Large Water Jet Cutting Ac 5axis Steel Abrasive Machines 315in x 157in

The WINWIN8040 excels in demanding, heavy industry environments. Cut large parts and heavy materials with ease, load and unload efficiently, add an additional gantry and multiple cutting heads to drive production to new levels.

Reduce cycle time with fast and nimble acceleration and deceleration. The WINWIN8040 cuts with astounding speed, driving overall part processing times down. Industry leading helical rack and pinion drive system ensures smooth motion across the table for accurate and precise cutting.

The WINWIN8040 is engineered for strength and speed, built with all-steel construction to handle heavy duty use 24/7. Engineered to order,.

With the WINWIN8040 you are guaranteed a total solution: complete with service, software, and cutting edge technology. WINWIN delivers more productivity and reliability with service solutions for parts, training, and preventative maintenance.

Large water jet machines offer several advantages, making them highly beneficial for various industrial and manufacturing applications:

Versatility: Water jet machines can cut a wide range of materials, including metals, composites, plastics, ceramics, stone, glass, and more. This versatility makes them suitable for diverse industries such as aerospace, automotive, construction, and manufacturing.

Precision: Water jet cutting provides high precision, with tolerances as tight as ±0.1 mm (±0.004 inches), depending on the material and thickness. This accuracy is crucial for industries requiring intricate designs and exact dimensions.

No Heat-Affected Zone: Unlike thermal cutting methods such as laser or plasma cutting, water jet cutting is a cold cutting process. It does not generate heat, preventing thermal distortion, hardening, or changes in material properties near the cut edge. This is particularly advantageous for materials sensitive to heat, such as plastics and heat-treated metals.

No HAZ (Heat-Affected Zone) Recast: Water jet cutting does not create a heat-affected zone or recast layer, which can occur with other cutting methods like laser or plasma cutting. This results in cleaner edges and reduces the need for secondary finishing operations.

Minimal Material Waste: Water jet cutting is a highly efficient process that minimizes material waste. The narrow kerf (cutting width) and ability to nest parts closely together optimize material usage, reducing scrap and improving overall material utilization.

Environmentally Friendly: Water jet cutting is considered environmentally friendly compared to other cutting methods. It uses water and garnet abrasive, which are non-toxic and recyclable. The process produces no harmful fumes, gases, or dust, contributing to a safer and cleaner working environment.

Ability to Cut Thick Materials: Water jet machines can cut thick materials, ranging from a few millimeters to several inches, depending on the material type and machine specifications. This capability is particularly useful for industries that require cutting thick metals or composite materials.

Complex Shape Cutting: Water jet machines excel at cutting complex shapes and intricate patterns with ease. This capability is valuable for industries such as aerospace, automotive, and architectural design, where precise and complex geometries are common.

Reduced Tooling Costs: Water jet cutting eliminates the need for custom tooling or dies, which can be expensive and time-consuming to produce. This flexibility allows for rapid prototyping and efficient production of small to large batches of parts.

Safe for Hazardous Materials: Water jet cutting can safely cut hazardous materials such as asbestos, lead, and certain chemical compounds without releasing harmful substances into the air, ensuring worker safety and compliance with environmental regulations.

