Efficient and Stable HPP Components: The Key to Enhancing Equipment Performance

1. Introduction to HPP Components

In modern water jet cutting technology, HPP (High Pressure Pump) components are the core elements that ensure the efficient and stable operation of equipment. HPP components not only affect the cutting precision and speed of water jet equipment, but also impact the lifespan and maintenance costs of the equipment. As crucial parts in the industry, the selection and quality of HPP components directly determine the overall performance of the water jet system. Winwin Waterjet Company, with years of technical accumulation, provides high-quality HPP components, offering customers a more efficient cutting experience.

2. Key Components of HPP Components

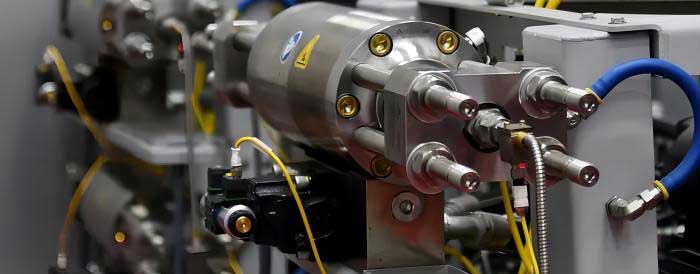

HPP components typically include high-pressure pumps, valves, nozzles, seals, and other important parts. The high-pressure pump, as the core of the HPP system, is responsible for pressurizing the water to a high-pressure state, allowing the water jet machine to maintain stable pressure output during precise cutting. Valves control the flow rate and pressure of the water, while seals ensure that there is no water leakage within the system, ensuring safe operation of the equipment. Nozzles are responsible for the direction of the high-pressure water flow and cutting precision. All of these HPP components work together to ensure the equipment operates efficiently and steadily.

3. Performance Requirements for HPP Components

The quality of each HPP component directly impacts the performance and efficiency of the entire water jet system. The high-pressure pump needs to have strong pressure resistance and be capable of continuously outputting the required high-pressure water flow. The corrosion resistance and high-temperature performance of the valves and seals are also critical, especially in complex working environments. Good sealing can effectively prevent water leakage and corrosion, ensuring safe operation of the system. The wear resistance and precision of the nozzles directly affect cutting results, with high-quality nozzles ensuring smooth cutting edges without losing precision. Overall, the performance requirements for HPP components are high, and durable, stable materials and technology must be selected.

4. Maintenance and Care of HPP Components

To ensure that HPP components run stably over the long term, regular inspections and maintenance are essential. Core components like high-pressure pumps and nozzles may wear out over time, affecting cutting results and system stability. Regularly inspecting the wear of these components and promptly replacing aging or damaged HPP components can effectively extend the equipment's lifespan and maintain cutting efficiency. In particular, seals and valves are prone to corrosion or wear after prolonged high-pressure use, requiring regular replacement.

5. Future Development of HPP Components

With the advancement of technology, the future development of HPP components is moving towards intelligence and modularization. The introduction of smart sensors and automated monitoring systems will make HPP components more precise and efficient. For example, intelligent monitoring systems can track the working status of high-pressure pumps in real-time, detect potential failures in advance, and prevent equipment downtime. In the future, HPP components will further enhance durability, precision, and environmental friendliness to meet increasingly complex and high-demand water cutting requirements.

6. Conclusion

In conclusion, HPP components are indispensable and crucial parts of water jet cutting equipment. Their quality and performance directly determine the cutting results, stability, and lifespan of the equipment. When selecting HPP components, customers should focus on factors such as component quality, performance, and maintenance care. As a professional water jet equipment supplier, Winwin Waterjet Company provides HPP components with excellent performance and long-term stability, helping customers improve production efficiency and reduce operating costs. Whether it is in equipment selection, maintenance, or component replacement, Winwin Waterjet Company offers customers comprehensive technical support.

wwaterjet

wwaterjet