Waterjet spare parts are an important component of intensifier pumps, and they are also vulnerable parts. Regular maintenance and upkeep are crucial. If there is no regular repair and maintenance of wateraterjet spare parts, it will cause downtime and unnecessary losses. Similarly, when assembling the intensifier pump, we also need to pay attention to many technical requirements to pursue, such as site, environment, and quality of waterjet spare parts.

Requirements for water jet intensifier pump

Before the installation and commissioning of water jet intensifier pump, it should meet the following requirements

Site requirements

1. The ambient temperature range of the equipment plant is 10 ℃ - 30 ℃, and the relative humidity is 40% - 75% RH.

2. Storage ambient temperature: - 10 ℃ - 50 ℃.

3. The atmospheric pressure is 86kpa-106kpa, the dust concentration in the air shall not be greater than 10mg / m3, and shall not contain acid, salt and corrosive gas.

4. The equipment shall be far away from the source, heat source, interference source and heat flow. The vibration in the workshop shall be less than 0.5g (G is the gravitational acceleration).

5. The material of the ground must be able to bear the weight of the machine and be thick enough to resist the vibration of the machine.

6. At least 900mm clearance shall be reserved on each side of it for maintenance.

Warning:

1. The water jet intensifier pump shall not be installed in the environment with the temperature below zero. If the freezing point is expected in the next operation, drain the water in the water pipe and filter on the day after the equipment works and it can damage the waterjet spare parts in the same time.

2. If the waterjet spare parts abrasive pipe and valve are frozen, do not operate the equipment. The system must be completely thawed until the water can flow freely in the system.

Power requirements

1. Three phase five wire system, 380V, 50Hz. A12x2 power supply line shall be 35 mm2 × 3+1 × 10 mm2, grounded with another 10 mm2 wire. The cable shall enter the distribution box of EHV generator from the inlet hole of power line.

2. There must be good grounding, and the zero line and ground line shall be strictly distinguished.

3. The stable value of input power supply voltage is ± 5% of rated voltage.

4. The input power frequency is ± 1% of the rated frequency.

5. (A12 A12 + B 09A A10) total capacity of power supply: 38KW (380MPa), total capacity of a12x2 power supply: 76kw.

Warning:

1. The power supply and remote control wiring used by the ultra-high voltage generator must comply with the local electrical code, local electrical code and national electrical code.

2. The working voltage and ampere capacity must meet relevant requirements.

The above related contents are also reflected in the installation overview of water jet pump and waterjet spare parts.

Hydraulic oil requirements

The power medium of water jet intensifier pump is hydraulic oil. Just like the safe operation and maintenance of the water knife, the correct selection and use of hydraulic oil is the basic guarantee for the normal use of the equipment. Unreasonable application will cause major damage to equipment and personal injury.

1. 46 anti-wear hydraulic oil or anti-wear hydraulic oil of the same grade shall be used. Please use mineral oil series anti-wear hydraulic oil. The dosage is 100L.

2. Before filling the oil tank, the anti-wear hydraulic oil shall be filtered, and the filtering accuracy shall not be less than 25 μ m.

Water requirements

1. The water jet intensifier pump needs two incoming water sources (cooling water and cutting water) and one drainage pipeline (cooling water). All waterjet spare part pipelines must comply with relevant local specifications, local specifications and national specifications.

2.Before pipeline connection, all supply waterjet spare partfittings shall be thoroughly cleaned to clean the residues that may pollute the system.

All waterjet spare part joints shall be equipped with manual shut-off valves. In order to facilitate maintenance, the installation position of manual shut-off valve shall be as close to the interface connector as possible.