Rated Powe | 75KW/100HP | Max. operating pressure | 420Mpa |

Continuous working pressur | 320MPa-380MPa | Max. discharging rate | 7.6L/min |

Orifice diamete | 0.33mm or others | Nozzle diameter | 1.02mm or other |

Tank volume | 180L | Size | 2120mm*1360mm*1510mm |

Weight | 1500kg |

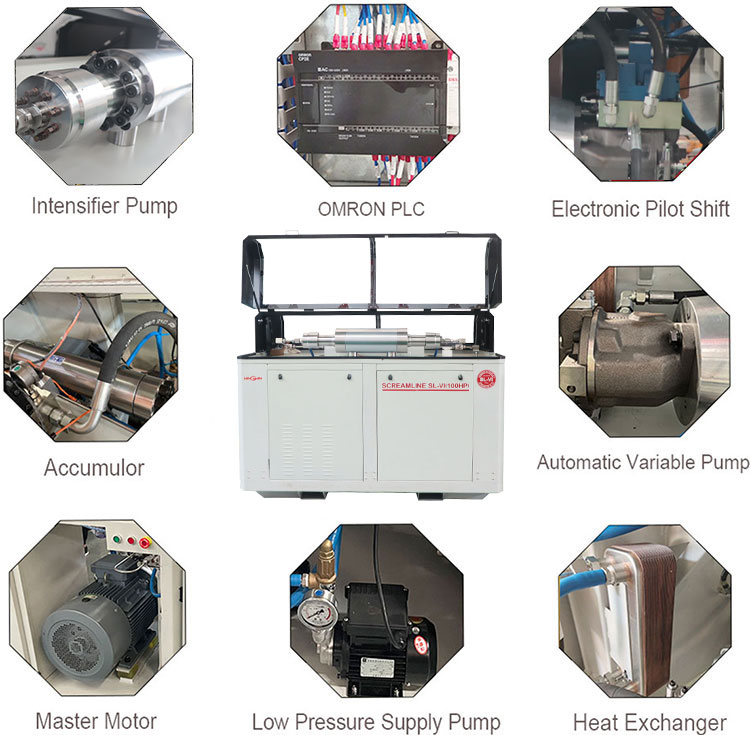

SL-VI 100HP Waterjet pump ————— Features

A. Beautiful appearance and reasonable design

The appearance is more exquisite and beautiful, small and exquisite, the main parts of the intensifier and accumulator are grouped together and installed above the center of the pump, with a transparent acrylic cover, which is convenient to observe the working status at any time.

B. High performance and standard design

Universal structure design, international standard spare parts. High versatility of accessories, customers can purchase the corresponding parts in any waterjet machine market.

C. Newly designed accumulator

Accumulator of new design, integrally forged, without rubber seals, maintenance-free.

D. Double oil filtration system

Double filtration devices are placed at the oil inlet and oil return port to ensure that the oil path is clean, smooth and not blocked, and extend the service life of the waterjet pump.

| WEIHONG WATERJET CNC CONTROL SYSTEM | |

| Brand | WEIHONG® (ENGLISH) |

| Display | Industrial grade display |

| Language | English/Chinese//Others |

| System version | Win10 |

| Format | CAD/G/DXF/ENG/PLT, etc. |

| System Function | AC-5Axis/AB-3Axis |

CNC Control System————— Features

A.Industrial grade screen, special waterjet software, easy to operate.

B.Absolute encoder system, memory function after power failure.

C.Simulation operation, pause and start at any time, continue cutting from any position and point.

D. A more user-friendly and intelligent function has been added, namely the setting and recall function.

Specification for Abrasive Tank | |

| Wall Thickness | 4.5mm (Explosion proof) |

| Air Pressure | 0.2MPa-1MPa |

| Volume | 200kg |

Abrasive Feed Tank ————— Features

A. The automatic abrasive dispensing system continuously supplies abrasive to the abrasive regulator tank on the cutting head next to the large abrasive tank.

B. Without any electrical components, it is maintenance-free, zero defect.

C. Reasonable design enables this large capacity abrasive tank to cut 8-10 hours without interruption.

D. Large diameter flange at the bottom, easy to remove debris.

Specification for cooling:

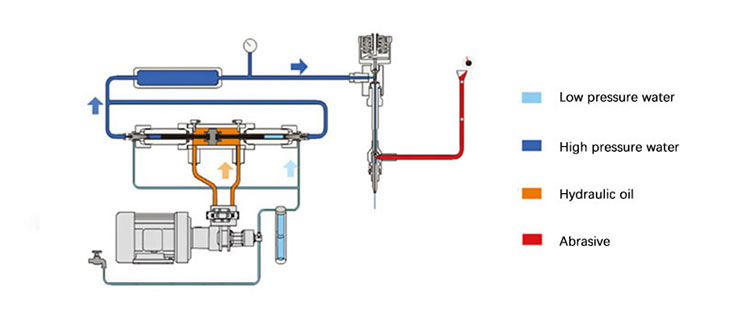

As you know, the pump is driven by hydraulic oil for intensifier work.

Excessive temperature of hydraulic oil will seriously affect the service life of metal parts and sealing parts of the hydraulic part of the intensifier pump.

Refrigerator cooling with super cooling effect, closed internal circulation system, more environmental health, beautiful appearance, reliable performance.

If you are interesting other type of waterjet cutting machine,please contact me when you free.

wwaterjet

wwaterjet