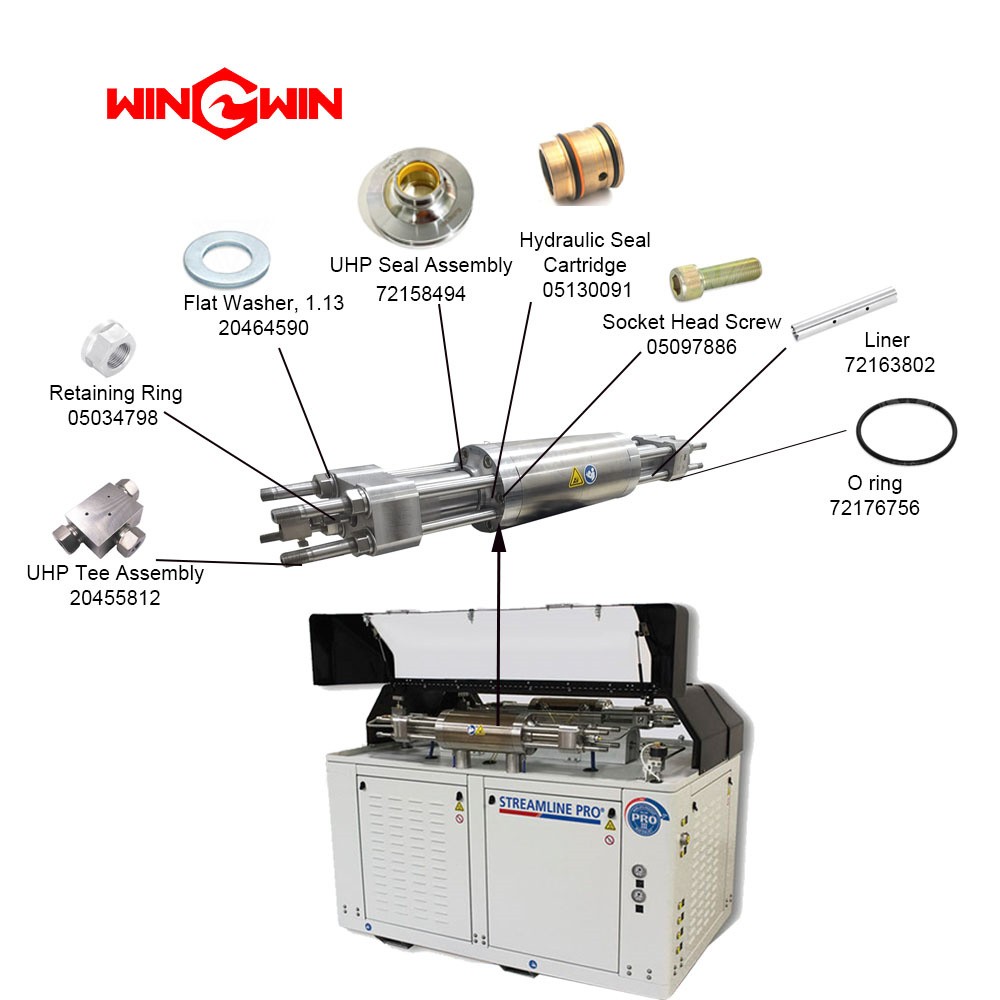

20451557 UHP adapter for 90000psi waterjet pump

Win Win waterjet provide many kinds of waterjet parts, OEM/ODM available

The cost of waterjet cutting can vary depending on several factors, including the specific application, the material being cut, the machine used, and the location of the service provider. However, here's how the cost of waterjet cutting compares to other common cutting methods:

Laser cutting: Laser cutting is generally more expensive than waterjet cutting for thinner materials. However, for thicker materials, laser cutting may be more cost-effective due to the increased cutting speed and efficiency.

Plasma cutting: Plasma cutting is generally less expensive than waterjet cutting for thicker materials. However, for thinner materials, waterjet cutting may be more cost-effective due to the higher precision and versatility.

Sawing: Sawing is generally less expensive than waterjet cutting for straight cuts in thicker materials. However, waterjet cutting may be more cost-effective for complex shapes or smaller production runs.

Punching: Punching is generally less expensive than waterjet cutting for sheet metal and other thin materials. However, waterjet cutting may be more cost-effective for thicker materials or for complex shapes that cannot be punched.

