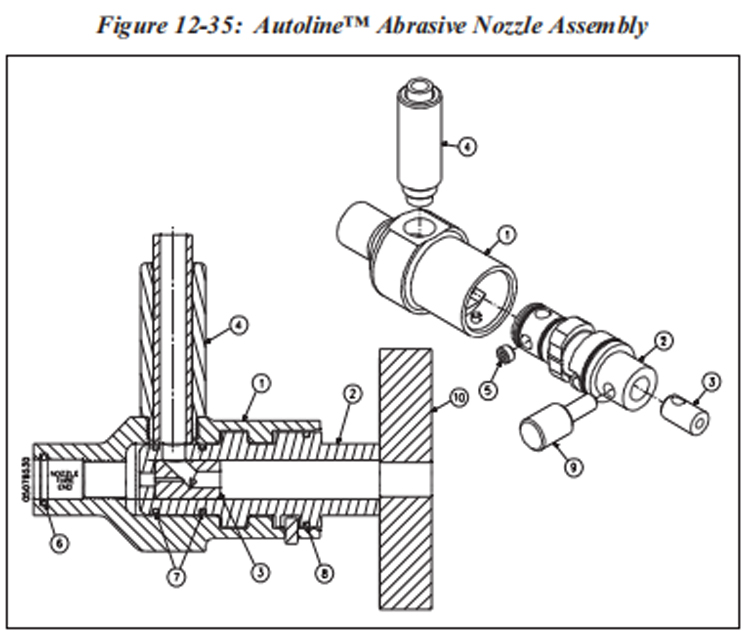

Table 12-45 Autoline™ Abrasive Nozzle Assembly | |||

Item | Part Number | Description | Quantity |

05078530 | AutolineTM Nozzle Assembly, .030 Wear Insert | ||

05147970 | AutolineTM Nozzle Assembly, .043 Wear Insert | ||

1 | 05076971 | Nozzle Cap | 1 |

2 | 05073820 | Nozzle Body | 1 |

3 | 05076955 | Wear Insert, .030 x .156 | 1 |

05135827 | Wear Insert, .043 x .156 | ||

4 | 05076989 | Feed Tube Adapter | 1 |

5 | 05077292 | Setscrew, 1/4-28 | 1 |

6 | 05081518 | O-Ring, .38 x .50 x .06 | 1 |

7 | 05104930 | O-Ring, .50 x .63 x .06 | 2 |

8 | 05092887 | O-Ring, .75 x .63 x .06 | 1 |

9 | 05078712 | Retainer Knob | 1 |

10 | 05087168 | Guard | 1 |

49885361 | Poly Tube, .38 | ||

The Waterjet Autoline™ Abrasive Nozzle Assembly is a key component in a waterjet cutting system that incorporates abrasive materials into the high-pressure water stream. Here are some key points about the Autoline™ Abrasive Nozzle Assembly:

1. Function: The Autoline™ Abrasive Nozzle Assembly is designed to mix abrasive materials, typically garnet or other abrasive particles, with the high-pressure water stream just before it exits the nozzle.

2. Abrasive Addition: It allows for precise control over the addition of abrasives into the waterjet stream, enhancing the cutting power and effectiveness, especially for harder materials like metal, stone, and ceramics.

3. Nozzle Design: The assembly comprises a specially designed nozzle that enables the introduction of the abrasive material into the waterjet stream. This nozzle is engineered to ensure proper mixing and dispersion of the abrasive particles within the water flow.

4. Compatibility: The Autoline™ Abrasive Nozzle Assembly is designed to be compatible with specific waterjet cutting systems, ensuring seamless integration and functionality within the cutting head assembly.

5. Efficiency: By introducing abrasives at the last stage before the waterjet exits the nozzle, the assembly optimizes the cutting process, enhancing the system's efficiency in cutting through tough materials.

6. Precision Cutting: The addition of abrasives to the waterjet stream allows for more precise and faster cutting of various materials, resulting in clean and accurate cuts with reduced taper and improved edge quality.

7. Maintenance: Proper maintenance of the abrasive nozzle assembly is crucial to ensure consistent and reliable performance. Regular cleaning and inspection help prevent clogging and maintain optimal cutting efficiency.

The Autoline™ Abrasive Nozzle Assembly is a vital component that enhances the cutting capabilities of waterjet systems, especially when dealing with harder materials that require increased cutting power. Its efficient design and precise control over abrasive addition contribute to improved cutting performance and accuracy.

wwaterjet

wwaterjet