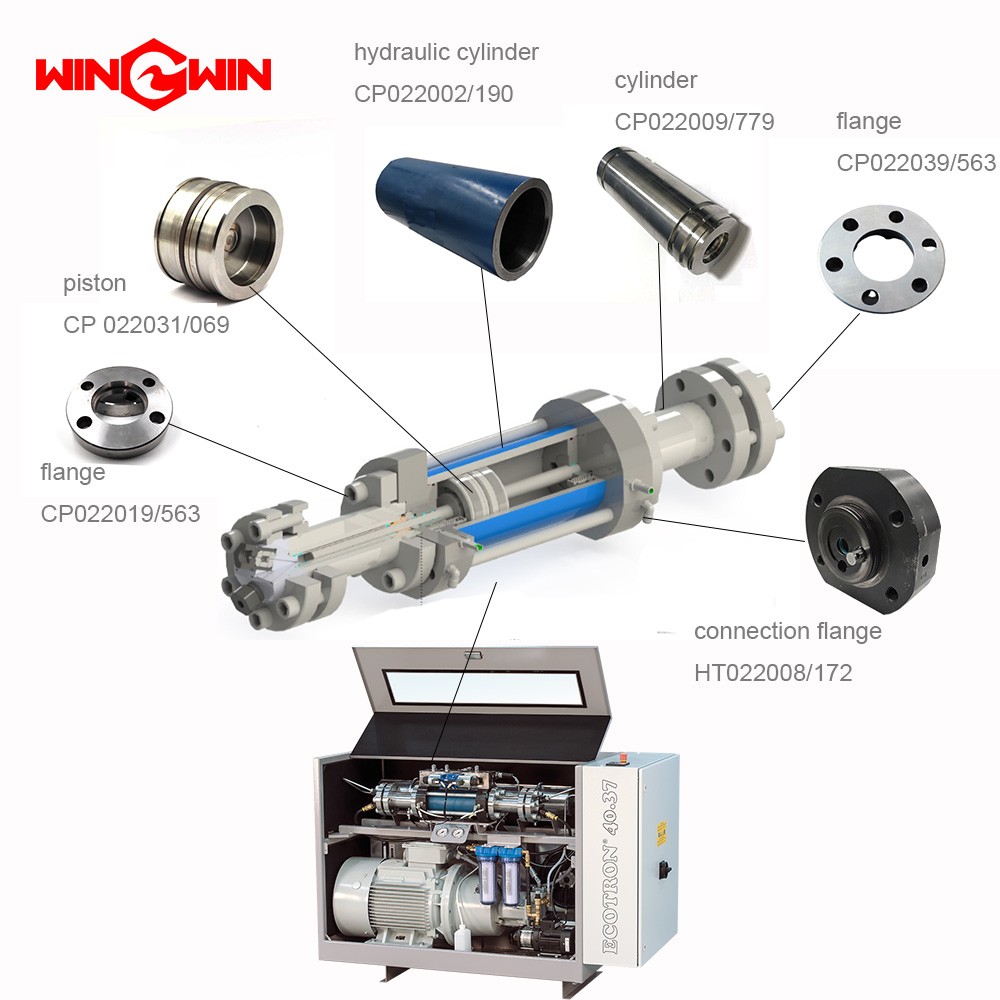

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

CP022042/593 lense for BFT waterjet

There are several factors that can contribute to hydraulic cylinder damage in a waterjet cutting system. Here are some common causes of hydraulic cylinder damage:

Over-pressurization: Exceeding the recommended operating pressure of the waterjet cutting system can cause damage to the hydraulic cylinder. This can result in leaks, reduced performance, and even catastrophic failure of the system.

Overuse: Overuse of the waterjet cutting system, particularly at high pressures, can cause wear and tear on the hydraulic cylinder over time. This can lead to leaks, reduced performance, and other issues with the system.

Contaminated fluid: Contaminated hydraulic fluid, such as fluid with high levels of moisture or other impurities, can cause damage to the hydraulic cylinder over time. Moisture can cause rust and corrosion, which can result in leaks and reduced performance.

Improper installation: Incorrect installation of the hydraulic cylinder can cause damage to the cylinder and other components of the waterjet cutting system. It is important to follow the manufacturer's recommendations for installation and maintenance to ensure proper operation of the system.

