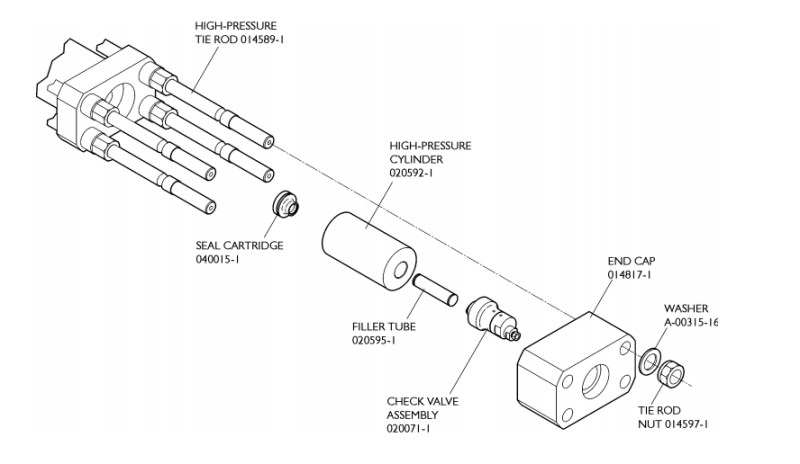

014817-1 87K INTENSIFIER END CAP ASSEMBLY

When choosing a waterjet cutting machine pump, there are several factors to consider, including:

Pressure rating: The pressure rating of the pump is an important factor to consider, as it directly affects the cutting speed and the thickness of the materials that can be cut. Higher pressure pumps can cut through thicker materials and at faster speeds than lower pressure pumps.

Power output: The power output of the pump will determine the speed and accuracy of the cutting process. Higher power pumps can cut through materials faster and with greater precision.

Pump efficiency: The efficiency of the pump is important to consider, as a more efficient pump will use less energy and produce less waste, resulting in lower operating costs.

Reliability and durability: The reliability and durability of the pump are essential factors to consider, especially for industrial applications where downtime can be costly. A well-built pump with high-quality components will be more reliable and last longer.

Maintenance requirements: The maintenance requirements of the pump should also be considered, as regular maintenance is necessary for optimal performance and longevity. Some pumps may require more frequent maintenance than others, which can impact operating costs and downtime.

Compatibility with the cutting machine: It's important to ensure that the pump is compatible with the cutting machine, as not all pumps will work with all machines. Compatibility can impact the cost of installation and overall performance of the system.

when choosing a waterjet cutting machine pump, it's important to consider the pressure rating, power output, efficiency, reliability, maintenance requirements, and compatibility with the cutting machine to ensure optimal performance and cost-

wwaterjet

wwaterjet