Table 12-40 Standard Sapphire Orifice | |

Part Number | Description |

A2260001 | 0.001" (0.025 mm) |

A2260002 | 0.002" (0.051 mm) |

A2260003 | 0.003" (0.076 mm) |

A2260004 | 0.004" (0.102 mm) |

A2260005 | 0.005" (0.127 mm) |

A2260006 | 0.006" (0.152 mm) |

A2260007 | 0.007" (0.178 mm) |

A2260008 | 0.008" (0.203 mm) |

A2260009 | 0.009" (0.229 mm) |

A2260010 | 0.010" (0.254 mm) |

A2260011 | 0.011" (0.279 mm) |

A2260012 | 0.012" (0.305 mm) |

A2260013 | 0.013" (0.330 mm) |

A2260014 | 0.014" (0.356 mm) |

A2260015 | 0.015" (0.381 mm) |

A2260016 | 0.016" (0.406 mm) |

A2260018 | 0.018" (0.457 mm) |

A2260019 | 0.019" (0.483 mm) |

A2260020 | 0.020" (0.508 mm) |

A2260021 | 0.021" (0.533 mm) |

A2260022 | 0.022" (0.559 mm) |

A2260024 | 0.024" (0.610 mm) |

A2260028 | 0.028" (0.711 mm) |

A2260032 | 0.032" (0.813 mm) |

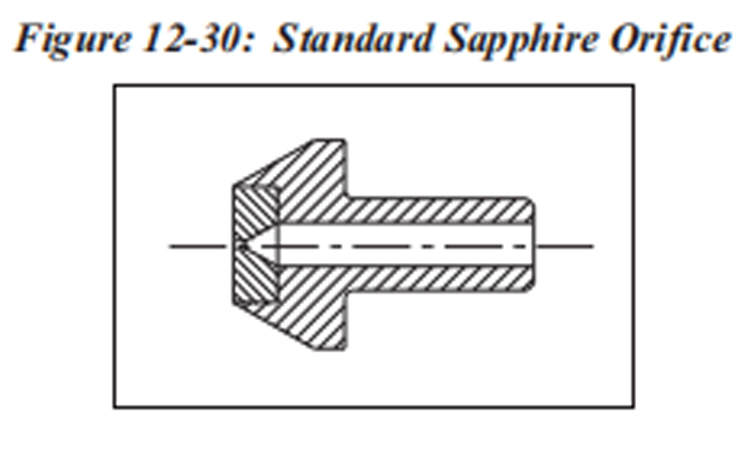

A standard sapphire orifice in waterjet cutting refers to a component that serves a vital role in controlling the flow and direction of the high-pressure water jet during the cutting process. Key features of a standard sapphire orifice include:

1. Material Composition:Standard sapphire orifice Made from synthetic sapphire, known for its durability, hardness, and resistance to wear caused by high-pressure water and abrasive materials.

2. Precision Opening: The orifice has a precisely engineered small opening that shapes and controls the waterjet stream's flow, ensuring accuracy and control during cutting operations.

3. Consistent Cutting Performance: Sapphire orifices provide reliable and consistent cutting performance due to their hardness and resistance to erosion, maintaining a stable stream over prolonged use.

4. Compatibility: Designed to fit specific waterjet cutting systems and nozzle configurations, ensuring proper installation and functionality.

5. Abrasion Resistance: Sapphire orifices are capable of withstanding the abrasive wear caused by the high-velocity water and abrasive particles, extending their operational lifespan.

6. Critical Component: The orifice's design and quality significantly influence the precision, speed, and efficiency of the cutting process, making it a critical component in waterjet systems.

These orifices are essential in controlling and shaping the high-pressure water stream, ensuring precise and consistent cutting performance in various materials across different industries.

wwaterjet

wwaterjet