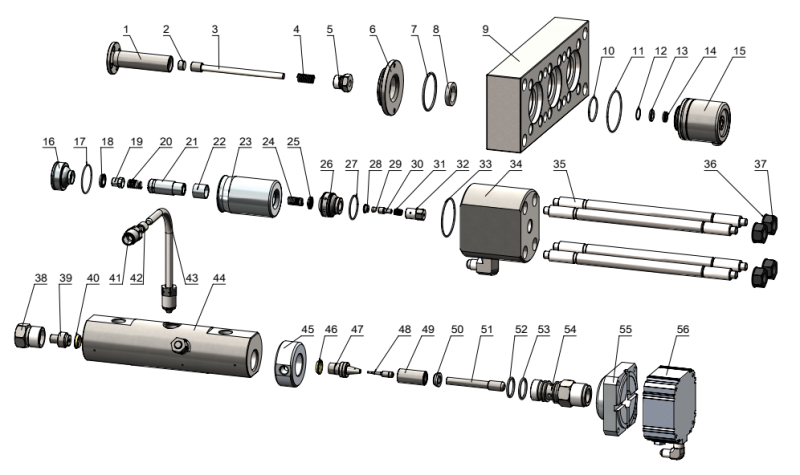

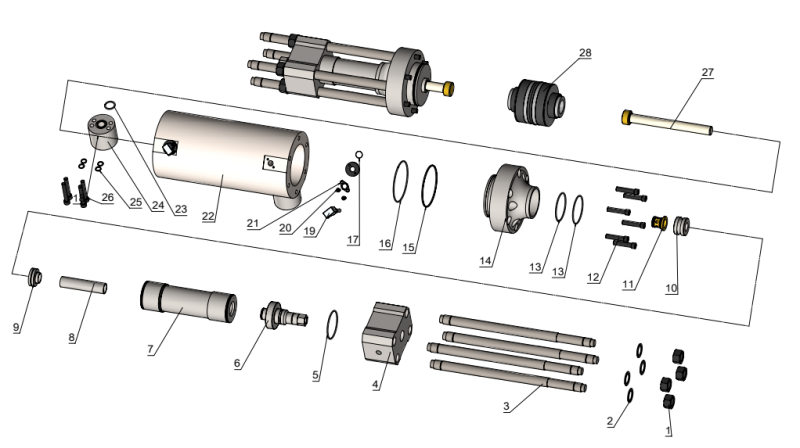

Waterjet Parts 012402-1 Direct Drive pump Subplate Adapter Assembly

Direct Drive pump 012402-1 Subplate Adapter Assembly

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

Waterjet direct drive pumps are generally more efficient than other types of high-pressure pumps used in waterjet cutting applications, such as intensifier pumps.

One reason for this is that the direct drive design eliminates the need for a gearbox or transmission system, which can introduce energy losses due to friction and other inefficiencies. By connecting the motor directly to the plunger or piston, the direct drive pump can deliver power to the water more efficiently, resulting in less waste heat and higher overall efficiency.

In addition, because direct drive pumps typically operate at a lower RPM than intensifier pumps, they can also be more efficient in terms of mechanical losses. This is because lower RPMs generally result in less friction and wear on the pump components, which can improve longevity and reduce maintenance requirements.

while there are many factors that can influence the efficiency of a waterjet cutting system, a waterjet direct drive pump can be a good choice for applications where high efficiency and reliability are important.

Waterjet direct drive pumps are typically more efficient than intensifier pumps, which are another commonly used type of high-pressure pump in waterjet cutting applications. Intensifier pumps use a hydraulic system to increase the pressure of the water, while direct drive pumps use a mechanical system to achieve the same result.

One advantage of direct drive pumps is that they can be more reliable and require less maintenance than intensifier pumps. This is because intensifier pumps have more components, such as hydraulic cylinders and pistons, that can wear out over time and require maintenance. In contrast, direct drive pumps have a simpler design with fewer components, which can make them less prone to failure and easier to maintain.

Another advantage of direct drive pumps is that they can be more precise and accurate in controlling the pressure and flow of the water. This is because direct drive pumps can respond more quickly to changes in the cutting conditions, which can help to maintain consistent cutting quality and reduce waste.

However, it's worth noting that direct drive pumps can be more expensive than intensifier pumps, especially for high-pressure applications. In addition, direct drive pumps may require more electricity to operate than intensifier pumps, which can increase operating costs.

Overall, when choosing a waterjet cutting system, it's important to consider a range of factors, including efficiency, reliability, precision, and cost. A waterjet direct drive pump can be a good choice for applications where high efficiency and reliability are important, but it's important to evaluate all of the available options and choose the one that best meets your specific needs.

If you are interesting in other Direct drive pump parts,please contact when you free.

wwaterjet

wwaterjet