Construction thick metal cutting solutions 100000PSI

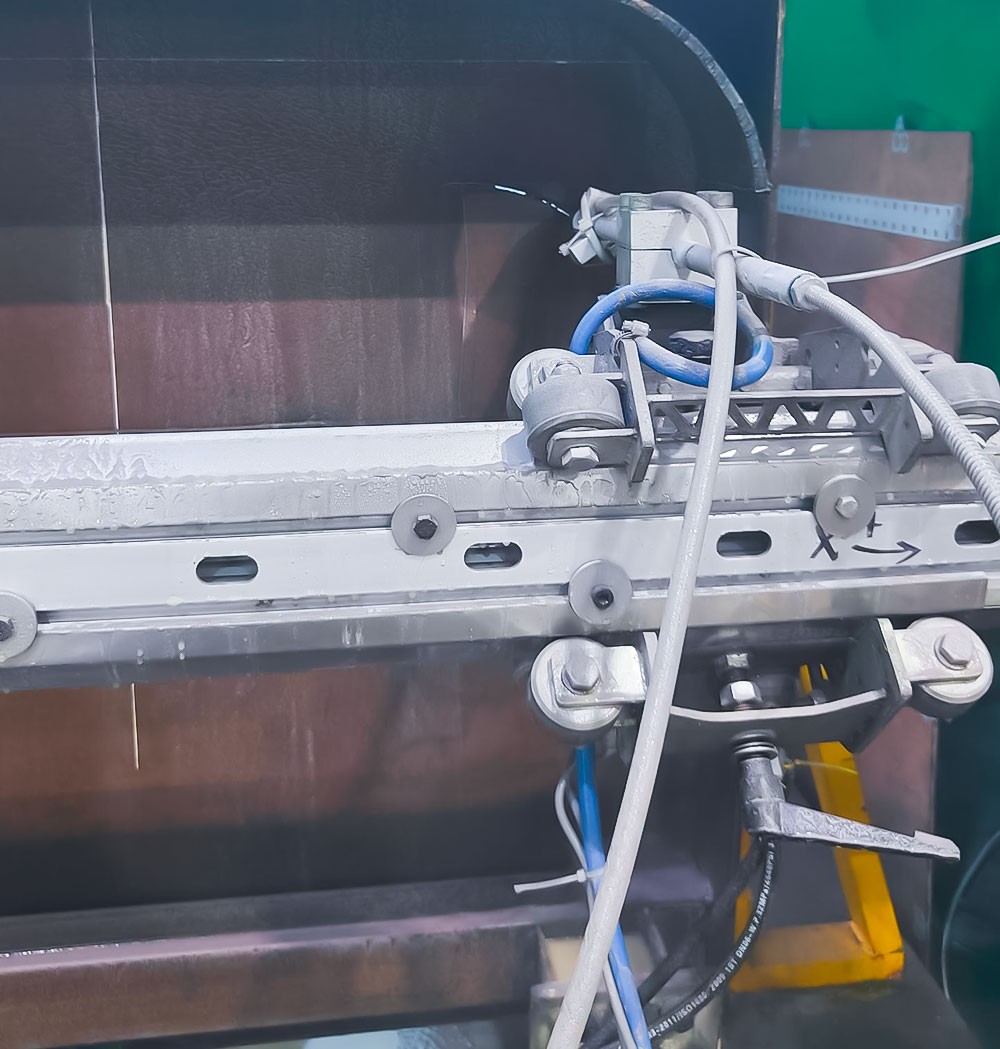

Portable Waterjet cutting

When it comes to thick metal cutting solutions using portable waterjet cutting technology at 100,000 PSI,

it's crucial to ensure that the equipment is robust, efficient, and safe for use. Portable waterjet cutting

machines offer a versatile and effective method for cutting a wide range of materials, including thick

metals. Operating at high pressures like 100,000 PSI allows for precise and clean cuts even through

challenging materials.

Industries that deal with ultra-thick metal applications typically require specialized equipment and processes

to handle the challenges posed by cutting or manipulating extremely thick metal materials. Some industries

where ultra-thick metal applications are common include:

Shipbuilding and Maritime Industry:

Shipbuilding and repair often involve working with ultra-thick metal plates for constructing hulls, bulkheads,

and other structural components.

Offshore Oil and Gas Industry:

Platforms, pipelines, and other structures in the offshore oil and gas industry require the use of ultra-thick

metal materials for their construction and maintenance.

Heavy Machinery and Equipment Manufacturing:

Industries involved in manufacturing heavy machinery, such as construction equipment, mining machinery,

and industrial machinery, often work with ultra-thick metal components.

Aerospace and Defense Industry:

Aircraft and defense equipment manufacturing frequently involve the use of ultra-thick metal materials for

various structural components and armor plating.

Infrastructure and Construction:

Infrastructure projects, such as bridges, dams, and high-rise buildings, sometimes involve the use of ultra-thick

metal materials for structural purposes.

Mining and Resources Industry:

The mining industry utilizes ultra-thick metal materials for equipment used in mining operations, such as drills,

excavators, and haul trucks.

Energy Industry:

Power generation facilities, including nuclear power plants and hydroelectric dams, may require ultra-thick metal

components for their construction and maintenance.

Rail and Transportation Industry:

The rail and transportation industry may use ultra-thick metal materials for the construction of railway tracks,

bridges, and rolling stock such as locomotives and railcars.

These industries often rely on advanced cutting, welding, forming, and machining technologies to work with

ultra-thick metal materials effectively and efficiently. Waterjet cutting, laser cutting, plasma cutting, and other

specialized techniques are commonly employed in these sectors to process thick metal components accurately.

What are the difficulties in water jet cutting of ultra-thick metals?

Water jet cutting is a versatile and effective method for cutting a wide range of materials, including ultra-thick

metals. However, when it comes to cutting ultra-thick metals using water jet technology, several challenges and

difficulties may arise

keep waterjet cutting pressure at 520-550Mpa

Design of cutting mechanism

Win-Win Waterjet Portable waterjet cutting allows for intricate designs and shapes to be cut accurately,

offering customization options for clients in various industries.allow for on-site cutting, eliminating the

need to transport heavy materials to a cutting facility. This convenience saves time and money for customers.

If you are searching portable waterjet cutting solution, feel free contact win-win waterjet

wwaterjet

wwaterjet