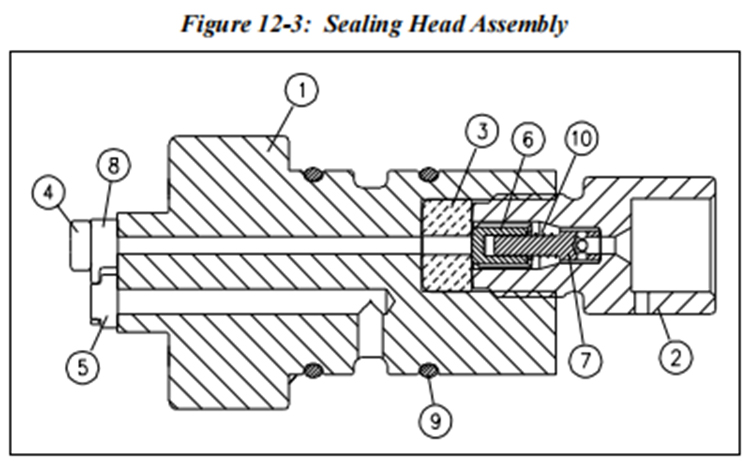

Table 12-3 Sealing Head Assembly 20458908 | |||

Item | Part Number | Description | Quantity |

1 | 20458098 | Body | 1 |

2 | 20457381 | Gland | 1 |

3 | 20458140 | Seat | 1 |

4 | 20458089 | Poppet Retainer Screw | 1 |

5 | 20457948 | Inlet Poppet | 1 |

6 | 20460048 | Discharge Poppet | 1 |

7 | 05116751 | Poppet Pin | 1 |

8 | 20458896 | Poppet Retainer | 1 |

9 | 80077241 | O-Ring | 2 |

10 | 20460033 | Compression Spring | 1 |

20458830 | Repair Kit Includes items 3, 4, 5, 6, 8, 9 and 10 | ||

The sealing head assembly in a waterjet system is a crucial component responsible for maintaining a watertight seal in high-pressure environments.

This assembly ensures that the water, typically pressurized up to 60,000 psi or higher, is properly directed through the nozzle without leaks,

which is essential for the efficiency and safety of the waterjet cutting process.

Key Components of a Waterjet Sealing Head Assembly

1. Seal Cartridge: Houses the seals and ensures a tight fit to prevent water leakage.

2. High-Pressure Seals: These are usually made of robust materials like polyurethane or other synthetic compounds to withstand high pressure.

3. Nozzle Assembly: Directs the pressurized water jet. It's typically made of tungsten carbide or sapphire to resist wear.

4. Gaskets and O-rings: Provide additional sealing and are often made from materials compatible with high-pressure water.

5. Mounting Hardware: Bolts, nuts, and washers used to secure the assembly in place.

6. Water Inlet Connector: Connects the high-pressure water supply to the sealing head assembly.

Maintenance Tips

Regular Inspection: Check for wear and tear on seals, gaskets, and nozzles regularly.

Seal Replacement: Replace seals at the first sign of wear to prevent leaks.

Proper Assembly: Ensure all components are correctly aligned and securely fastened.

Lubrication: Use appropriate lubricants to maintain the flexibility and integrity of the seals.

Cleanliness: Keep the assembly clean to prevent debris from damaging the seals and nozzles.

Troubleshooting Common Issues

Leaks: Check for worn-out seals or improperly tightened components.

Inconsistent Jet Stream: Ensure the nozzle is not worn or blocked and that the seals are intact.

Pressure Loss: Inspect the entire assembly for any loose connections or damaged seals.

Conclusion

The sealing head assembly in a waterjet system is a vital component that requires regular maintenance and inspection to ensure optimal performance.

Proper handling and timely replacement of wear parts will significantly extend the lifespan of the system and maintain its efficiency.

wwaterjet

wwaterjet