Age and wear: Hydraulic cylinders, like all components of the waterjet cutting system, can wear out over time. Regular replacement of the hydraulic cylinder is important to ensure that the system is operating at peak performance and to prevent damage to other components of the system.

It is important to address any issues with the hydraulic cylinder as soon as they are identified to prevent further damage to thesystem and ensure proper cutting performance. Regular maintenance and inspection of the hydraulic cylinder are an important part of preventive maintenance for the waterjet cutting system and can help prevent issues with the cylinder and other components of the system. It is important to follow the manufacturer's recommendations for maintenance and perform regular inspections to identify any potential issues before they cause damage to the system.

Working with an experienced and knowledgeable technician can help identify the cause of the hydraulic cylinder issues and recommend the appropriate course of action to address them. Regular maintenance and proactive measures can help prevent damage to the hydraulic cylinder and ensure that your waterjet cutting system is operating at peak performance.

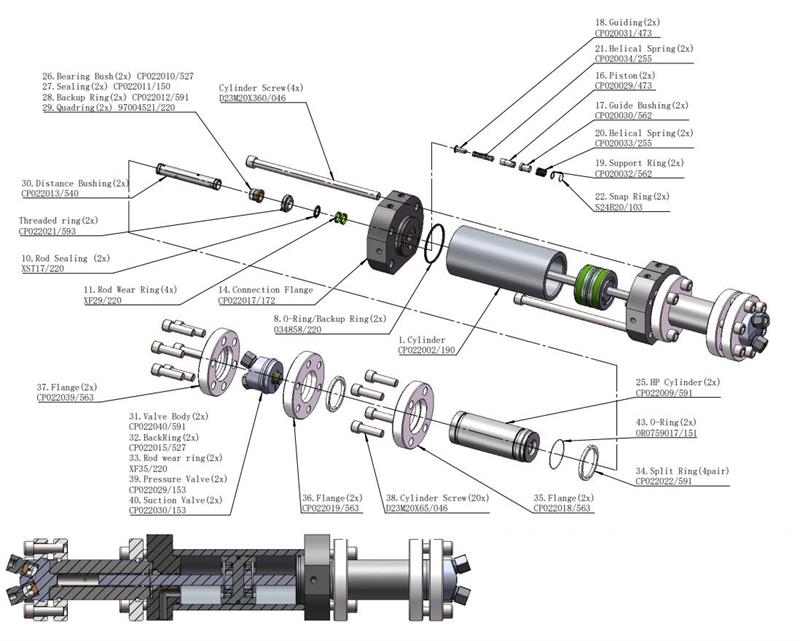

| CP022002/190 | Cylinder |

| 1200402 | piston complete |

| XK121/220 | Piston sealing |

| XF56/220 | Wear ring |

| CP022066/220 | Plunger complete |

| CP022057/075 | Clamp ring |

| HT022044/103 | Retaining ring |

| 034858/220 | O-ring backring 97 |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XF29/220 | Rod wear ring 22x27x5,6 mm |

| D23M20360/046 | Cylinder head screw |

| CP022017/172 | connection flange |

| CP022016/172 | connection flange |

| CP022021/593 | Thread ring |

| HT022004/473 | Piston |

| CP020030/562 | Bushing |

| CP020031/473 | Guiding |

| CP020032/562 | Supporting ring |

| CP020033/255 | helical spring |

| CP020034/255 | helical spring |

| CP020034/255 | Helical spring |

| S24B20/103 | Snap ring |

| xn5/220 | initiator |

| XST9/220 | PLUG |

| CP022009/779 | High pressure cylinder |

| CP022010/527 | Bearing bush |

| CP022011/150 | Sealing |

| CP022012/780 | Back ring |

| 9704521/220 | Quadring |

| CP022013/014 | Distance bushing |

| CP022040/591 | Valve body |

| CP022015/527 | Back ring |

| XF35/220 | Rod wear ring |

| CP022022/591 | SPLIT RING |

| CP022018/563 | Flange |

| CP022019/563 | Flange |

| CP022039/563 | Flange |

| D23M20*65/046 | Cylinder head screw |

| CP022047/844 | Pressure valve |

| CP022019/844 | suction valve |

| MA160818/220 | swivel male elbow |

| OR0759017/151 | o-ring75.92*1.78 |

wwaterjet

wwaterjet