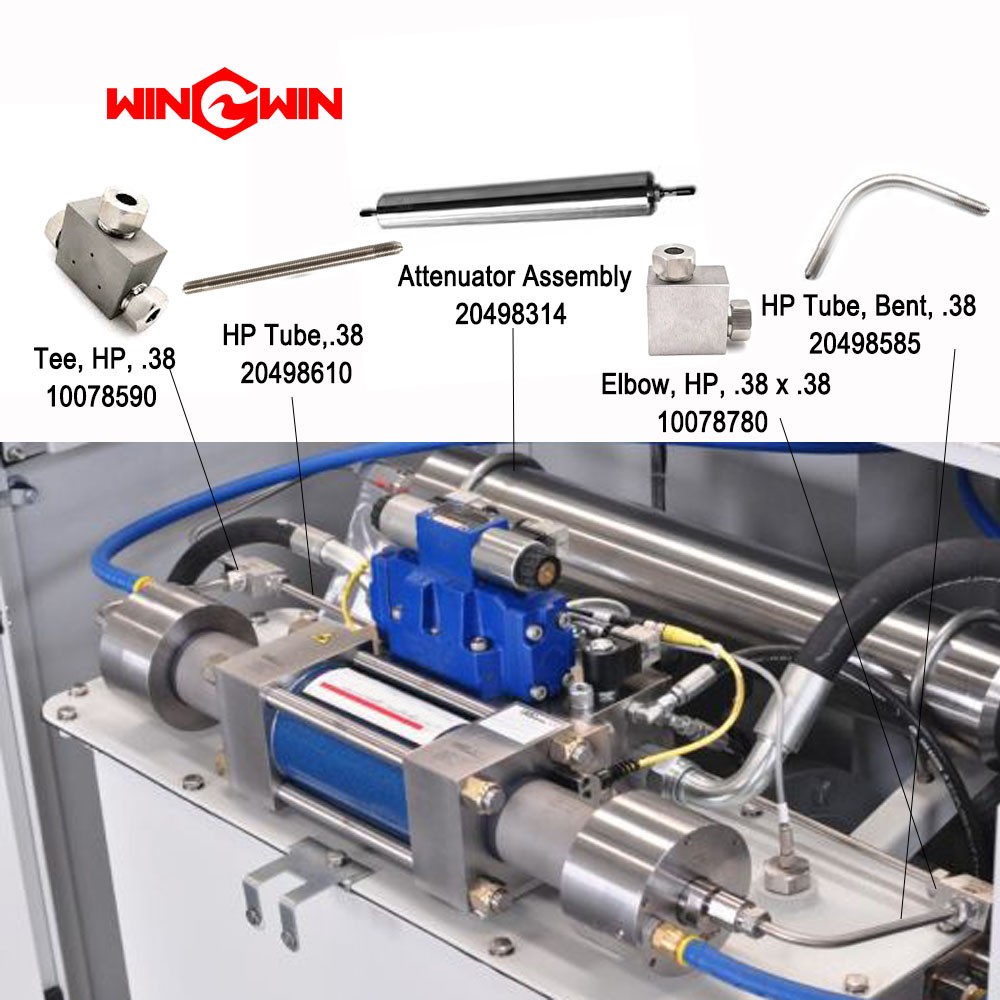

20498585 HP Tube Bent .38 for waterjet intensifier pump

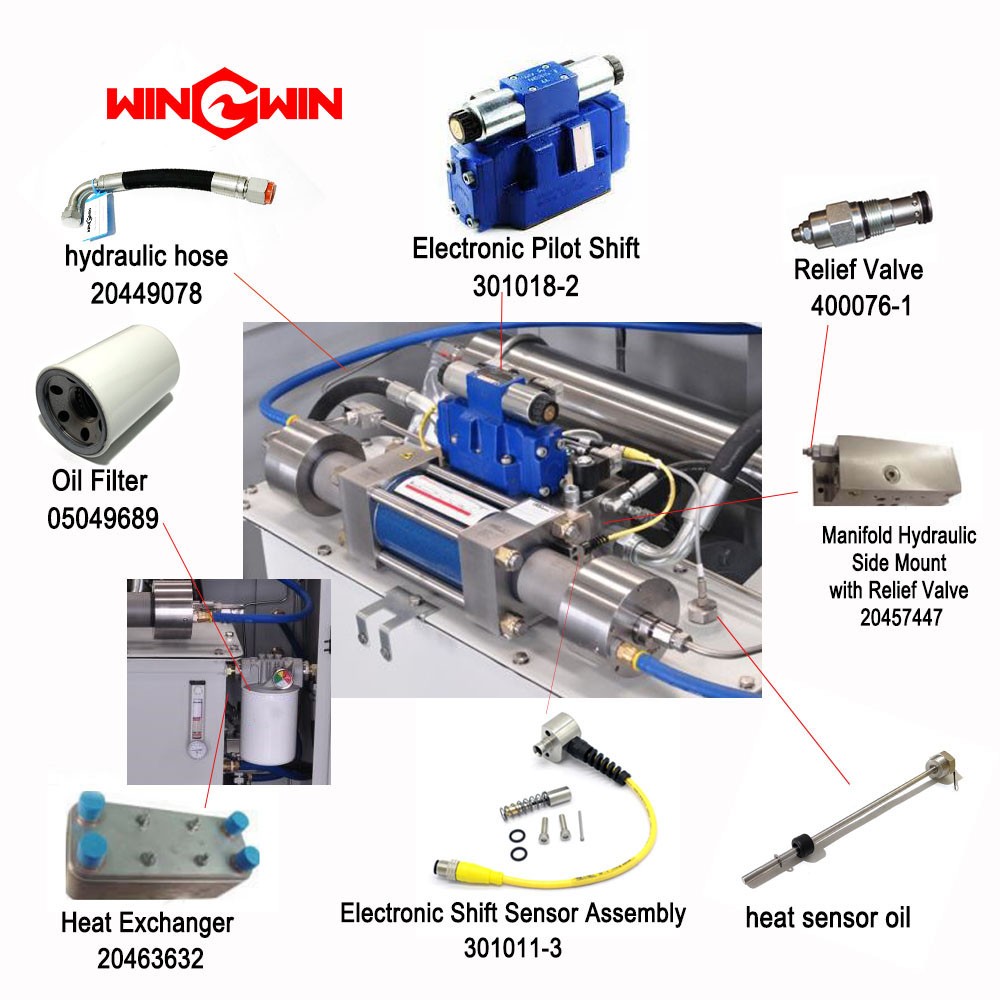

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

The intensifier pump is a critical component of a waterjet cutting machine, as it is responsible for generating the high-pressure water stream that is used to cut through various materials.

The intensifier pump works by pressurizing water through a series of hydraulic pistons and plungers, which can generate pressures of up to 90,000 pounds per square inch (psi) or more. This high-pressure water stream is then directed through a small orifice, which creates a narrow, focused beam of water that can cut through virtually any material.

The intensifier pump also plays a key role in controlling the flow rate and pressure of the water stream, which is important for ensuring accurate cuts and minimizing waste. Additionally, the pump may also include a number of safety features, such as pressure sensors and automatic shut-off valves, to prevent damage to the machine or injury to operators.

here are some additional details about the role of the intensifier pump in a waterjet cutting machine:

Generating high pressure: The primary function of the intensifier pump is to generate a high-pressure water stream that can cut through various materials. The pump uses a hydraulic system to compress the water to extremely high pressures, typically in the range of 30,000 to 90,000 psi or more, depending on the application.

Controlling water flow: In addition to generating high pressure, the intensifier pump also plays a key role in controlling the flow rate of the water stream. This is important for achieving accurate cuts and minimizing waste, as well as for optimizing the cutting speed and efficiency of the machine.

Maintaining pressure: The intensifier pump is designed to maintain a constant pressure in the water stream, even as the flow rate and other cutting parameters may change. This is accomplished through the use of pressure sensors and feedback control systems that adjust the flow of water through the pump as needed to maintain a consistent pressure at the cutting nozzle.

