Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

WJ055009/025 holder for BFT waterjet

Performing regular maintenance tasks on your waterjet cutting system can help prevent high-pressure seal damage and ensure that the system is operating at peak performance. Here are some common maintenance tasks you can perform to prevent seal damage:

Use clean water: Use clean, filtered water in your waterjet cutting system to prevent the buildup of minerals and other impurities that can cause damage to the high-pressure seals. Change the filters on the system as recommended by the manufacturer to ensure that the water is properly filtered.

Monitor pressure levels:Regularly monitor the pressure levels of the waterjet cutting system and ensure that they are within the recommended range. Exceeding the recommended operating pressure can cause damage to the high-pressure seals and other components of the system.

Inspect hoses and fittings: Regularly inspect the hoses and fittings on the waterjet cutting system for signs of wear or damage. Replace any components that are worn or damaged to prevent leaks and other issues.

Lubricate moving parts: Some components of the waterjet cutting system, such as bearings and other moving parts, require lubrication to operate smoothly and prevent wear and damage. Follow the manufacturer's recommendations for lubrication and perform this task on a regular basis.

Keep the system clean: Regularly clean the waterjet cutting system, including the cutting head, to remove debris and other materials. This can prevent clogs and other issues that can cause damage to the high-pressure seals.

Replace high-pressure seals regularly: Regularly replace the high-pressure seals in the intensifier pump, as recommended by the manufacturer. This can help prevent damage to the seals and other components of the system, and ensure that the system is operating at peak performance.

Follow manufacturer's recommendations: Follow the manufacturer's recommendations for maintenance and care of the waterjet cutting system, including replacement schedules, operating procedures, and other recommendations.

Performing these maintenance tasks on a regular basis can help prevent high-pressure seal damage and extend the life of your waterjet cutting system. It is important to work with an experienced and knowledgeable technician to ensure that the system is properly maintained and any issues with the high-pressure seals are addressed promptly and effectively. Regular maintenance and proactive measures can help prevent damage to the high-pressure seals and ensure that your waterjet cutting system is operating at peak performance.

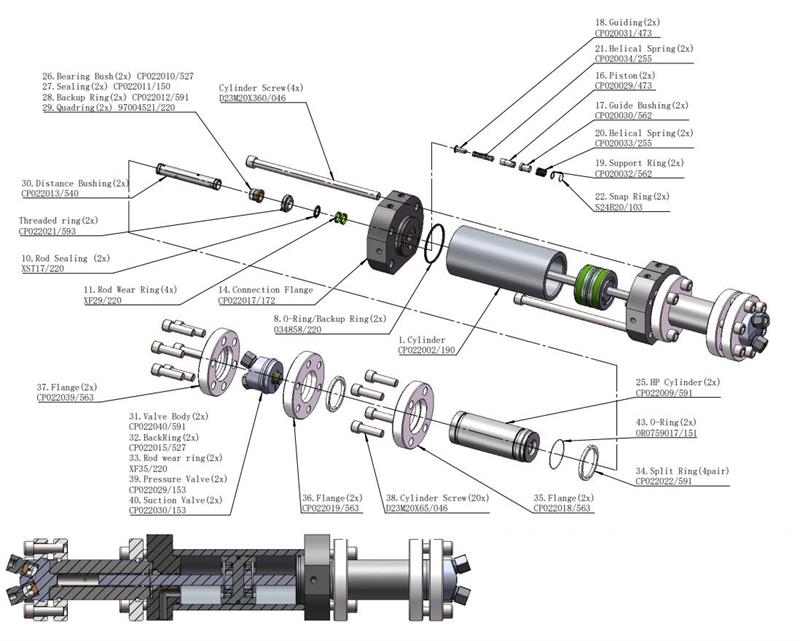

| CP022002/190 | Cylinder |

| 1200402 | piston complete |

| XK121/220 | Piston sealing |

| XF56/220 | Wear ring |

| CP022066/220 | Plunger complete |

| CP022057/075 | Clamp ring |

| HT022044/103 | Retaining ring |

| 034858/220 | O-ring backring 97 |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XF29/220 | Rod wear ring 22x27x5,6 mm |

| D23M20360/046 | Cylinder head screw |

| CP022017/172 | connection flange |

| CP022016/172 | connection flange |

| CP022021/593 | Thread ring |

| HT022004/473 | Piston |

| CP020030/562 | Bushing |

| CP020031/473 | Guiding |

| CP020032/562 | Supporting ring |

| CP020033/255 | helical spring |

| CP020034/255 | helical spring |

| CP020034/255 | Helical spring |

| S24B20/103 | Snap ring |

| xn5/220 | initiator |

| XST9/220 | PLUG |

| CP022009/779 | High pressure cylinder |

| CP022010/527 | Bearing bush |

| CP022011/150 | Sealing |

| CP022012/780 | Back ring |

| 9704521/220 | Quadring |

| CP022013/014 | Distance bushing |

| CP022040/591 | Valve body |

| CP022015/527 | Back ring |

| XF35/220 | Rod wear ring |

| CP022022/591 | SPLIT RING |

| CP022018/563 | Flange |

| CP022019/563 | Flange |

| CP022039/563 | Flange |

| D23M20*65/046 | Cylinder head screw |

| CP022047/844 | Pressure valve |

| CP022019/844 | suction valve |

| MA160818/220 | swivel male elbow |

| OR0759017/151 | o-ring75.92*1.78 |

wwaterjet

wwaterjet