How much do you know about abrasive waterjet cutting machine?

1. What is the abrasive waterjet cutting machine?

An abrasive waterjet cutting machine is a tool used for precision cutting of various materials using a high-pressure stream of water mixed with abrasive particles. The basic principle involves pressurizing water, typically to extremely high levels, and then forcing it through a small nozzle at high velocity. This results in a powerful stream that can cut through materials ranging from soft substances like foam to hard materials like metals and composites.

The addition of abrasive particles, usually garnet or aluminum oxide, to the water stream enhances the cutting capability, allowing the waterjet to cut through tougher materials. The abrasive particles added to the water serve to erode the material being cut, essentially sanding it away as the waterjet moves across the surface.

Abrasive waterjet cutting is known for its versatility, as it can cut through materials of varying thicknesses and densities with high precision and minimal heat-affected zones. This makes it suitable for a wide range of applications across industries such as aerospace, automotive, manufacturing, and construction. It's often used for cutting materials like metals, stone, glass, ceramics, plastics, and composites.

Overall, abrasive waterjet cutting machines offer a flexible and efficient solution for precision cutting tasks, particularly when dealing with complex shapes or delicate materials.

2.What are the styles of Abrasive waterjet cutting machine?

uGantry abrasive waterjet machine

A gantry abrasive waterjet machine is a type of abrasive waterjet cutting system characterized by its gantry structure. The gantry typically refers to the overhead framework that supports and guides the movement of the cutting head and the material being cut.

In a gantry-style abrasive waterjet machine, the cutting head is mounted on a crossbeam that moves along the gantry structure in a horizontal direction, while the material to be cut is placed on a stationary or movable worktable underneath. This configuration allows for precise and controlled movement of the cutting head across the material, enabling accurate cutting of complex shapes and designs.

Gantry abrasive waterjet machines are often used for cutting large workpieces or materials that require high precision and stability during the cutting process. They are commonly employed in industries such as aerospace, automotive, architecture, and manufacturing for tasks such as cutting metal sheets, composite materials, stone, glass, and more.

uCantilever abrasive waterjet machine

A cantilever abrasive waterjet machine is another type of abrasive waterjet cutting system, distinguished by its cantilevered design. In this configuration, the cutting head is mounted on a beam that extends horizontally from one side of the machine, while the material to be cut is typically placed on a stationary or movable worktable underneath.

The cantilever design allows for easy access to the work area from three sides, as one side of the machine is left open. This can be advantageous for loading and unloading materials, as well as for facilitating maintenance and cleaning tasks.

Cantilever abrasive waterjet machines are often used in applications where space is limited or where access to the work area from multiple sides is necessary. They are suitable for cutting a wide range of materials, including metals, composites, plastics, glass, and stone.

uGantry/Cantilever flip platform abrasive waterjet machine

A Gantry/Cantilever flip platform abrasive waterjet machine combines features of both gantry and cantilever designs with the addition of a flip platform. This type of machine offers versatility in terms of cutting configurations and material handling.

Flip Platform: The flip platform feature allows the worktable or cutting bed to be flipped or rotated, providing access to both sides of the material being cut. This allows for double-sided cutting without the need for manual repositioning of the material.

Combining these features, the gantry/cantilever flip platform abrasive waterjet machine offers flexibility and efficiency in cutting various materials from multiple angles and sides. It can be particularly useful for applications requiring intricate cuts or when working with materials that need to be cut from both sides.

This type of machine is commonly used in industries such as aerospace, automotive, and manufacturing where complex cutting requirements are common, and efficient material handling is essential for productivity.

uPortable abrasive waterjet machine

A portable abrasive waterjet machine is a compact and mobile version of traditional abrasive waterjet cutting systems. Unlike larger stationary machines, portable waterjet systems are designed to be easily transported to different job sites or locations where cutting needs arise. These machines offer flexibility and convenience, especially for applications where bringing the workpiece to a fixed cutting location is impractical or not feasible.

3.What are the sizes of commonly used abrasive waterjet cutting platforms?

Gantry integrated structure:2015、2515、3015、3018、4018.

Cantilever structure:3020、4020

Other sizes can be customized by communicating with WINWIN.

4.What are the main cutting heads of Abrasive waterjet platform?

Three-axis cutting head:

A three-axis waterjet cutting head is a component of an abrasive waterjet cutting system that allows for precise control over the orientation of the cutting stream in three dimensions: X, Y, and Z axes. This type of cutting head enables the waterjet to cut materials at various angles and contours, offering greater flexibility and capability in cutting complex shapes and designs.

