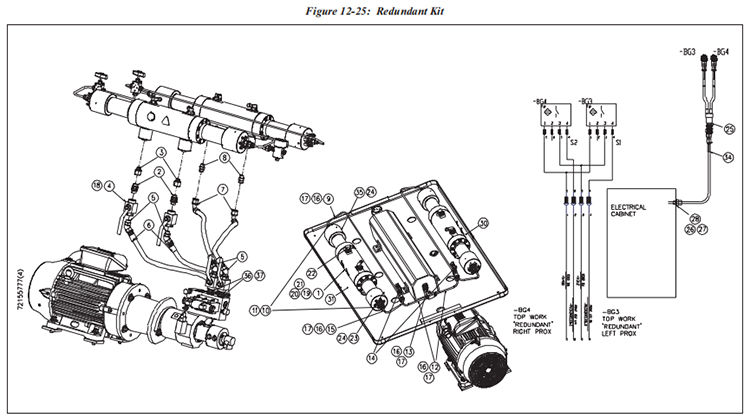

Table 12-35 Redundant Kit 72155777 | |||

Item | Part Number | Description | Quantity |

1 | 72160849 | Intensifier Topworks | 1 |

2 | 05057542 | Coupling, ORB, .75 x .75 | 2 |

3 | 05073176 | Bushing, ORB, .75 x .63 | 2 |

4 | 05070750 | Ball Valve Assembly | 4 |

5 | 05073168 | Adapter, JIC/ORB, .75 x .75 | 4 |

6 | 72129242 | Hydraulic Hose Assembly, .75 x 30.0 | 2 |

7 | 05071105 | Hydraulic Hose Assembly, .75 x 41.0 | 2 |

8 | 05073150 | Adapter, JIC/ORB, .75 x .63 | 2 |

9 | 72160906 | HP Tube, Bent, .38 | 1 |

10 | 10078129 | HP Gland, .38 | 2 |

11 | 10078715 | HP Collar, .38 | 2 |

12 | 72154041 | HP Tube, Bent, .38 | 2 |

13 | 10122315 | HP Tube, .38 x 4.50 | 1 |

14 | 10097533 | HP Valve Assembly | 2 |

15 | 72154033 | HP Tube, Bent, .38 | 1 |

16 | 10083897 | Ferrule, Hose, .25 | 10 |

17 | 10186153 | Flexible Conduit, .38 | 105.0" |

18 | 20451641 | Latch Pin | 4 |

19 | 95413696 | Lock Washer, .50 | 4 |

20 | 49898729 | Flat Washer, M12 | 4 |

21 | 95383790 | Socket Head Screw, 1/2-13 x 1 | 4 |

22 | 20417552 | Connector, Plug | 2 |

23 | 20448888 | Adapter, JIC/Pipe, .50 x .25 | 1 |

24 | 10189025 | Adapter, Hose/JIC, .50 x .50 | 2 |

25 | 72136124 | Cable Assembly, 4 Socket | 1 |

26 | 20465070 | Connector, Cable, .50 | 1 |

27 | 10083012 | Lock Nut, .50 | 1 |

28 | 10082857 | Gasket Assembly, .50 | 1 |

30 | 05076096 | Decal, Intensifier I | 1 |

31 | 05076104 | Decal, Intensifier II | 1 |

33 | 10083012 | Lock Nut, .50 | 1 |

34 | 72171665 | Cable, Pigtail | 1 |

35 | 05111406 | Adapter, JIC/Pipe, .50 x .25 | 1 |

36 | 05070743 | Adapter, JIC/ORB, .75 x .75 | 2 |

37 | 95702619 | Adapter, JIC/ORB, .75 x .75 | 2 |

38 | 10170371 | Connector, Crimp Pin, #18 | 4 |

39 | 10099026 | Ring Terminal | 1 |

A waterjet redundant kit typically refers to a backup or duplicate system designed to provide redundancy in critical applications where continuous operation is essential. In the context of a waterjet system, such a kit would likely include redundant components necessary for the operation of the waterjet equipment, ensuring that if one component fails, another can seamlessly take over to prevent downtime.

Here's what might be included in a waterjet redundant kit:

1. Redundant Pump: The heart of a waterjet system is the pump, which pressurizes water to high levels for cutting or other applications. A redundant kit may include a backup pump that can quickly take over in case the primary pump fails. This ensures uninterrupted operation of the waterjet system.

2. Redundant Nozzle Assembly: The nozzle is the component through which the high-pressure water exits the system for cutting or cleaning. A redundant kit may include a spare or backup nozzle assembly so that if the primary nozzle becomes damaged or clogged, it can be quickly replaced without halting operations.

3. Redundant High-Pressure Lines and Fittings: The high-pressure lines and fittings are critical for delivering pressurized water from the pump to the nozzle. A redundant kit may include spare lines and fittings so that if a line ruptures or a fitting fails, it can be swiftly replaced to maintain system integrity.

4. Redundant Control System Components: This might include redundant control units, switches, sensors, or other electronic components necessary for the operation of the waterjet system. Redundant control system components help ensure that if a component fails, the system can continue to function without interruption.

5. Emergency Shutdown Mechanism: A redundant emergency shutdown mechanism might be included in the kit to quickly stop the waterjet system in the event of a malfunction or emergency situation.

6. Spare Parts and Consumables: The kit may also include spare parts and consumables such as seals, o-rings, filters, and other components that are prone to wear and may need replacement during operation.

7. Documentation and Training Materials: Comprehensive documentation and training materials may be provided to guide operators on the proper use of the redundant kit and how to perform maintenance or troubleshooting tasks in the event of a failure.

Overall, a waterjet redundant kit provides peace of mind in critical applications by ensuring that the system can continue operating even in the event of component failure, minimizing downtime and maintaining productivity.

wwaterjet

wwaterjet