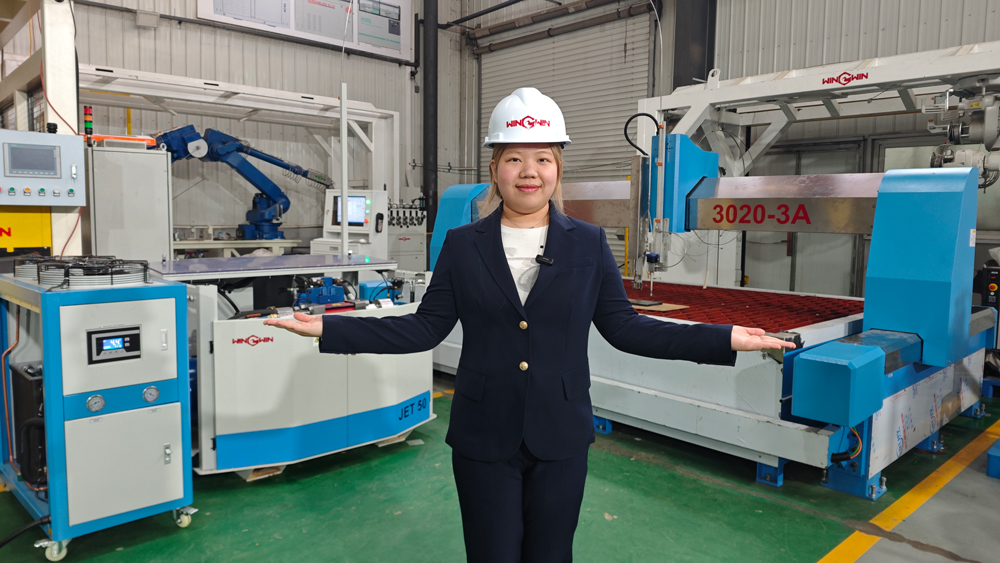

Recently, Winwin officially launched the new 3020 3-axis waterjet pure machine. As a core equipment focusing on high-precision cutting, this waterjet pure machine has achieved a major breakthrough in cutting effect with the support of Winwin's core technology. With smooth and flat cutting edges and precise dimension control, it provides a top-tier solution for the precision processing needs of various industries such as electronics, aerospace, and medical devices, attracting widespread attention in the industry.

The core advantage of Winwin 3020 3-axis waterjet pure machine lies in its excellent cutting effect. To achieve the ultimate cutting quality, the equipment is equipped with Winwin's independently developed high-precision 3-axis linkage control system, combined with imported high-precision linear guides and servo drive systems. It not only has a positioning accuracy of up to ±0.01mm, but also ensures the smoothness of the cutting trajectory. Whether it is ultra-thin electronic films, extremely brittle ceramic materials, or high-demand precision alloy parts, the equipment can handle them easily. After cutting, the edge is smooth and flat, burr-free and free of thermal deformation, eliminating the need for subsequent secondary grinding and processing, and completely solving the pain points of rough edges and large dimensional deviations of traditional cutting equipment. While ensuring top-level cutting effect, the cutting efficiency of the equipment is also outstanding. Equipped with a high-power high-pressure water pump, the maximum water supply pressure can reach 400MPa, and the cutting speed is increased by more than 30% compared with similar equipment, achieving a dual breakthrough in cutting quality and efficiency.

As a professional waterjet pure machine, it adopts pure physical pure water cutting technology without adding any abrasives. This fundamentally avoids the wear and pollution of the cutting edge by abrasives, further ensuring the cleanliness and flatness of the cutting surface. This advantage is particularly crucial in industries with high requirements for material purity such as medical devices and precision electronics. In addition, the equipment's workbench size is 3000mm × 2000mm, which can meet the batch cutting needs of small and medium-sized workpieces. Equipped with Winwin's intelligent control system, it is simple and convenient to operate, and even new operators can master it quickly. While ensuring stable cutting effect, it effectively reduces the labor cost of enterprises.

With its excellent cutting effect, Winwin 3020 3-axis waterjet pure machine has shown strong adaptability in multi-industry applications. In the electronics industry, it can accurately complete the cutting and forming of precision circuit boards and electronic components, with smooth and undamaged edges to ensure the stable performance of electronic components. In the aerospace field, it can perform high-precision cutting of light alloy materials, with high fit of the cutting surface, meeting the strict standards of aerospace components. In the medical device industry, it can achieve pollution-free and high-precision processing effects for the cutting needs of medical stainless steel, ceramics and other materials, providing a strong guarantee for the safety of medical equipment. At present, the equipment has passed a number of authoritative industry tests, and its core performance indicators such as cutting precision and cutting edge quality have reached the international advanced level.

A relevant person in charge of Winwin said that the core R&D focus of the 3020 3-axis waterjet pure machine is to optimize the cutting effect, which is also the result of Winwin's years of technical precipitation in the field of precision cutting. In the future, Winwin will continue to be market-oriented, continuously iterate the relevant technologies of waterjet pure machine, launch more high-quality equipment with excellent cutting performance, and help the high-quality development of the global precision manufacturing industry.

If you are interested in, contact us.

wwaterjet

wwaterjet