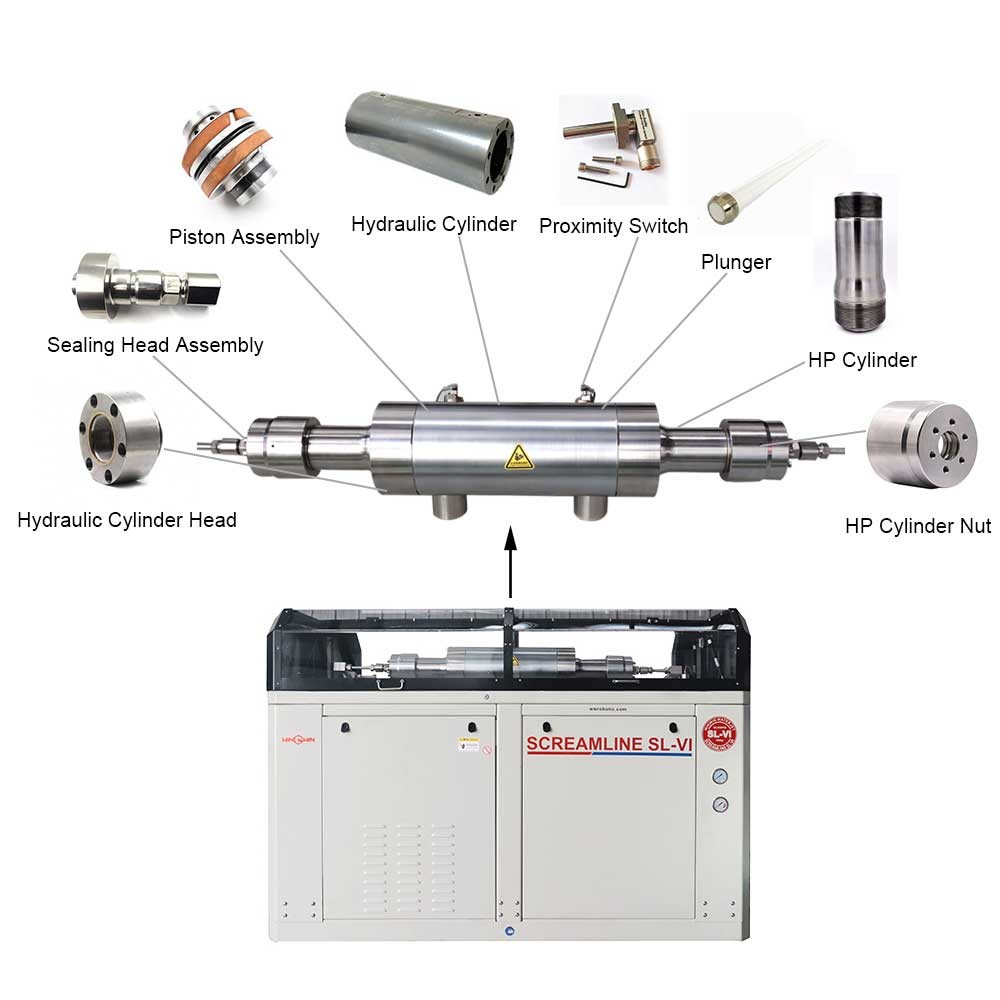

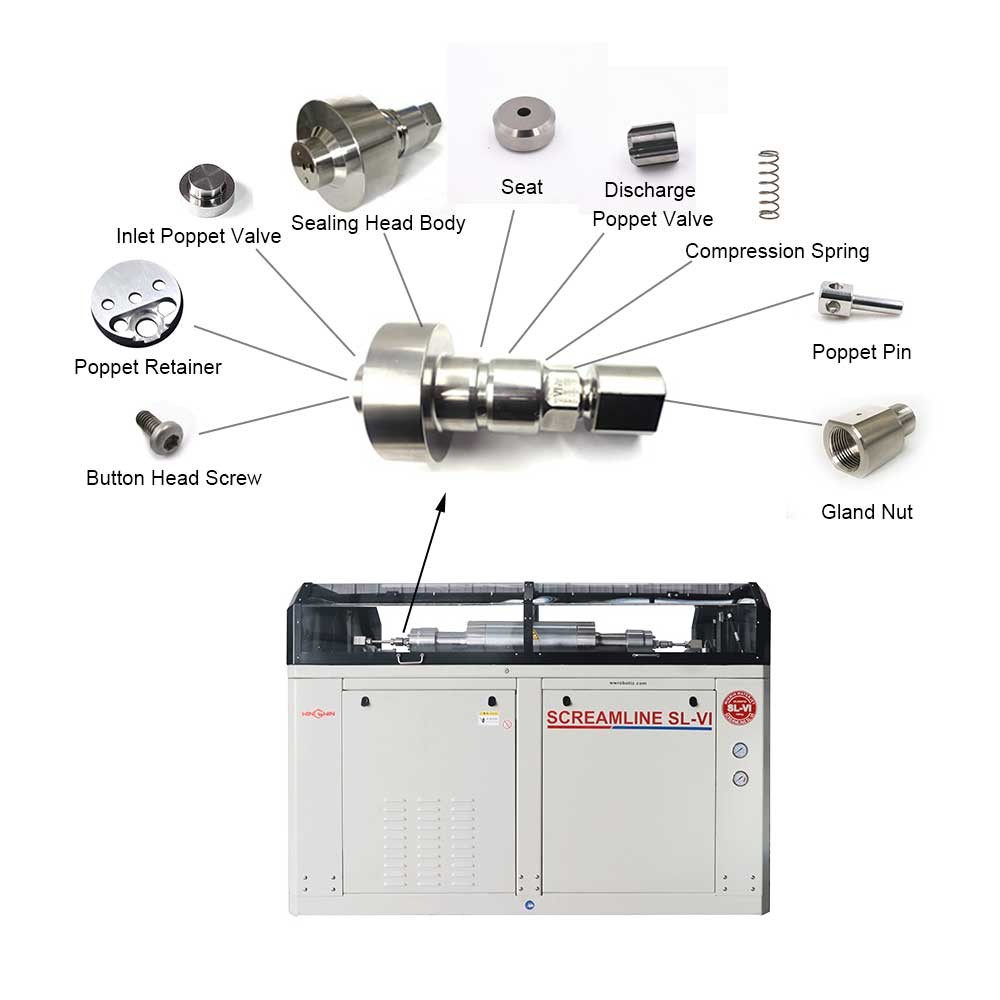

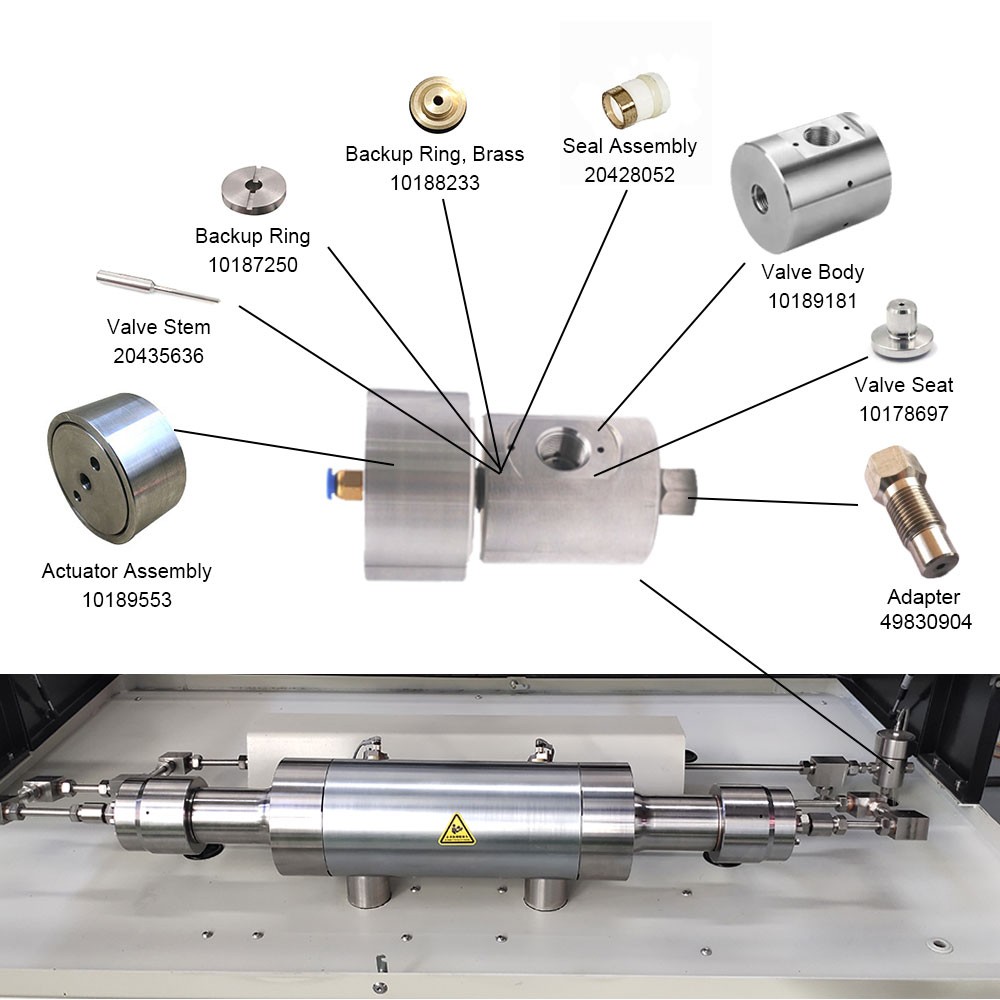

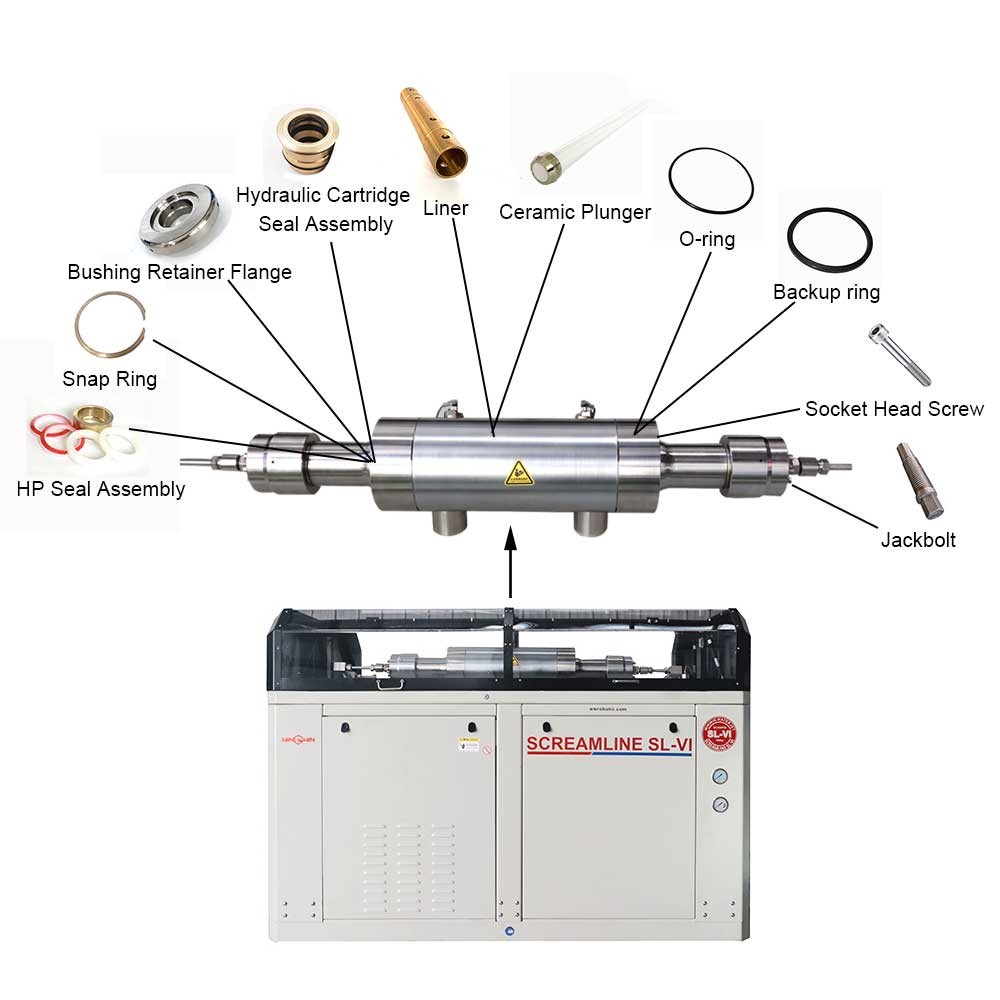

Intensifier pumps are indispensable components of ultra-high pressure water jet cutting machine, so the design and selection of these two parts should be more careful. If there is any deviation, it will affect the working performance of the cutting machine and cannot complete various cutting tasks. The gantry structure with movable worktable, which is often used in ultra-high pressure water jet cutting machine with waterjet spare parts, is mainly composed of left and right base frames and beams, table frame and rotating fixture, driving elements, transmission system, guide rail, protective cover and other parts. The left and right foundations are frame structure, which has good stress state, good bending resistance and seismic performance; The cross beam is a box structure, with both ends supported on the guide rail and moving along the guide rail, which plays the role of fixing the nozzle, adjusting the target distance, controlling the plane movement of the waterjet spare part nozzle and so on.

wwaterjet

wwaterjet