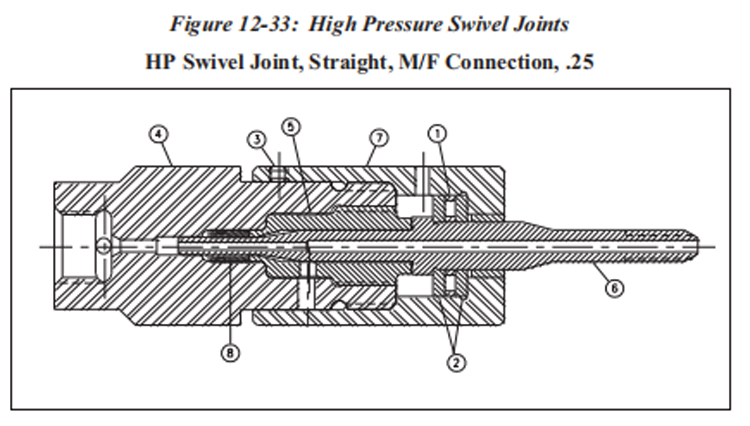

Table 12-43 High Pressure Swivel Joints | |||

Item | Part Number | Description | Quantity |

CJ211388 | HP Swivel Joint, Straight, .25, M/F | ||

1 | 10084713 | Thrust Needle Bearing | 1 |

2 | 10094647 | Thrust Washer | 2 |

3 | 10103505 | Setscrew, 6-32 x 1/8 | 1 |

4 | CJ311388 | Swivel Body | 1 |

1 | CJ401288 | Swivel Bushing | 1 |

6 | CJ501288 | Spindle, .25 | 1 |

7 | BJ701288 | Cap Assembly | 1 |

8 | BJ201388 | Seal Assembly | 1 |

BJ701288 | Cap Assembly | ||

1 | CJ801288 | Cap, .25/.38, M/F | 1 |

2 | 10144442 | Swivel Bushing | 1 |

High-pressure swivel joints in a waterjet system play a critical role in maintaining continuous fluid flow while allowing rotational movement. Here are some key aspects of waterjet high-pressure swivel joints:

1. Functionality: Swivel joints enable the connection between high-pressure hoses or pipes, allowing fluid (water or water mixed with abrasives) to flow into the cutting head while accommodating rotational movement without disrupting the flow.

2. High-Pressure Operation: These joints are designed to withstand extremely high pressures commonly found in waterjet systems, typically ranging from 30,000 to 90,000 psi or higher, ensuring leak-free operation under high-pressure conditions.

3. Rotational Capability: Swivel joints offer rotational flexibility, allowing the cutting head or nozzle assembly to rotate or pivot as needed while maintaining a consistent flow of water or abrasive mixture.

4. Materials and Construction: They are constructed using materials capable of withstanding high pressures and abrasive wear. Stainless steel or specialized alloys are commonly used to ensure durability and resistance to corrosion.

5. Seals and Bearings: Swivel joints incorporate high-quality seals and bearings to prevent leaks and reduce friction during rotation, ensuring smooth operation and longevity.

6. Precision and Reliability: The design and construction of these components are crucial to maintaining precision and reliability in the waterjet system's fluid delivery, minimizing downtime and ensuring continuous cutting operations.

Swivel joints are essential components in waterjet systems, enabling the delivery of high-pressure fluids while allowing for the necessary movement and flexibility required during the cutting process. Their durability and ability to maintain leak-free operation under extreme pressures contribute significantly to the overall efficiency of waterjet cutting systems.

wwaterjet

wwaterjet