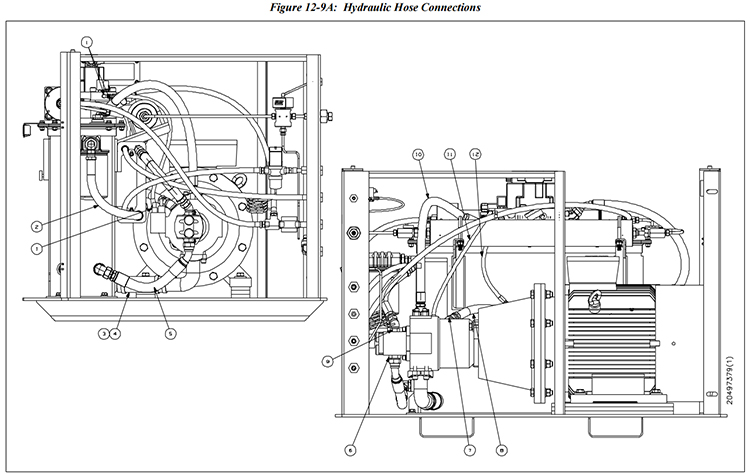

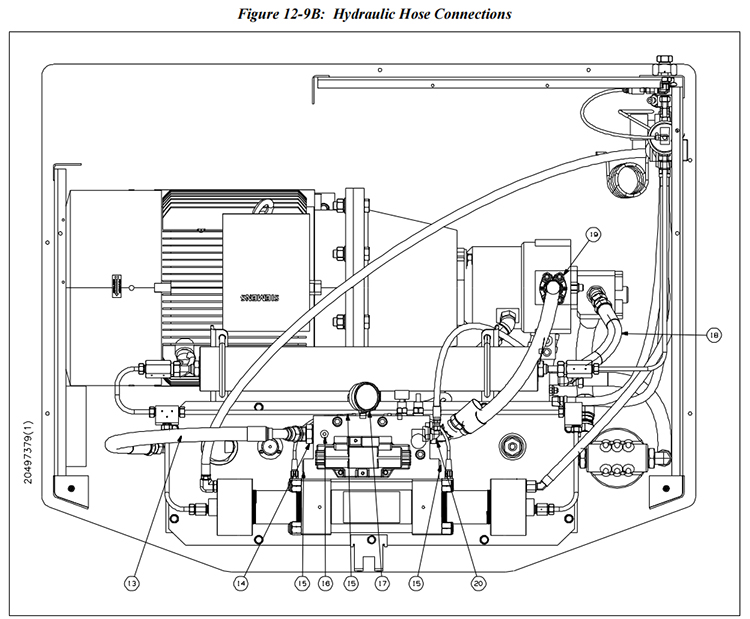

Table 12-9 Hydraulic Hose Connections 20497379 | |||

Item | Part Number | Description | Quantity |

1 | 10142644 | Adapter, JIC/ORB, .25 x .25 | 3 |

2 | 20497437 | Hydraulic Hose Assembly, .75 x 20.50 | 1 |

3 | 10083517 | Hose Clamp | 2 |

4 | 10179018 | Radiator Hose, 2.0 | 8.0" |

5 | 20499618 | Hydraulic Hose Assembly, 1.0 x 16.50 | 1 |

6 | 80086192 | Adapter, JIC/ORB, 1.0 x 1.0 | 1 |

7 | 05052493 | Adapter, JIC/ORB, .75 x .63 | 1 |

8 | 20499652 | Hydraulic Hose Assembly, .75 x 14.0 | 1 |

9 | 05073168 | Adapter, JIC/ORB, .75 x .75 | 1 |

10 | 20497421 | Hydraulic Hose Assembly, 1.0 x .75 x 30.0 | 1 |

11 | 20499576 | Hydraulic Hose Assembly, .25 x 27.0 | 1 |

12 | 20499644 | Hydraulic Hose Assembly, .25 x 15.50 | 1 |

13 | 20497429 | Hydraulic Hose Assembly, .75 x 28.50 | 1 |

14 | 20426972 | Adapter, ORB/JIC, 1.0 x .75 | 1 |

15 | 05122650 | Plug, ORB, .63 | 3 |

16 | 05104559 | Plug, ORB, .38 | 1 |

17 | 05045497 | Pressure Gauge, 0-5000 psi | 1 |

18 | 20499626 | Hydraulic Hose Assembly, .75 x 10.0 | 1 |

19 | 20455137 | Split Flange Kit, 1.0 | 1 |

20 | 10142594 | Adapter, ORB/JIC, 1.0 x .75 | 1 |

Hydraulic hose connections in a waterjet system are essential for safely and efficiently transporting high-pressure hydraulic fluid between various components such as the pump,

intensifier, and actuators. Proper selection, installation, and maintenance of these connections are crucial to ensure the system operates safely and efficiently.

Key Components of Hydraulic Hose Connections

1. Hydraulic Hoses: High-pressure hoses typically made from synthetic rubber, thermoplastic, or PTFE (Polytetrafluoroethylene) reinforced with braided or spiral steel wire.

These hoses are designed to withstand the high pressures and pulsations in a waterjet system.

2. Fittings: Connect the hydraulic hoses to other components like pumps, valves, and actuators. Common types include crimped, reusable, and quick-connect fittings,

usually made from high-strength materials like stainless steel.

3. Adapters: Used to connect hoses with different fitting types or sizes. Adapters can change thread types, sizes, or connect different hydraulic components.

4. Quick-Connect Couplings: Allow for rapid connection and disconnection of hydraulic lines without the need for tools, minimizing downtime and making maintenance easier.

5. O-rings and Seals: Ensure a leak-proof connection between hoses and fittings. These are often made from materials compatible with hydraulic fluid, such as nitrile or Viton.

Best Practices for Hydraulic Hose Connections

Correct Hose Selection: Ensure hoses are rated for the system's maximum operating pressure and temperature. Choose hoses with appropriate inner diameter and

length to minimize pressure drop and avoid kinks.

Proper Fitting Installation: Follow manufacturer guidelines for crimping or assembling fittings. Use the correct tools and techniques to ensure a secure and leak-free connection.Avoid Twisting and Bending: Install hoses without twisting and with minimal bends to prevent stress and potential failure. Use proper routing and support to avoid abrasion and wear.Regular Inspection and Maintenance: Check hoses and connections for signs of wear, leaks, or damage. Replace any compromised components promptly to avoid system failure.Clean Connections: Ensure all connections are clean before assembly to prevent contamination of the hydraulic fluid, which can cause damage to the system.

Troubleshooting Common Issues

Leaks at Connections: Inspect for worn-out O-rings or seals. Ensure fittings are tightened to the correct torque. Replace any damaged components.

Hose Burst or Failure: Verify that the hose rating matches the system's pressure requirements. Check for signs of abrasion, kinks, or excessive bending. Replace the hose if necessary.

Pressure Drop: Ensure hoses are not too long or undersized for the application. Check for internal obstructions or damage that might restrict flow.

Noisy Operation: Could indicate air trapped in the system. Bleed the hydraulic system to remove air. Check for loose fittings that might cause vibrations.

Overheating: Ensure hoses are not in close proximity to heat sources. Verify that the hydraulic fluid is within the recommended temperature range and that the cooling system is functioning properly.

Conclusion

Hydraulic hose connections are critical for the safe and efficient operation of a waterjet system. Proper selection, installation, and maintenance of hoses and fittings

ensure system reliability and longevity. Regular inspections and prompt troubleshooting of issues help maintain optimal performance.

wwaterjet

wwaterjet