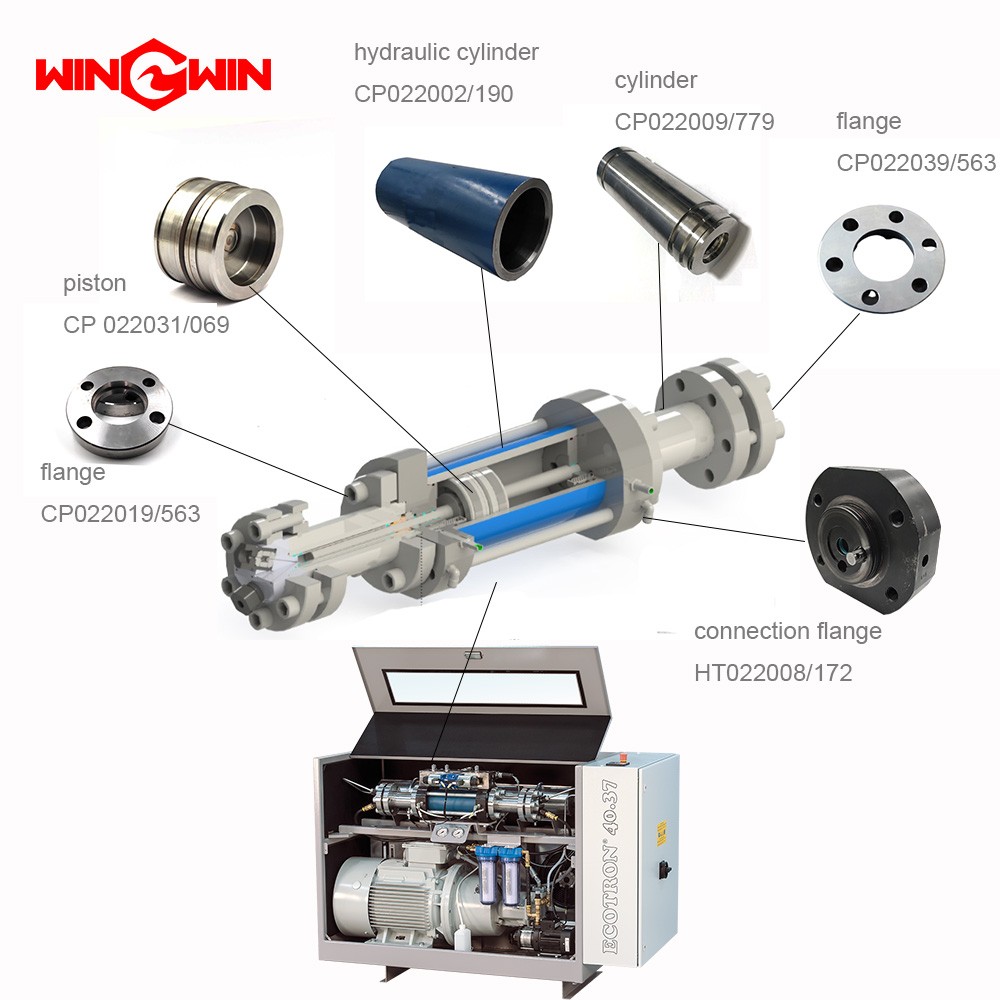

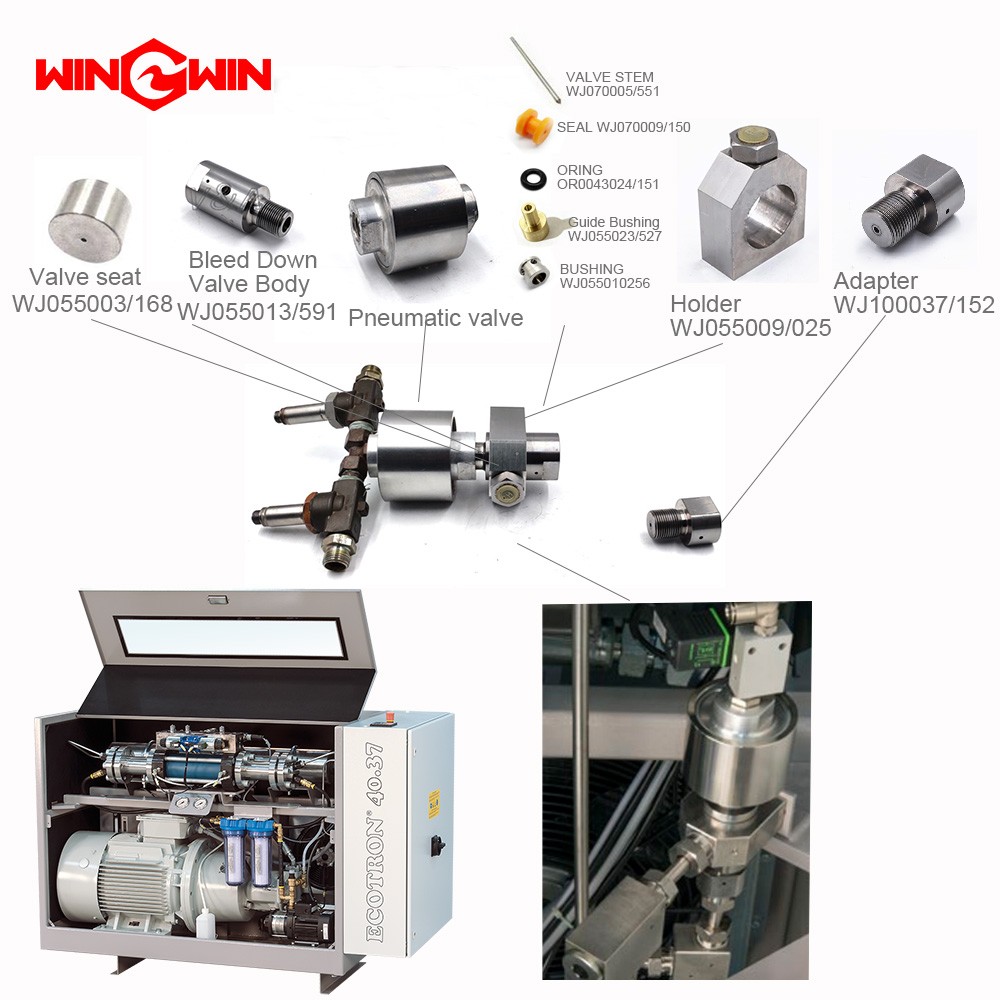

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

CP022009/591 waterjet cylinder for BFT waterjet

The frequency of inspection for the intensifier cylinder can vary depending on several factors, including the age of the pump, the amount of use it receives, and the operating conditions. However, as a general guideline, it is recommended to have the intensifier cylinder inspected at least once per year or after every 2,000 to 3,000 hours of operation, whichever comes first.

Regular inspection of the intensifier cylinder is important to ensure that it is functioning properly and to detect any potential issues before they cause damage to the pump or other components of the waterjet cutting system. During the inspection, the technician will typically check for signs of wear or damage, such as cracks, corrosion, or leaks. They may also inspect the seals, valves, and other components of the cylinder to ensure they are functioning correctly.

In addition to regular inspections, it is important to perform regular maintenance on the waterjet cutting system to prevent issues with the intensifier cylinder and other components. This can include changing filters, inspecting hoses and fittings, and performing other routine maintenance tasks as recommended by the manufacturer.

If you notice any signs of problems with the intensifier cylinder, such as reduced cutting pressure, increased noise, or leaks, it is important to have the system inspected and repaired as soon as possible to prevent further damage and ensure proper cutting performance. Working with an experienced and knowledgeable technician can help ensure that your waterjet cutting system is properly maintained and operating at peak performance.

