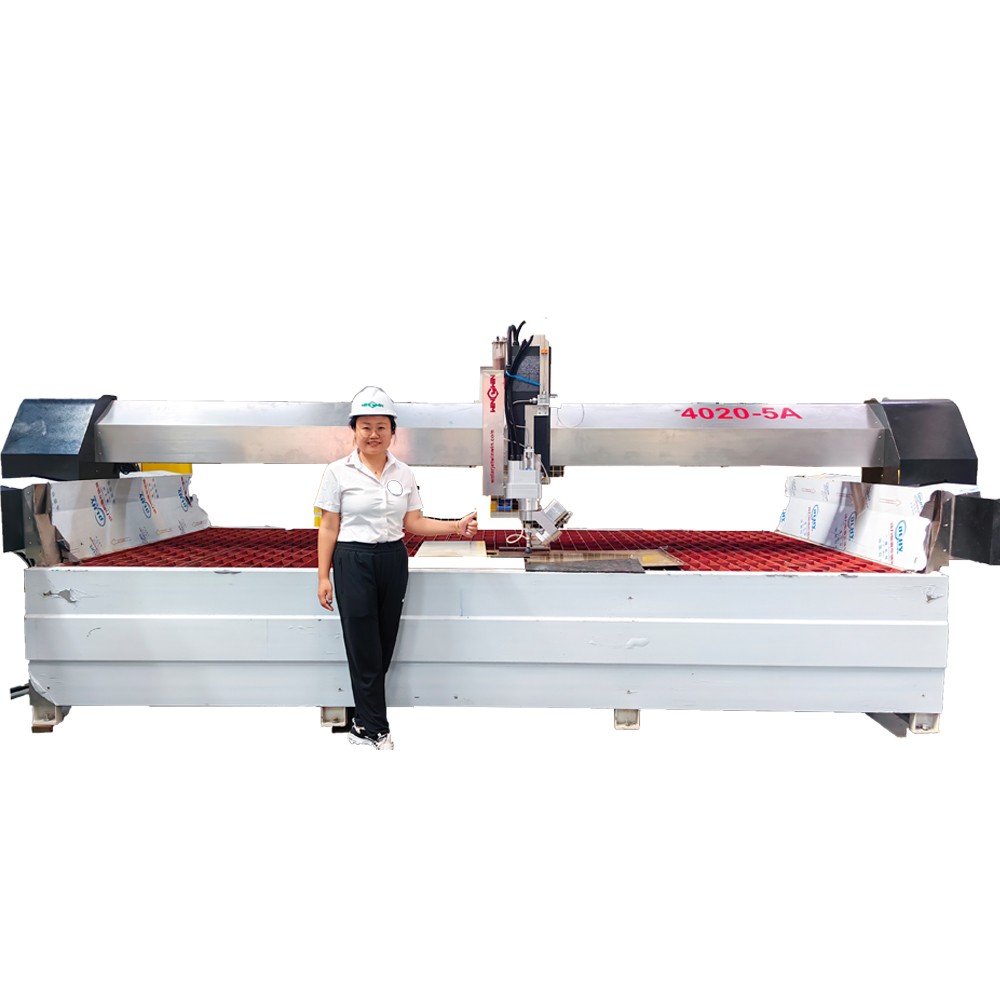

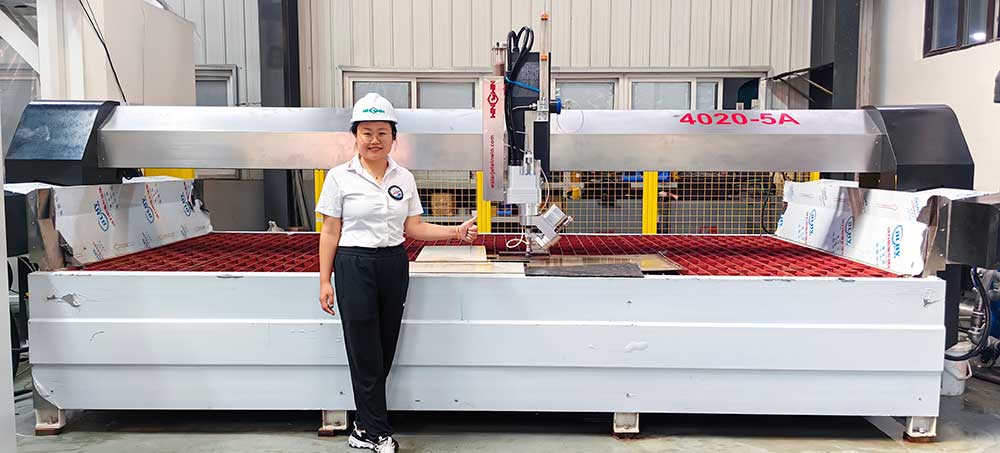

Polyethylene waterjet cutting 90000psi waterjet

Waterjet cutting is a versatile method used to cut a wide range of materials, including polyethylene.

When cutting polyethylene using a waterjet, there are a few considerations to keep in mind. Polyethylene is a

thermoplastic material, and waterjet cutting is a cold cutting process, meaning it does not create a heat-affected zone

in the material, which is beneficial for thermoplastics. Here are some general steps for waterjet cutting polyethylene:

Material Preparation:

Ensure the polyethylene sheet or block is securely fixed to the cutting bed to prevent movement during cutting.

Machine Setup:

Set up the waterjet cutting machine with the appropriate cutting parameters for polyethylenThis includes the cutting speed, abrasive flow rate (if abrasive cutting is used), and water pressure.

Cutting Parameters

Adjust the cutting parameters such as water pressure, nozzle size, and cutting speed based

on the thickness and type of polyethylene being cut.

Testing:

Before cutting the final part, it's a good practice to do a test cut on a small piece of polyethylene to

fine-tune the cutting parameters.

Cutting:

Start the cutting process, ensuring that the waterjet accurately follows the programmed cutting path.

Post-processing:

Once the cutting is complete, remove the cut polyethylene pieces from the cutting bed and clean

them if necessary.

Waterjet cutting is known for its precision and ability to cut complex shapes in various materials, including

polyethylene. When done correctly, it can produce high-quality cuts with minimal material waste.

wwaterjet

wwaterjet