Skills for water jet maintenance

As an efficient cutting machine, water jet still has many problems, and water jet and waterjet accessories maintenance is also a science. If it is not well mastered, it will not only not solve the problem, but may also cause new problems, which is very unfavorable for water jet . The following are some water jet maintenance skills after routine problems occur, mainly including 4 aspects.

1. Water in water jet maintenance

The main working medium of the water jet is water, which can be fully utilized after the cutting work is completed, so as not to cause waste and increase costs. But I want to remind everyone that there is a prerequisite for the reuse of water, and it must be re-filtered and meet the quality standards.

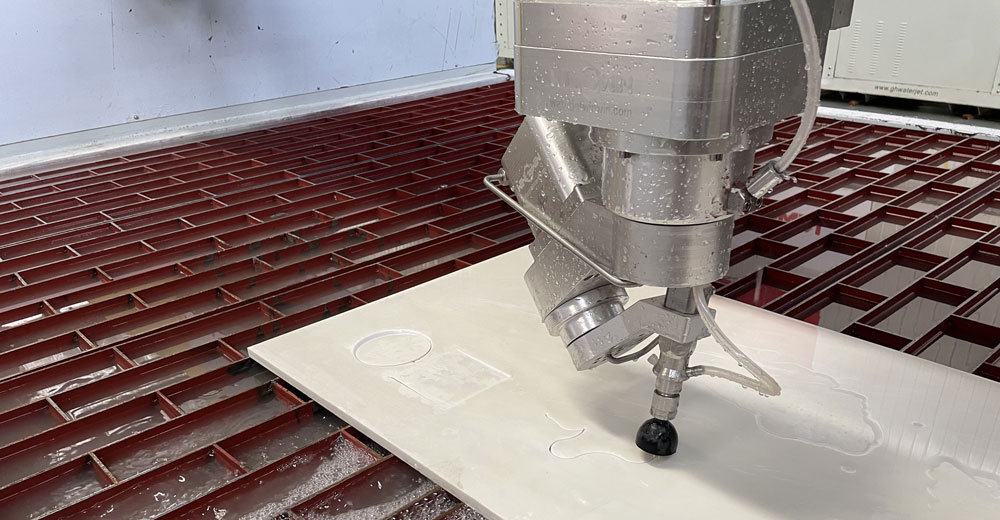

2.Waterjet accessories abrasive nozzle and abrasive garnet in water jet maintenance

The waterjet accessories nozzle tube equipped on the water jet has a certain service life. It can neither be replaced prematurely nor used all the time, which will affect the precision and accuracy of cutting. Since the service life of the waterjet accessories nozzle tube is related to many factors, such as the method of use, installation skills, type of abrasive sand and its own quality, etc., the replacement cycle can only be determined after comprehensive consideration.

Waterjet cutting is very popular as a common processing method. In this process, water jet as a comprehensive whole needs the cooperation of various parts in order to achieve the best use effect. Among them, the quality of waterjet accessories abrasive garnet is also extremely critical, especially in terms of cutting efficiency, which has a far-reaching impact.

In the case of low concentration of waterjet accessories abrasive garnet particles, the risk of plugging will gradually occur, which will greatly affect the cutting power and delay the progress of the project. Judging from the harmfulness of the above summary, waterjet sand as a consumable has a very important influence in the use, so it must be carefully selected.

3. The programming of water jet maintenance

Don’t think that such a professional programming problem is definitely difficult to achieve. In fact, the current water jets all use CNC numerical control system. The programming of the program can be completed by NEWCAM software. In the end, it is only necessary to directly convert the DXF file into a cutting program. That's it.

4. Solving the problem of excessive pressure in water jet maintenance

Many users worry that once the pressure inside the equipment is too high, it will cause a series of adverse phenomena, and even cause the danger of explosion. In fact, such worries are completely unnecessary, because all high-pressure parts and components in the water jet are carefully designed. Moreover, there is a safety hole inside the machine, even if the pressure is really too high, it will be safely depressurized and will not cause danger.