Overall, the cost of waterjet cutting is generally competitive with other cutting methods, especially when considering the precision, versatility, and environmentally friendly nature of waterjet cutting. While waterjet cutting may be more expensive than some traditional cutting methods, such as sawing or punching, it may be more cost-effective in the long run due to the reduced waste, increased precision, and versatility. Additionally, the abilityto cut a wide range of materials, including hard metals, stone, and composites, can result in cost savings by eliminating the need for multiple cutting methods. The cost-effectiveness of waterjet cutting will depend on the specific application and material being cut, and it's important to consider all factors, including the initial cost, operating costs, and production volume, when choosing a cutting method.

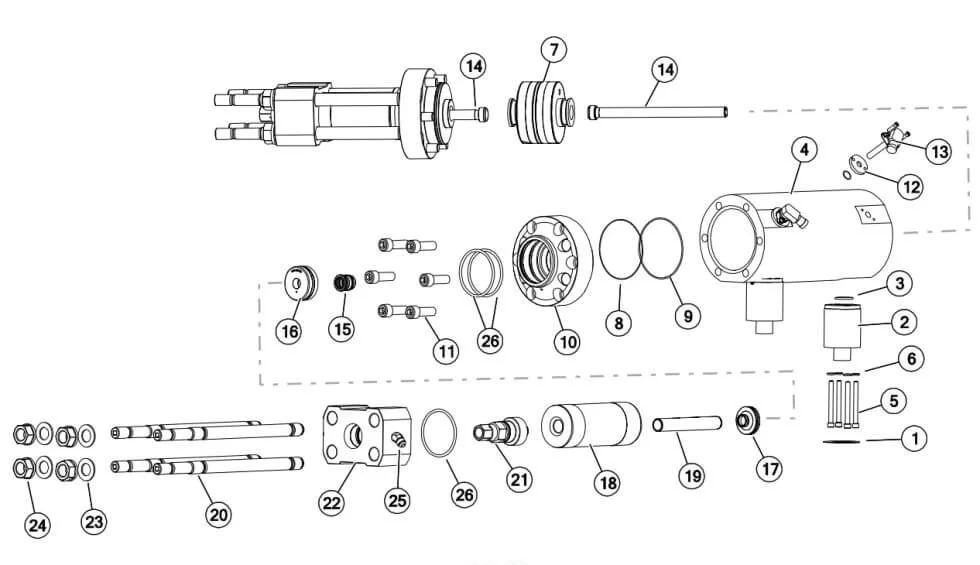

| Item | Part Number | Description | Item | Part Number | Description |

| 1 | 5146592 | Gasket, Topworks Support | 14 | 72162253 | Plunger |

| 2 | 20476377 | Support, Topworks | 15 | 5130091 | Hydraulic Seal Cartridge |

| 3 | 10118206 | O-Ring, 1.31×1.56× .13 | 16 | 72175989 | Bushing Retainer Flange |

| 4 | 5144514 | Hydraulic Cylinder | 17 | 72158494 | UHP Seal Assembly |

| 5 | 5098991 | Socket Head Screw, 3/8-16×3-3/4 | 18 | 72166738 | UHP Cylinder |

| 6 | 95688743 | Lock Washer, .38 | 19 | 72163802 | Liner |

| 7 | 72101190 | Piston Assembly | 20 | 20474325 | Stud, 1-1/8-12×18.31 |

| 8 | 10074771 | O-Ring, 5.25×5.50× .13 | 21 | 72170157 | Sealing Head Assembly |

| 9 | 5120092 | Backup Ring, 5.25×5.50× .13 | 22 | 72178493 | Flange Assembly |

| 10 | 72175997 | Hydraulic Cylinder Head | 23 | 20464590 | Flat Washer, 1.13 |

| 11 | 5097886 | Socket Head Screw, 3/4-16×2-1/4 | 24 | 20461761 | Hex Nut, 1-1/8-12 |

| 12 | 5144183 | Spacer Assembly, Proximity Switch | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 |

| 5144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | |

| 13 | 72141569 | Kit, Proximity Switch | 95119012 | Socket Head Screw, 1/4-20×1 | |

| 72134224 | Proximity Switch |

wwaterjet

wwaterjet