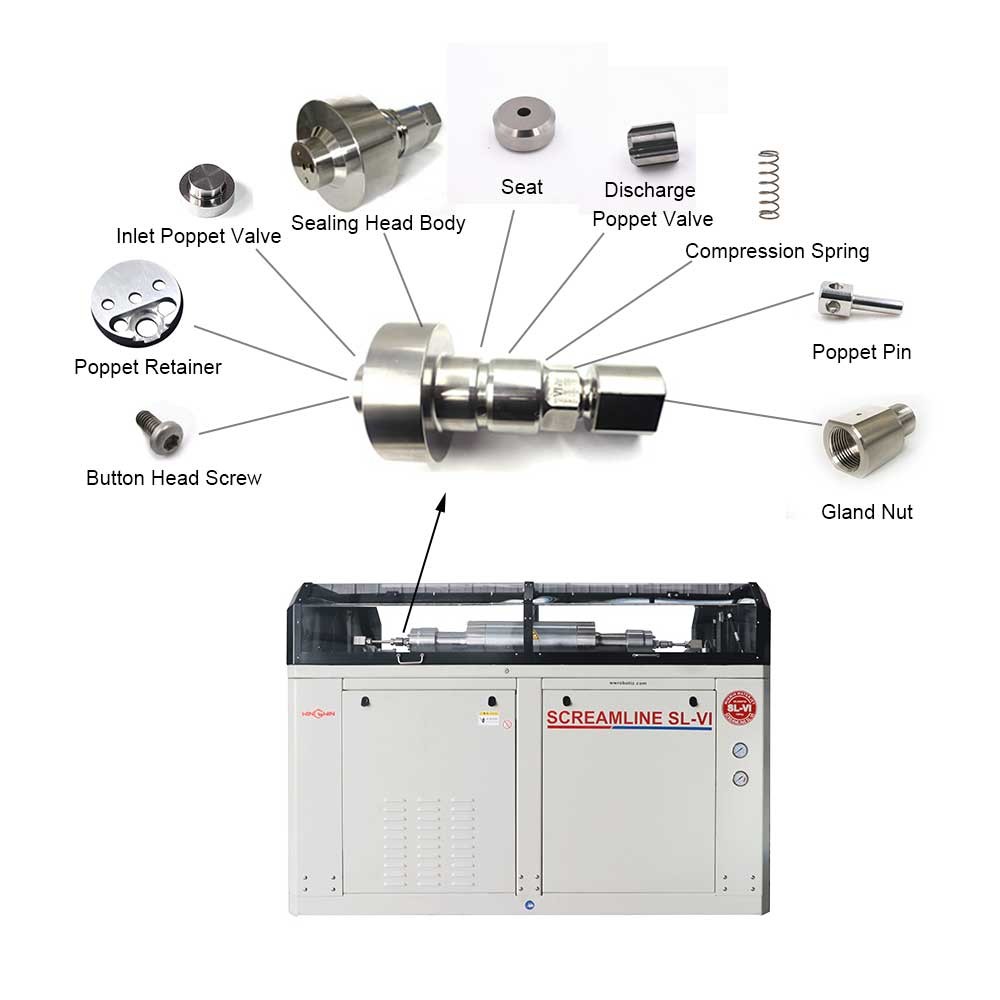

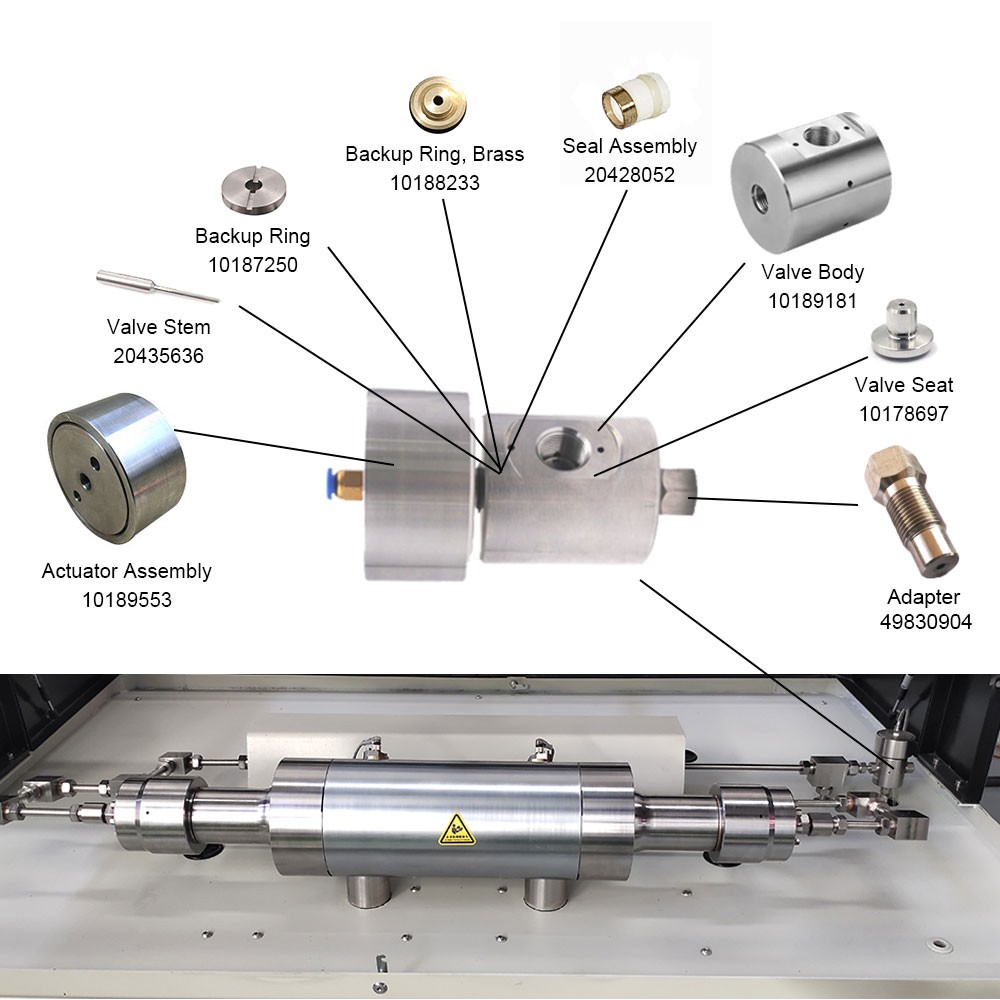

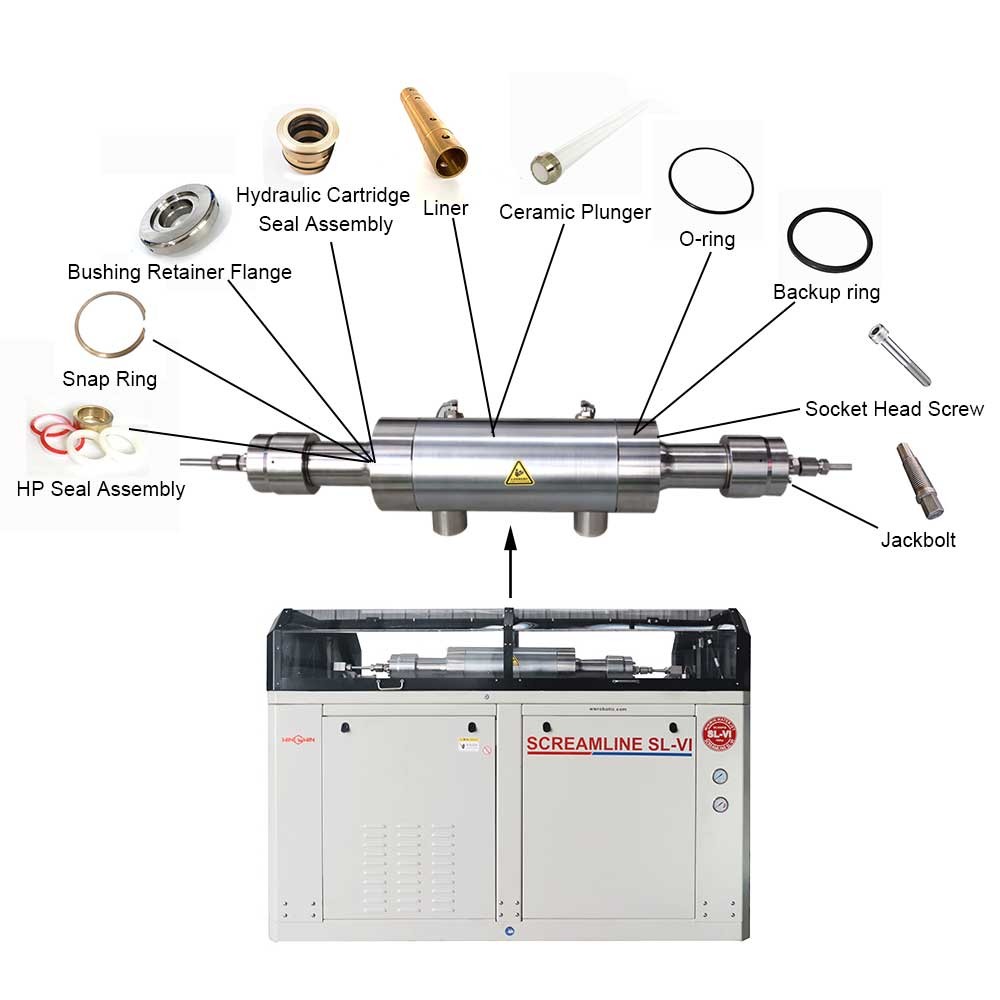

Intensifier pump

Intensifier pump is the equipment that boosts the low pressure water jet to the ultra high pressure water jet, which is the key to cutting, it is the power source for water cutting, and the high and low levels of boosting directly determine the cutting efficiency, and the waterjet spare parts and intensifier pump are the core part of water jet cutting, so it is essential to maintain and maintain the intensifier pump.

Cooling system

The cooling system was able to cool the oil temperature at the water temperature of the machine, so that the temperature was at a stable level, maintaining a stable operation of waterjet cutting.

Suction system

The vacuum adsorption system is capable of adsorbing excess material under cutting in the working platform, relying on strong adsorption forces, and can adsorb excess material, which is beneficial for centralized cleanup

Water softening system

The ability of water softening system is to purify impurities and calcified substances from pure water is beneficial to extend the life of every spare partsand improve waterjet cutting accuracy.

The application

It is suitable for high-pressure water cutting of various materials (such as glass, marble, leather, plastic, steel plate, automobile interior parts, etc.), and can accurately cut and process complex workpieces with free-form surface. Using robots to cut and process workpieces with various complex shapes has been widely used in automobile interior and exterior trim parts, aircraft manufacturing, building materials and clothing industries abroad. It can greatly improve the cutting quality and production efficiency of workpieces, and is suitable for the processing of many kinds of products. Compared with impact molding, it can greatly save the cost of mold development, reduce the labor intensity and free workers from complicated labor.

For all of these, the most important thing is waterjet spare parts, as waterjet spare parts are an important component of the entire water cutting system. The quality of waterjet spare parts determines the service life of the entire system. Our company can provide different brands of waterjet spare parts for you to choose from and adapt to your booster pump. High quality and versatile waterjet spare parts can perfectly solve your water jet cutting problems.

wwaterjet

wwaterjet