The function of each automatic valve of the water cutting machine

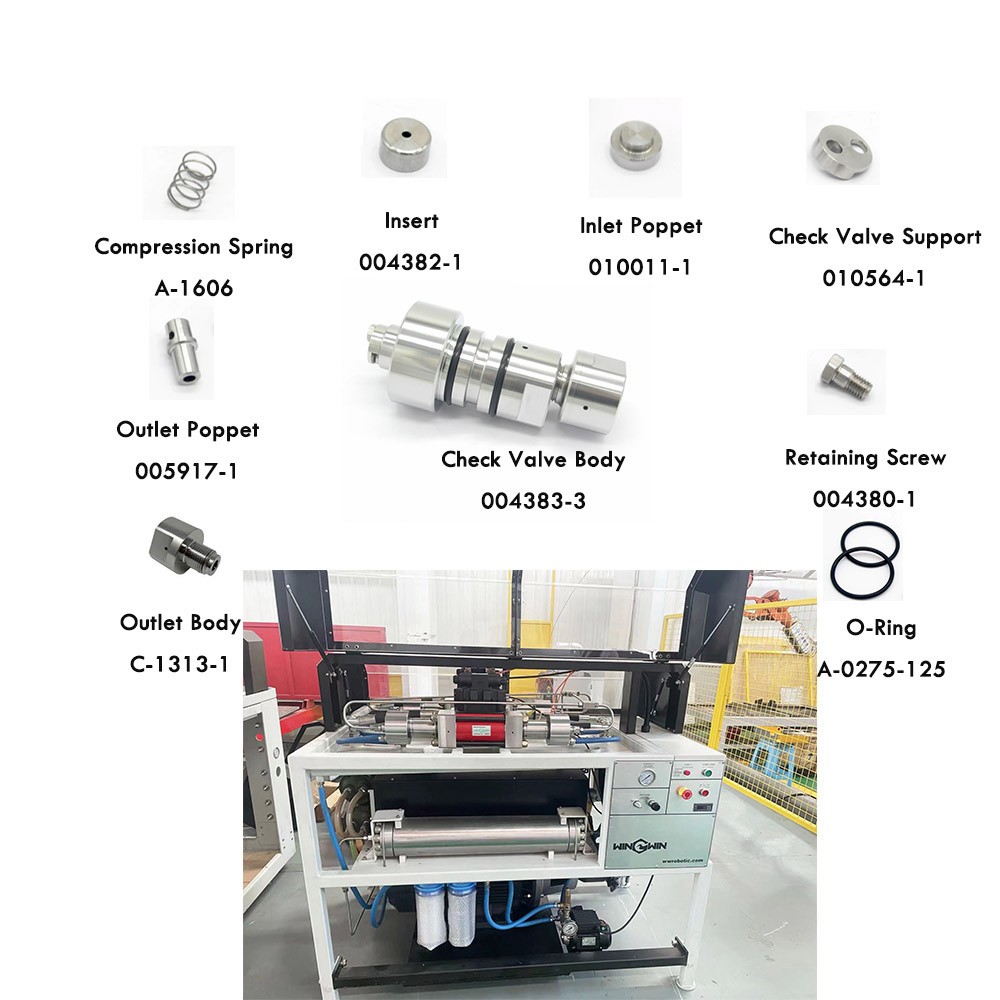

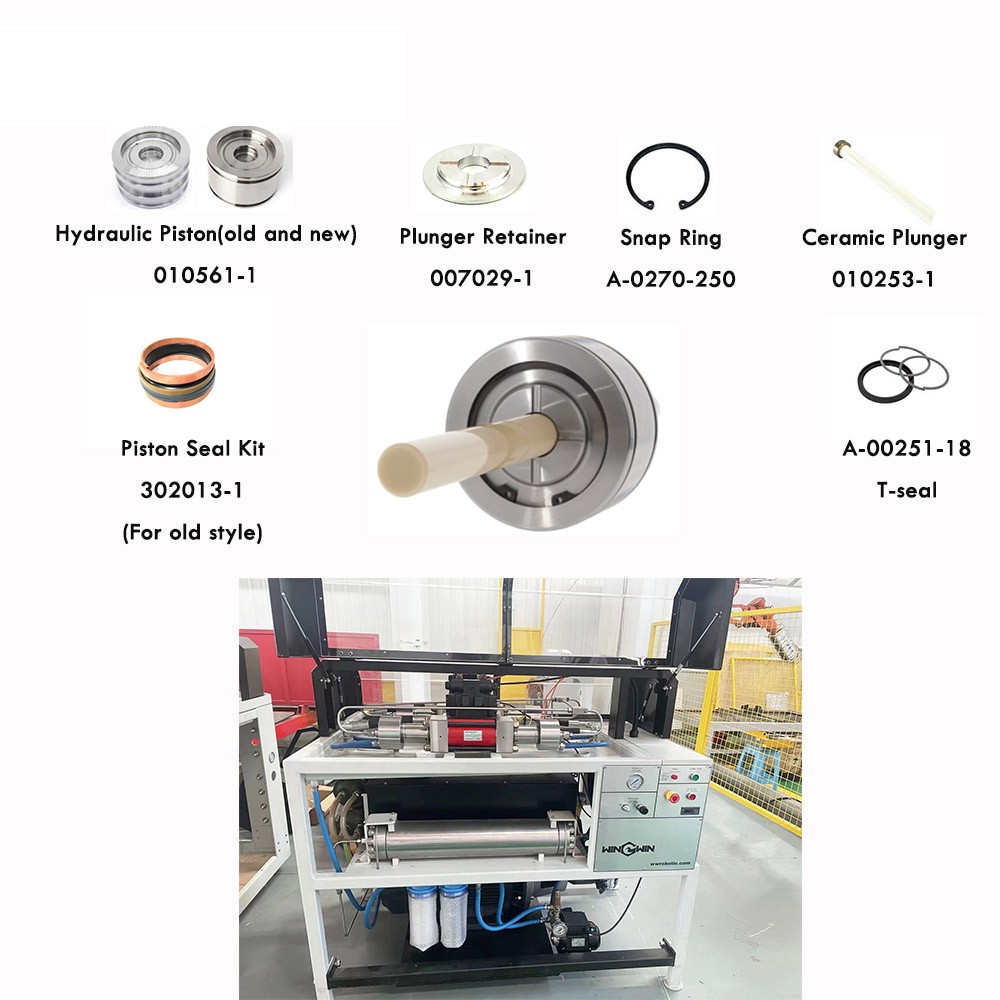

Like other equipment, the water jet cutting machine with good waterjet accessories is also equipped with many waterjet accessories valves, such as safety valves, pressure reducing valves, relief valves, etc., and these are all automatic valves. That is to say, they are valves that can control and adjust the pressure of the medium flow by relying on diaphragms, springs, pistons, weights and other components, by setting the results of the comparison between the pressure of the water jet cutting system and the pressure of the waterjet accessories.

Among them, the safety valve is a valve that prevents the pressure in the cutting machine system from exceeding the predetermined safety value. It opens the opening and closing member through the pressure of the medium itself, and discharges the excess medium flow from the system to protect the pipeline system. When the pressure returns to a safe value, the valve will close itself to prevent the medium from continuing to flow out, which is a protective device. Once the safety valve is activated, it means that there is a fault inside the water jet machine.

The pressure reducing valve reduces the inlet pressure to the required outlet pressure, so that the outlet pressure is automatically kept constant, and the medium flow of the pressure reducing valve always flows forward in the system. The overflow valve is to discharge the excess medium in the system from the high pressure part of the water jet cutting machine system and return it to the low pressure part of the system when the medium flow is overpressured, so as to keep the pressure of the waterjet accessories pipeline system stable. So in order to reduce the downtime dof your waterjet cutting machine, please choose WIN-WIN waterjet accessories. We have many waterjet accessories brands that you can choose to fit in your waterjet cutting machine.

wwaterjet

wwaterjet