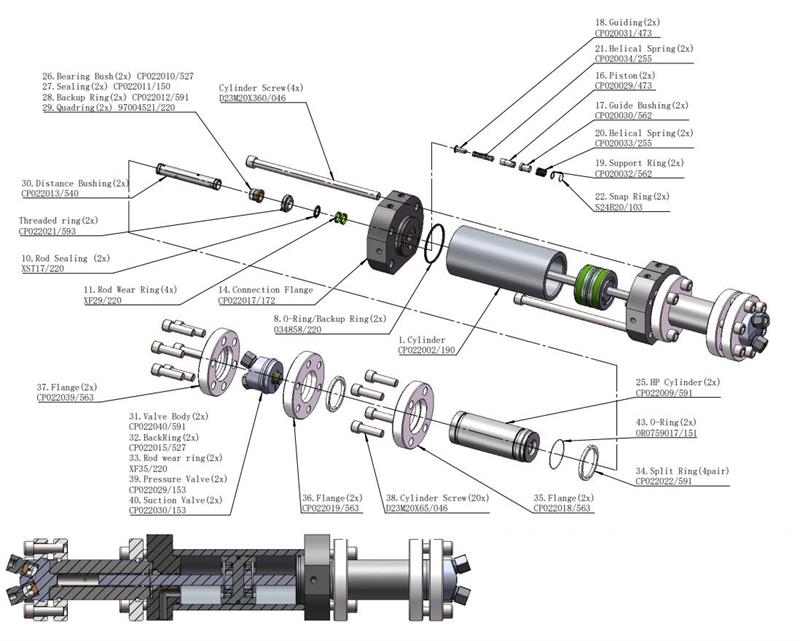

| CP022002/190 | Cylinder |

| 1200402 | piston complete |

| XK121/220 | Piston sealing |

| XF56/220 | Wear ring |

| CP022066/220 | Plunger complete |

| CP022057/075 | Clamp ring |

| HT022044/103 | Retaining ring |

| 034858/220 | O-ring backring 97 |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XST17/220 | Rod sealing 22,0 x 32,7 x 4,2 mm |

| XF29/220 | Rod wear ring 22x27x5,6 mm |

| D23M20360/046 | Cylinder head screw |

| CP022017/172 | connection flange |

| CP022016/172 | connection flange |

| CP022021/593 | Thread ring |

| HT022004/473 | Piston |

| CP020030/562 | Bushing |

| CP020031/473 | Guiding |

| CP020032/562 | Supporting ring |

| CP020033/255 | helical spring |

| CP020034/255 | helical spring |

| CP020034/255 | Helical spring |

| S24B20/103 | Snap ring |

| xn5/220 | initiator |

| XST9/220 | PLUG |

| CP022009/779 | High pressure cylinder |

| CP022010/527 | Bearing bush |

| CP022011/150 | Sealing |

| CP022012/780 | Back ring |

| 9704521/220 | Quadring |

| CP022013/014 | Distance bushing |

| CP022040/591 | Valve body |

| CP022015/527 | Back ring |

| XF35/220 | Rod wear ring |

| CP022022/591 | SPLIT RING |

| CP022018/563 | Flange |

| CP022019/563 | Flange |

| CP022039/563 | Flange |

| D23M20*65/046 | Cylinder head screw |

| CP022047/844 | Pressure valve |

| CP022019/844 | suction valve |

| MA160818/220 | swivel male elbow |

| OR0759017/151 | o-ring75.92*1.78 |

wwaterjet

wwaterjet