Ensuring safety: The intensifier pump may also include a number of safety features to protect the operator and the machine from damage. For example, the pump may have automatic shut-off valves that prevent the water stream from exceeding a certain pressure, or pressure relief valves that release excess pressure in the system to prevent damage or failure.

Maintenance and repair: Like any machine, the intensifier pump requires regular maintenance and occasional repair to ensure reliable operation. This may include replacing worn or damaged seals, checking and adjusting fluid levels, and inspecting and cleaning the pump components to prevent clogs or other issues. Regular maintenance can help extend the life of the pump and reduce downtime due to breakdowns or malfunctions.

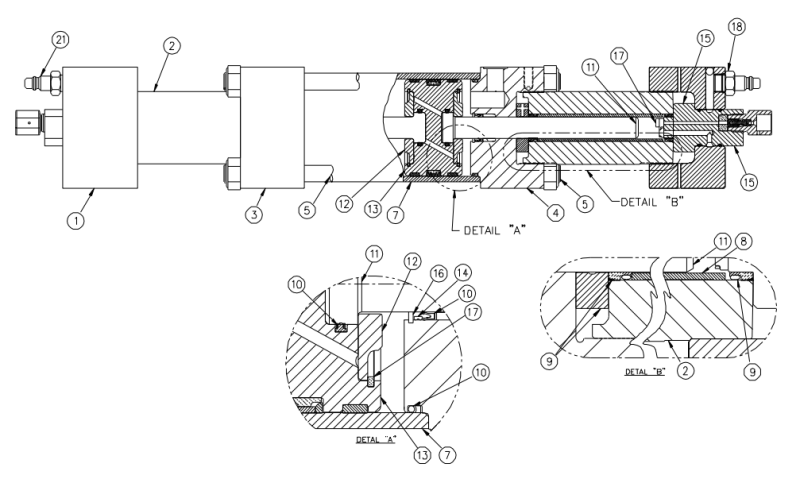

| Item | Part Number | Description | Item | Part Number | Description |

| 1 | 20458305 | End Cap | 12 | 20458062 | Plunger Retainer |

| 2 | 20457399 | High Pressure Cylinder | 13 | 20458869 | Hydraulic Piston Assembly |

| 3 | 20458299 | End Bell, LH | 20457966 | Hydraulic Piston | |

| 4 | 20458302 | End Bell, RH | 20458821 | Rebuild Kit, Piston Rings | |

| 5 | 20458191 | Tie Rod | 20460216 | Seal | |

| 6 | 20460489 | Hex Nut | 14 | 20458170 | Spacer, Hydraulic Seal |

| 7 | 20457414 | Hydraulic Cylinder | 15 | 20458908 | Sealing Head Assembly |

| 8 | 20458161 | Backup Sleeve | 16 | 20460252 | Snap Ring |

| 9 | 20458773 | Rebuild Kit, High Pressure Seal Assembly | 17 | 05202930 | Snap Ring |

| 20457990 | Seal Buttress | 18 | 20457267 | Inlet Water Nipple | |

| 20458113 | High Pressure Seal | 20457159 | Adapter, Quick Disconnect | ||

| 20457393 | Seal Hoop | 20459025 | O-Ring, Quick Disconnect | ||

| 20460108 | O-Ring | 11 | 20457912 | Plunger | |

| 10 | 20458797 | Rebuild Kit, Hydraulic Seal Assembly |

wwaterjet

wwaterjet