Here's how the three-axis cutting head typically operates:

4.1 X and Y Axes: The X and Y axes control the horizontal movement of the cutting head across the workpiece. These movements are typically controlled by the machine's computer numerical control (CNC) system, which guides the cutting head along the desired cutting path with high precision.

4.2 Z Axis: The Z axis controls the vertical movement of the cutting head, allowing it to adjust the height above the workpiece. This movement is crucial for maintaining the optimal cutting distance between the nozzle and the material surface, which ensures efficient cutting and minimizes the risk of nozzle damage.

4.3 Angle Adjustment: In addition to the X, Y, and Z axes, the three-axis cutting head may also have the capability to adjust the angle of the cutting stream relative to the material surface. This allows for cutting at various angles and bevels, expanding the range of possible cuts and enabling the creation of complex shapes with beveled edges.

The three-axis cutting head is essential for achieving precision and versatility in abrasive waterjet cutting applications. It allows for intricate cuts, sharp corners, and smooth contours, making it suitable for a wide range of industries and materials, including metals, plastics, ceramics, composites, and more.

Five-axis cutting head:

A five-axis waterjet cutting head is an advanced component of an abrasive waterjet cutting system that adds two additional axes of motion to the traditional three-axis system. This allows for even greater flexibility and precision in cutting complex shapes and contours, including three-dimensional surfaces. The five-axis cutting head enables the waterjet to adjust its orientation in multiple directions, providing enhanced cutting capabilities for a wide range of applications.

Here's how the five-axis waterjet cutting head typically operates:

4.4 X, Y, and Z Axes: Similar to the three-axis cutting head, the X, Y, and Z axes control the horizontal, vertical, and depth movements of the cutting head, respectively. These movements enable the cutting head to move along the workpiece in three dimensions, following the programmed cutting path with high precision.

4.5 A and B Axes (Rotational Axes): The A and B axes are additional rotational axes that allow the cutting head to tilt or swivel in two perpendicular directions. This rotation capability enables the cutting head to adjust its angle relative to the material surface, allowing for bevel cutting, chamfering, tapering, and complex 3D cutting.

By combining both linear and rotational movements, the five-axis waterjet cutting head can approach the workpiece from various angles and orientations, resulting in precise and intricate cuts that would be challenging or impossible to achieve with fewer axes of motion. This versatility makes the five-axis cutting head well-suited for cutting complex shapes, contours, and multi-sided parts, as well as for creating smooth transitions between different surfaces.

Five-axis waterjet cutting systems are used in a variety of industries, including aerospace, automotive, marine, architecture, and manufacturing, where high precision and intricate cutting requirements are common. They offer advanced capabilities for cutting a wide range of materials, including metals, composites, ceramics, glass, stone, and plastics, with exceptional accuracy and efficiency.

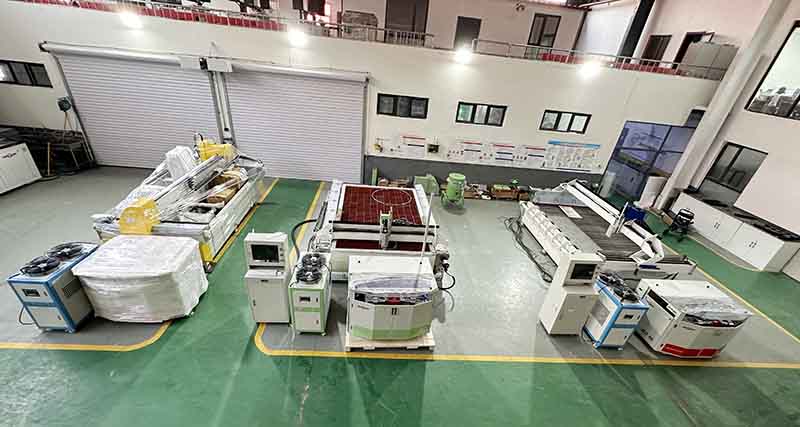

5.Main configuration of waterjet platform:

Waterjet Pump

Cooling

cutting platform

Cutting Head

Control cabinet

Sand remover (optional)

Demineralized water (optional)

If you need more detailed information, please contact WINWIN sales, we will provide you with professional technical support, follow up on your needs and provide reasonable solutions and quotations!

wwaterjet

wwaterjet