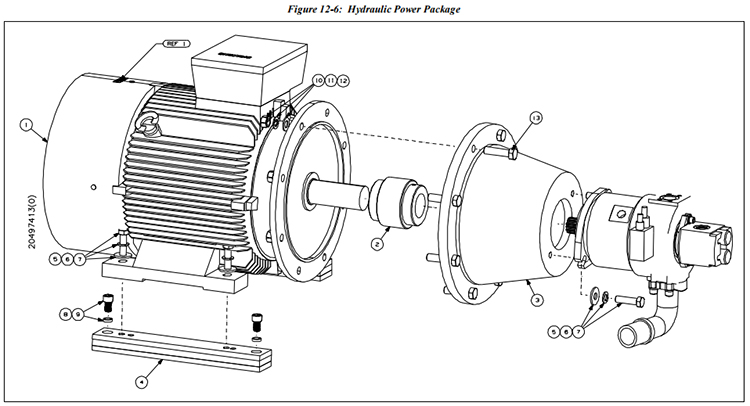

Table 12-6 Hydraulic Power Package 20497413 | |||

Item | Part Number | Description | Quantity |

1 | 20498147 | Electric Motor, 50HP | 1 |

2 | 20498155 | Coupling, Flexible Drive | 1 |

3 | 20498173 | Flange, Motor/Pump | 1 |

4 | 20477284 | Vibration Isolation Mount | 2 |

5 | 49892375 | Hex Head Screw, M16 x 2 x 60MM | 6 |

6 | 49892359 | Lock Washer, M16 | 6 |

7 | 49892342 | Flat Washer, M16 | 6 |

8 | 49833072 | Lock Washer, .63 | 4 |

9 | 20498660 | Socket Head Screw, M16 x 2 x 25MM | 4 |

10 | 20477807 | Hex Nut, M18 | 8 |

11 | 20477803 | Lock Washer, M18 | 8 |

12 | 20477800 | Flat Washer, M18 | 8 |

13 | 20477758 | Hex Head Screw, M18 | 8 |

Ref1 | 10091510 | Arrow Decal -- | |

The hydraulic power package in a waterjet system is responsible for generating and controlling the high-pressure hydraulic fluid that drives the intensifier pump,

which in turn pressurizes the water for cutting operations. This package is crucial for ensuring the consistent and reliable operation of the waterjet system.

Key Components of a Hydraulic Power Package

1. Hydraulic Pump: Converts mechanical energy into hydraulic energy, typically driven by an electric motor. It provides the necessary pressure and flow to the intensifier.

2. Electric Motor: Powers the hydraulic pump. The motor's size and power depend on the requirements of the waterjet system.

3. Reservoir: Stores the hydraulic fluid and helps in cooling and filtering it. The reservoir must be appropriately sized to accommodate the system's needs.

4. Filters: Remove contaminants from the hydraulic fluid to prevent damage to the pump and other components.

5. Heat Exchanger/Cooler: Keeps the hydraulic fluid at an optimal operating temperature, preventing overheating and maintaining efficiency.

6. Pressure Relief Valves: Ensure the system does not exceed safe operating pressures, protecting components from damage.

7. Control Valves: Regulate the flow and pressure of the hydraulic fluid to control the intensifier pump's operation.

8. Accumulators: Store hydraulic energy and help in maintaining constant pressure and compensating for pressure fluctuations.

9. Pressure Gauges and Sensors: Monitor the hydraulic pressure within the system to ensure it is within the desired range.

10. Piping and Hoses: Transport hydraulic fluid between the pump, intensifier, and other components. These must be rated for high-pressure operation.

Maintenance Tips

Regular Inspection: Check for leaks, wear, and damage in hoses, fittings, and other components.

Fluid Maintenance: Regularly check and replace hydraulic fluid according to the manufacturer's recommendations. Ensure the fluid is clean and at the correct level.

Filter Replacement: Replace filters periodically to maintain fluid cleanliness and protect the system from contaminants.

Cooling System Maintenance: Ensure the heat exchanger or cooler is functioning correctly and not obstructed. Check coolant levels if applicable.

Check Pressure Settings: Verify that pressure relief valves and control valves are set to the correct pressures to prevent system damage.

Troubleshooting Common Issues

Overheating: Check the heat exchanger/cooler, ensure proper fluid levels, and verify that the system is not operating beyond its capacity.

Low Pressure: Inspect for leaks, check fluid levels, and ensure the pump is functioning correctly. Replace worn components as needed.

Fluid Contamination: Regularly replace filters and ensure the reservoir is sealed correctly. Use high-quality hydraulic fluid.

Noisy Operation: Could indicate air in the system, low fluid levels, or worn components. Bleed the system to remove air and check for proper fluid levels and component condition.

Conclusion

The hydraulic power package is vital for the efficient and reliable operation of a waterjet system. Regular maintenance, prompt troubleshooting of issues,

and adherence to manufacturer guidelines will ensure the longevity and performance of the system.

wwaterjet

wwaterjet