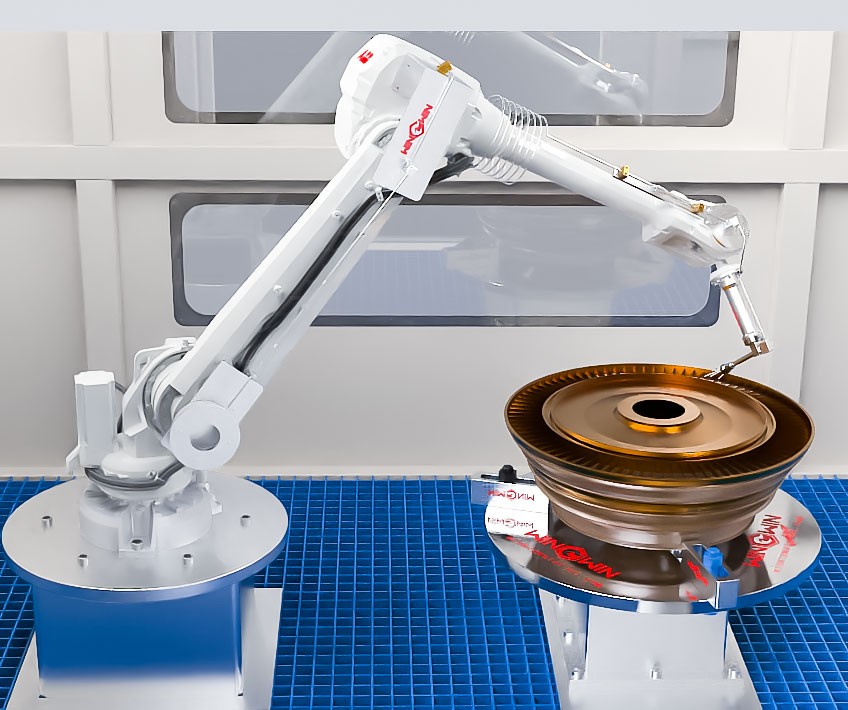

Ultra high-Pressure Waterjet Stripping

Stripping for MRO Aero Engines & IGT

Objective: Waterjet stripping is heavily adopted by OEMs and is an approved process in engine repair manuals for

removal of thermal spray coatings for aero-engine (commercial & military) as well as industrial gas turbines.

Use cases:

MRO (maintenance repair & overhaul):

after a given number of cycles (take-off and landing), turbines are fully dismantled and each coated component

is stripped to undergo inspection, repair & recoating.

Rework:

when an OEM (Original Equipment Manufacturer) sprays coating on a part and a fault is detected, the part is

stripped and the coating can be applied again.

Benefits:

Versatility: waterjet stripping removes all types of coatings from various base materials.

Efficiency: much higher removal rate compared to chemical and other methods.Improved part integrity &

increased number of repair cycles: no chemical or thermal impact to the part, no removal of the base

material (no stock-loss).

Eco-friendly: no chemicals used, only pure water which is recycled in close-loop

If you are interested in Ultra high pressure stripping, please feel free contact win-win waterjet

wwaterjet

wwaterjet