Table 12-41 Standard Diamond Orifice | |

Part Number | Description |

49888852 | 0.003" (0.076 mm) |

49888860 | 0.004" (0.102 mm) |

49888878 | 0.005" (0.127 mm) |

49888886 | 0.006" (0.152 mm) |

49888894 | 0.007" (0.178 mm) |

49888902 | 0.008" (0.203 mm) |

49888910 | 0.009" (0.229 mm) |

49888928 | 0.010" (0.254 mm) |

49888936 | 0.012" (0.305 mm) |

49836786 | 0.013" (0.330 mm) |

49888944 | 0.014" (0.356 mm) |

49888951 | 0.015" (0.381 mm) |

49888969 | 0.016" (0.406 mm) |

49888977 | 0.018" (0.457 mm) |

20436198 | 0.019" (0.483 mm) |

49888985 | 0.020" (0.508 mm) |

49888993 | 0.022" (0.559 mm) |

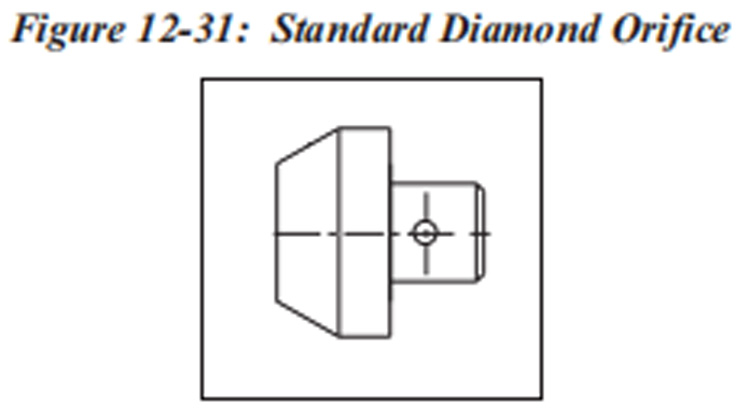

A standard diamond orifice in waterjet cutting is a key component that plays a critical role in controlling and shaping the high-pressure water jet during the cutting process. Here are some key aspects of a standard diamond orifice:

1. Material Composition: Diamond orifices are made from synthetic diamonds, known for their extreme hardness and resistance to wear caused by high-pressure water and abrasive materials.

2. Precision Opening: The orifice contains a precisely engineered small opening that shapes and controls the waterjet stream's flow, ensuring accuracy and control during cutting operations.

3. Durability and Abrasion Resistance: Diamond orifices are highly durable and offer exceptional resistance to erosion, making them suitable for cutting hard and abrasive materials without significant wear.

4. Consistency in Cutting Performance: Due to their exceptional hardness, diamond orifices provide consistent and reliable cutting performance, maintaining a stable stream for extended periods.

5. Compatibility: These orifices are designed to fit specific waterjet cutting systems and nozzle configurations, ensuring proper installation and functionality.

6. Critical Component: The design and quality of the orifice significantly influence the precision, speed, and efficiency of the cutting process, making it a critical component in waterjet systems.

Diamond orifices are often preferred for applications involving cutting hard materials, such as ceramics, glass, stone, and metals, where high wear resistance and precise cutting performance are required.

wwaterjet

wwaterjet